Oxygen is essential for life on Earth, yet it is also one of the most aggressive and destructive elements when it comes to metals. Left unprotected, many metals will slowly but relentlessly degrade through corrosion, eventually leading to structural failure, performance loss, and costly replacements. As the saying goes, rust never sleeps.

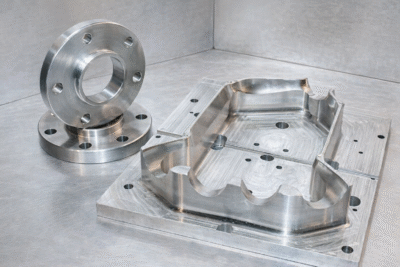

In industrial, commercial, and engineering applications, corrosion is not a cosmetic issue—it is a design, safety, and lifecycle cost problem. From CNC-machined components and sheet metal enclosures to aerospace parts and medical devices, selecting the right corrosion-resistant metal is critical to ensuring durability, reliability, and long-term value.

The good news is that modern manufacturing offers a wide range of corrosion-resistant metals that can be CNC machined, die casted, or 3D printed into precision components. This guide explains how corrosion resistance works, which metals perform best, and how to choose the right material for your application.

Why Corrosion Happens—and Why It Matters

Corrosion is an electrochemical reaction between a metal and its environment. Moisture, oxygen, salts, chemicals, and temperature fluctuations all accelerate this process. In the case of carbon steel and iron, corrosion produces rust—iron oxide—which flakes away and exposes fresh metal underneath, allowing the process to continue indefinitely.

This matters because corrosion:

Reduces mechanical strength

Shortens part lifespan

Increases maintenance and replacement costs

Causes safety risks in load-bearing structures

Leads to premature product failure

In harsh environments—such as marine, chemical, outdoor, medical, or high-temperature applications—corrosion resistance is not optional. It is a fundamental material requirement.

How Corrosion-Resistant Metals Work: Passivation Explained

Not all oxidation is destructive. Many corrosion-resistant metals form a passivation layer, a thin, stable oxide film that bonds tightly to the metal surface and prevents further corrosion.

Key characteristics of passivation layers:

They are self-healing when scratched

They block oxygen and moisture from penetrating deeper

They do not flake or peel like rust

This is the fundamental difference between carbon steel and corrosion-resistant metals such as aluminum, stainless steel, and titanium.

Key Factors When Choosing a Corrosion-Resistant Metal

No single metal is ideal for every application. Engineers and buyers should evaluate materials based on:

Corrosion environment (humidity, saltwater, chemicals, heat)

Mechanical strength requirements

Weight constraints

Machinability and fabrication method

Cost and availability

Electrical or thermal conductivity needs

Below is a detailed breakdown of the most commonly used corrosion-resistant metals in modern manufacturing.

Aluminum: Lightweight, Versatile, and Naturally Corrosion Resistant

Aluminum is one of the most widely used corrosion-resistant metals across industries. When exposed to air, aluminum forms a thin but extremely hard layer of aluminum oxide, which protects the base metal from further oxidation.

Key Advantages of Aluminum

Excellent corrosion resistance

Lightweight with good strength

Non-magnetic

High electrical and thermal conductivity

Easy to machine, form, and fabricate

Common Aluminum Grades

6061-T651: General-purpose CNC machining and fabrication alloy

7075-T651: High-strength aerospace aluminum

5052-H32: Superior formability for sheet metal parts

AlSi10Mg: Popular aluminum alloy for metal 3D printing

Surface Treatments

While aluminum resists corrosion naturally, anodizing is often applied to improve durability, wear resistance, and appearance.

Typical Applications

Electronics housings

Machinery components

Aerospace structures

Enclosures and brackets

Scientific instruments

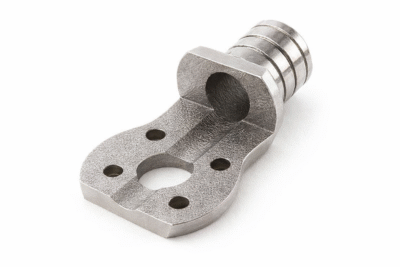

Titanium: Exceptional Corrosion Resistance with High Strength

Titanium is known for its outstanding strength-to-weight ratio and near-unmatched corrosion resistance. It forms a stable titanium oxide layer that protects it in extreme environments, including saltwater and many chemical exposures.

Why Choose Titanium?

Strong as steel but nearly half the weight

Superior corrosion resistance

Resistant to acids, saltwater, and chemicals

Biocompatible

Common Alloy

Ti-6Al-4V: The most widely used titanium alloy in machining and 3D printing

Typical Applications

Medical implants

Aerospace engines and structures

Power generation components

High-performance industrial parts

Titanium is more expensive than aluminum or stainless steel, but its performance often justifies the cost in critical applications.

Stainless Steel: A Balanced Solution for Strength and Corrosion Resistance

Stainless steel earns its name from chromium, which reacts with oxygen to form a protective chromium oxide layer. This makes stainless steel one of the most versatile corrosion-resistant materials available.

Common Stainless Steel Grades

303: Excellent machinability, moderate corrosion resistance

304 / 304L: General-purpose stainless steel

316 / 316L: Enhanced corrosion resistance due to molybdenum

17-4 PH: High strength, heat-treatable stainless steel

Typical Applications

Food and medical equipment

Chemical processing components

Aerospace and petrochemical parts

Structural and mechanical assemblies

Stainless steel offers an excellent balance of cost, strength, and corrosion performance.

Cobalt Chrome: Wear-Resistant and Biocompatible

Cobalt chrome alloys provide superior wear resistance and corrosion performance, particularly in demanding environments.

Key Properties

Higher strength and wear resistance than stainless steel

Excellent corrosion resistance

Biocompatible

Common Alloy

Co28Cr6Mo, typically produced via metal 3D printing

Typical Applications

Medical implants and prosthetics

Engine and furnace components

High-wear industrial parts

Inconel: Extreme Corrosion Resistance at High Temperatures

Inconel is a nickel-based superalloy designed for environments involving extreme heat, pressure, and corrosion.

Why Inconel Stands Out

Retains strength up to 1,300°F (700°C)

Excellent oxidation and corrosion resistance

Precipitation-hardenable

Common Alloy

Inconel 718

Typical Applications

Aerospace engines

Gas turbines

Energy and chemical processing equipment

Due to machining difficulty, Inconel is often produced using metal 3D printing (DMLS).

Brass: Easy Machining with Reliable Corrosion Resistance

Brass, an alloy of copper and zinc, offers good corrosion resistance combined with excellent machinability.

Common Brass Grades

C360: Free-cutting brass for high-volume machining

C260: Cartridge brass with excellent formability

Typical Applications

Plumbing fittings

Electrical connectors

Bearings and fasteners

Decorative and functional components

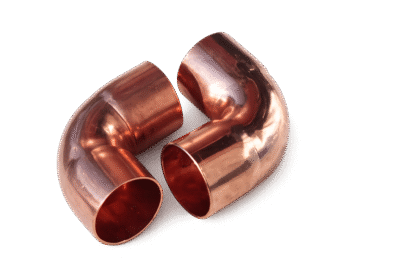

Copper: Conductivity with Natural Protection

Copper does not rust like steel. Instead, it forms a patina—a blue-green copper carbonate layer that protects the metal underneath.

Key Advantages

Exceptional electrical conductivity

Excellent thermal conductivity

Natural antimicrobial properties

Common Grades

C101

C110

Typical Applications

Heat exchangers

Electrical and electronic components

EMI shielding

Medical and hospital equipment

Manufacturing Methods for Corrosion-Resistant Metals

Corrosion-resistant metals can be produced using:

CNC turning and milling

Sheet metal fabrication

Metal 3D printing (DMLS)

Each material has different machinability and processing considerations that affect lead time and cost.

When Surface Treatments Are Still Necessary

Even corrosion-resistant metals often benefit from additional treatments:

Anodizing for aluminum

Passivation for stainless steel

Coatings for enhanced chemical or wear resistance

These processes extend service life and improve performance.

Alternatives: Polymers and Treated Steels

In some cases:

Engineering plastics may replace metal entirely

Carbon steel can be coated or plated for corrosion resistance

These options may reduce cost when environmental exposure is limited.

How to Choose the Right Corrosion-Resistant Metal

To select the optimal material:

Define the operating environment

Identify mechanical and thermal requirements

Balance performance with budget

Consult material data sheets and manufacturing experts

Conclusion: Design for Durability from the Start

Corrosion is unavoidable—but failure is not. By selecting the right corrosion-resistant metal and manufacturing process, engineers and buyers can dramatically extend part life, reduce maintenance costs, and improve product reliability.

Whether you need CNC-machined aluminum parts, stainless steel components, or metal 3D printed superalloys, choosing the right material early in the design phase is the key to long-term success.

If you are evaluating materials for your next project, working with an experienced manufacturing partner can help you optimize both performance and cost.

FAQs

1. What is the most corrosion-resistant metal?

Titanium is widely considered the most corrosion-resistant metal for industrial applications. It forms a stable titanium oxide layer that protects it from saltwater, acids, and many harsh chemicals. For extreme temperatures, nickel-based alloys such as Inconel also offer exceptional corrosion resistance.

2. Which metal is best for corrosion resistance and CNC machining?

Aluminum (especially 6061) and stainless steel (303 or 304) provide the best balance between corrosion resistance and machinability. They are easy to CNC machine, widely available, cost-effective, and suitable for most industrial and commercial environments.

3. Does stainless steel rust over time?

Stainless steel does not rust in the same way as carbon steel, but it can corrode under certain conditions. Chlorides, saltwater, and poor surface treatment can compromise its protective chromium oxide layer. Passivation and proper material selection (such as 316 stainless steel) significantly improve corrosion resistance.

4. Is aluminum corrosion resistant for outdoor use?

Yes, aluminum is naturally corrosion resistant due to its aluminum oxide passivation layer. For outdoor or marine environments, anodizing is recommended to enhance durability, improve wear resistance, and extend service life.

5. What is the difference between corrosion resistance and rust resistance?

Rust resistance specifically refers to iron-based metals resisting iron oxide formation. Corrosion resistance is broader and applies to all metals, including aluminum, titanium, copper, and stainless steel, which corrode differently but often form protective surface layers instead of flaking rust.

6. Do corrosion-resistant metals still need surface treatments?

In many applications, yes. While metals like aluminum and stainless steel resist corrosion naturally, surface treatments such as anodizing, passivation, or coating are often applied to improve longevity, appearance, and performance in aggressive environments.

7. What metal is best for marine or saltwater environments?

Titanium and 316 stainless steel are excellent choices for marine and saltwater applications. Both materials resist chloride-induced corrosion, making them suitable for offshore, coastal, and marine equipment.

8. How do I choose the right corrosion-resistant metal for my project?

The right metal depends on the operating environment, mechanical requirements, manufacturing method, and budget. Factors such as humidity, chemicals, temperature, weight, and machining complexity should all be considered. Consulting material data sheets and experienced manufacturing engineers helps ensure the optimal choice.