Milling machines are among the most important and widely used machine tools in modern manufacturing. From simple workshop operations to advanced aerospace component production, milling plays a crucial role in shaping raw materials into precise, functional parts.

Understanding what a milling machine is, how it works, and where it is applied helps manufacturers, engineers, and designers choose the most suitable machining solutions. With the evolution from manual milling to sophisticated multi-axis CNC machining centers, milling technology has become faster, more accurate, and more versatile than ever before.

This article provides a comprehensive and in-depth guide to milling machines, covering their definition, historical development, working principles, technical parameters, types, operations, tools, materials, applications, advantages, limitations, cost considerations, safety issues, and selection criteria.

What Is a Milling Machine?

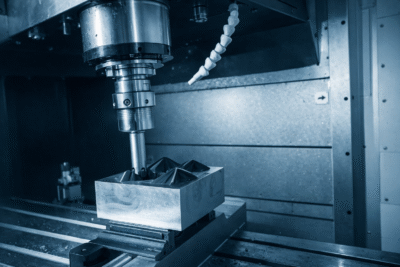

A milling machine is a machine tool that removes material from a stationary workpiece using a rotating cutting tool. The cutting tool typically has multiple cutting edges and removes material progressively as it rotates and advances into the workpiece.

Milling is a subtractive manufacturing process, meaning material is removed from a solid block to create the desired geometry. Milling machines can be operated:

Manually, where the operator controls tool movement

Automatically, using Computer Numerical Control (CNC)

Because cutting tools can be changed easily, milling machines are capable of performing a wide range of operations such as surface machining, slotting, drilling, contouring, and gear cutting. This versatility makes milling machines a core asset in almost every machining workshop.

History of Milling Machines

Before milling machines were invented, parts were shaped manually using hand tools such as files and chisels. This process was slow, labor-intensive, and highly dependent on operator skill.

The first true milling machine is widely attributed to Eli Whitney, who developed it in 1818 in New Haven, Connecticut. His motivation was to produce interchangeable firearm parts for government contracts, a requirement that demanded high precision and repeatability.

Over time, milling machines evolved through several stages:

Early mechanical and belt-driven mills

Electrically powered machines

Introduction of tracer-controlled systems

Development of numerical control (NC)

Modern CNC milling machines with multi-axis capability

Today, milling machines are fully integrated with CAD/CAM software, automation systems, and digital manufacturing workflows.

Uses of a Milling Machine

Milling machines are used to perform a wide variety of machining tasks, including:

Machining flat and curved surfaces

Drilling, boring, and reaming holes

Cutting slots, grooves, and keyways

Thread milling

Gear manufacturing

Complex 3D surface machining

Due to their adaptability, milling machines are used for prototyping, small-batch production, and large-scale mass manufacturing across many industries.

Main Components of a Milling Machine

Although milling machines vary in design, most share the following core components:

Base

The base supports the entire machine structure. It is typically made from cast iron to provide rigidity and vibration damping.

Column

The column is the vertical frame that houses internal drive mechanisms and supports moving components.

Knee

Mounted above the base, the knee supports the saddle and table. It moves vertically along the column.

Saddle

The saddle sits on the knee and enables transverse (Y-axis) movement of the worktable.

Worktable

The worktable holds the workpiece using clamps or fixtures. It usually provides longitudinal (X-axis) movement.

Spindle

The spindle holds and rotates the cutting tool. In advanced machines, it can rotate along multiple axes.

Arbor

The arbor is a tool-holding component used mainly in horizontal milling machines.

Headstock

The headstock houses the spindle drive motor and transmission system.

Overarm

The overarm supports the spindle and arbor assembly, improving rigidity.

How Milling Machining Works

Part Design

The process begins with part design. For CNC milling, CAD models are converted into machining instructions using CAM software. Manual milling uses technical drawings and blueprints.

Machine Setup

The machine is configured with appropriate tools, spindle speed, feed rate, and depth of cut. CNC machines receive programs directly through the control system.

Workpiece Fixturing

The workpiece is securely clamped to prevent vibration and movement, which can damage tools or reduce accuracy.

Milling Operation

The rotating cutting tool removes material incrementally along predefined toolpaths. The feed rate determines how quickly the tool advances into the workpiece.

Inspection and Quality Control

After machining, parts are inspected for dimensional accuracy and surface quality. Additional machining passes may be performed if required.

Technical Parameters of a Milling Machine

Key technical parameters include:

Spindle Speed (n): Rotational speed of the tool (RPM)

Tool Diameter (Dc): Affects cutting forces and material removal rate

Cutting Speed (Vc): Linear speed at the cutting edge

Vc = π × Dc × n ÷ 1000

Feed Rate (Vf): Tool advancement speed into the workpiece

Depth of Cut (ap): Tool penetration depth, affecting tool wear and surface finish

Optimizing these parameters is critical for machining efficiency and tool life.

Types of Milling Machines

Based on Spindle Orientation

Vertical Milling Machines – Spindle oriented vertically; highly versatile

Horizontal Milling Machines – Spindle oriented horizontally; better for heavy cutting

Universal Milling Machines – Capable of both vertical and horizontal operations

Based on Number of Axes

3-axis – X, Y, Z linear movement

4-axis – Adds one rotary axis

5-axis – Two rotary axes for complex geometry

6-axis – Full spatial machining without repositioning

Based on Machine Structure

Fixed bed mills

Knee-type mills

Planer-type mills

C-frame mills

Traveling column mills

Gantry mills

Based on Control Method

Manual milling machines

Tracer-controlled machines

DRO milling machines

CNC milling machines

Milling Machine Operations

Common milling operations include:

Slab and face milling

End milling

Up milling and down milling

Slot, groove, and side milling

Form, profile, and contour milling

Gear, thread, cam, and angle milling

Plunge and peripheral milling

Face milling is the most widely used operation due to its versatility and surface quality.

Materials That Can Be Machined Using Milling Machines

Milling machines can cut:

Metals and alloys: steel, aluminum, titanium, brass, copper

Plastics: ABS, nylon, HDPE

Ceramics and glass

Composites: carbon fiber, FRP

Wood and engineered materials

Cutting Tools Used in Milling

Common milling tools include:

End mills

Face mills

Slab mills

Ball nose cutters

Slot drills

Fly cutters

Thread mills

Chamfer mills

T-slot cutters

Tool selection directly affects machining accuracy and surface finish.

Applications of Milling Machines

Milling machines are used in:

Automotive manufacturing

Aerospace and defense

Electronics and semiconductor production

Mold and die making

Medical and dental industries

Construction and energy sectors

Research, development, and prototyping

Advantages and Limitations of Milling Machines

Advantages

High versatility

Excellent dimensional accuracy

Consistent and repeatable results

Automation compatibility

Wide material compatibility

Superior surface finish

Limitations

High initial investment

Large space requirements

Tooling complexity

Limited access to bottom surfaces

Cost and Service Life of Milling Machines

New milling machines typically cost USD 10,000 to over USD 200,000, depending on size, axes, brand, and control system.

With proper maintenance, milling machines can operate reliably for 10–15 years or more.

Maintenance of Milling Machines

Milling machines are relatively easy to maintain when:

Manufacturer maintenance schedules are followed

Lubrication systems are properly serviced

Wear components are replaced periodically

Factors to Consider When Selecting a Milling Machine

Key selection factors include:

Control system (manual vs. CNC)

Machine type and configuration

Workpiece size and geometry

Machine power and rigidity

Budget constraints

Build quality and brand reputation

Where to Buy or Access Milling Machines

Options include:

Online machine tool suppliers

Local distributors and manufacturers

Used or refurbished equipment

Outsourcing to CNC milling service providers

Operating Difficulty and Skill Requirements

Operating a milling machine is not inherently difficult, but it requires:

Technical knowledge

Tooling experience

Safety awareness

CNC milling significantly reduces manual skill requirements but increases programming complexity.

Safety Hazards and Risks of Milling Machines

Potential hazards include:

Contact with rotating cutting tools

Flying chips and debris

Electrical risks

Noise and vibration exposure

Proper guarding, personal protective equipment, and safety training are essential.

Conclusion

Milling machines have revolutionized modern manufacturing by enabling precise, efficient, and repeatable material removal across a wide range of industries. From simple manual mills to advanced multi-axis CNC systems, milling remains a cornerstone of industrial production, prototyping, and innovation.

Choosing the right milling machine—and using it correctly—can significantly improve product quality, production efficiency, and manufacturing competitiveness. Contact us for more information.

FAQs

1. What is the difference between conventional milling and climb milling?

Conventional milling (up milling) occurs when the cutting tool rotates against the direction of feed, causing gradual chip thickness. Climb milling (down milling) happens when the cutter rotates in the same direction as the feed, producing a smoother surface finish and longer tool life. Climb milling is commonly used in CNC machining, while conventional milling is often preferred on manual machines due to safety considerations.

2. How accurate is CNC milling compared to manual milling?

CNC milling is significantly more accurate than manual milling. Typical CNC milling machines can achieve tolerances of ±0.005 mm or better, depending on machine quality and setup. Manual milling accuracy is largely dependent on operator skill and generally cannot match the consistency and repeatability of CNC systems.

3. What factors most affect tool wear in milling operations?

Tool wear in milling is influenced by several factors, including cutting speed, feed rate, depth of cut, tool material, workpiece material, and cooling conditions. Improper parameter selection or insufficient lubrication can rapidly reduce tool life and compromise surface quality.

4. Can milling machines perform drilling and tapping operations?

Yes, milling machines can perform drilling, tapping, reaming, and boring operations. CNC milling machines are particularly effective at combining these processes into a single setup, improving accuracy and reducing production time by eliminating the need for multiple machines.

5. What role does coolant play in milling operations?

Coolant helps reduce cutting temperature, lubricate the cutting zone, remove chips, and extend tool life. Depending on the application, milling machines may use flood coolant, mist coolant, or dry machining. The choice depends on material type, tool geometry, and environmental considerations.

6. How does machine rigidity affect milling performance?

Machine rigidity directly impacts surface finish, dimensional accuracy, and tool life. A rigid milling machine minimizes vibration and chatter during cutting, allowing higher cutting speeds and deeper cuts. This is especially critical for machining hard materials and maintaining tight tolerances.

7. Is milling suitable for high-volume mass production?

Yes, milling—especially CNC milling—is suitable for high-volume production when combined with automation, pallet changers, and optimized toolpaths. However, for extremely high-volume and simple geometries, processes like injection molding or die casting may be more cost-effective.

8. How do I choose between a vertical machining center (VMC) and a horizontal machining center (HMC)?

A vertical machining center is ideal for general-purpose machining, prototyping, and smaller parts due to easier setup and lower cost. A horizontal machining center is better suited for large-scale production, heavy material removal, and complex multi-face machining, as it offers improved chip evacuation and higher productivity.