CNC Rapid Prototype Service at Sochain Precision

Get Precision CNC Prototype service that validates fit, function, and manufacturability

At Sochain Precision, rapid prototyping focuses on identifying such issues early on.

Our CNC Prototype Service produces parts using production-grade materials, controlled tolerances, and stable machining techniques.

Typical prototype lead times range from 5 to 7 working days.

This allows manufacturers and engineers to validate fit, function, and strength before investing in costly tooling, and result is faster design approval and fewer engineering change orders.

Rapid prototyping and full-scale production

ISO accredited & QC checks

All in-house processes

Used in over 50 countries

FREE Instant quotations

Why Choose Our CNC Prototype Service

A prototype supplier must eliminate engineering risk, not add to it. Our CNC Prototype Service includes comprehensive DFM analysis and manufacturability checks before machining. We identify sharp internal corners, unrealistic tolerances, and weak wall sections early. This allows us to prevent prototype failure and production delays.

10+ Years of Rapid Prototyping Experience

With over a decade of prototyping experience, we understand where designs fail under actual conditions. We’ve machined 1000s of prototype parts across metals and engineering plastics. This experience allows us to suggest tolerance optimization, material substitutions, and feature adjustments that improve performance without adding cost.

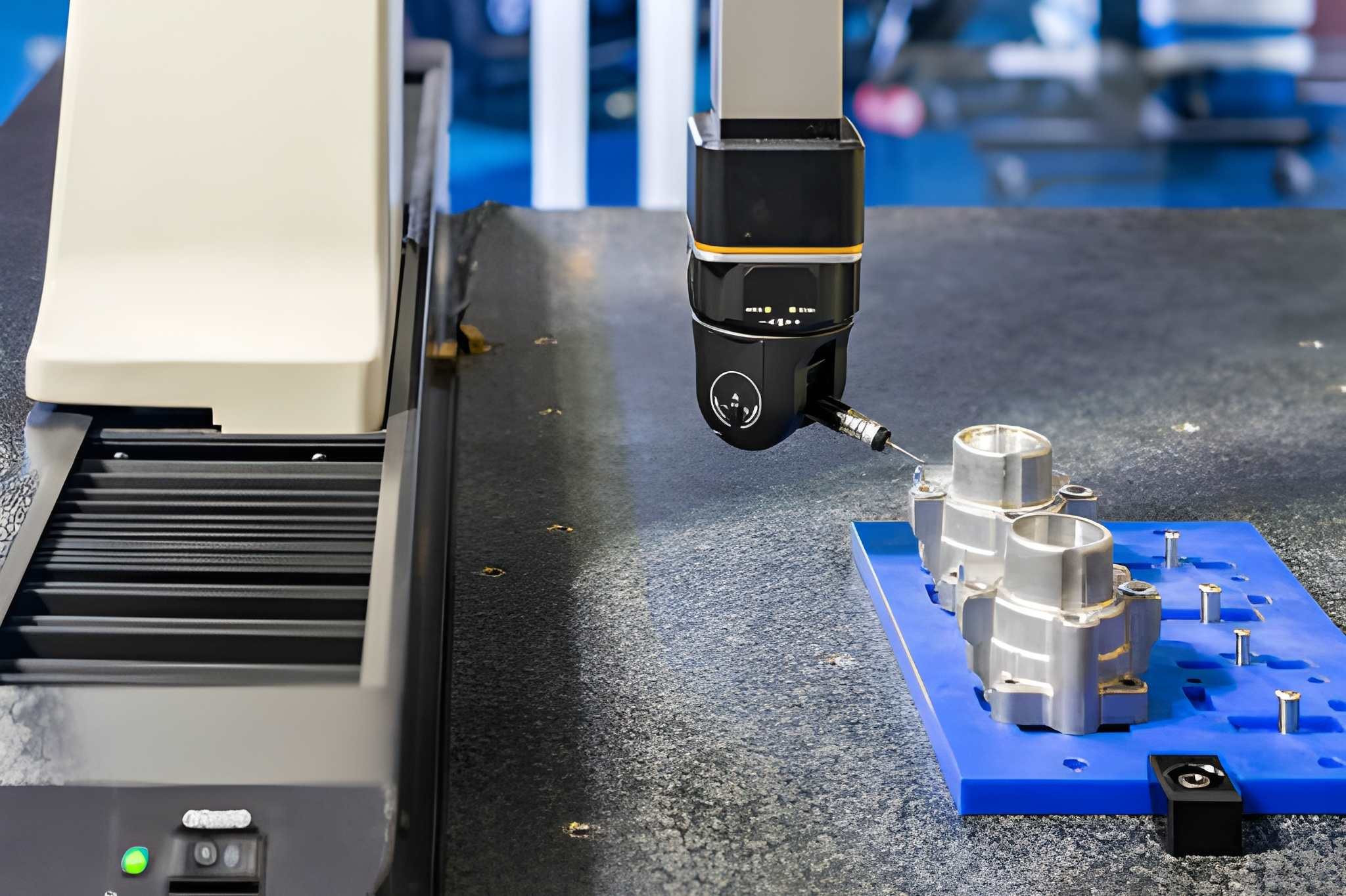

ISO 9001 & ISO 13485 Certified Manufacturing

Quality control is enforced through documented procedures. Our CNC Prototype Service follows ISO 9001 and ISO 13485 standards for inspection and traceability. Critical dimensions are measured using calibrated CMMs and precision gauges. Clients can request inspection reports for functional and regulated applications.

Competitive Pricing

Our advanced CNC equipment reduces setup time and scrap. We optimize tool paths and fixtures to minimize machining hours. This keeps prototype costs competitive. Therefore, our customers typically save 20–30% compared to inefficient prototyping workflows.

Wide Material Options and Surface Finishes

Material choice directly impacts prototype test outcomes. We employ aluminum, steel, stainless steel, brass, copper, and engineering plastics such as POM, ABS, Nylon, and PEEK. In addition, surface finishes are applied to match the product’s functional and cosmetic requirements.

Rapid Prototyping Manufacturing Techniques at Sochain Precision

Our CNC Prototype Service integrates multiple manufacturing technologies so engineers can choose based on performance, cost, and lead time.

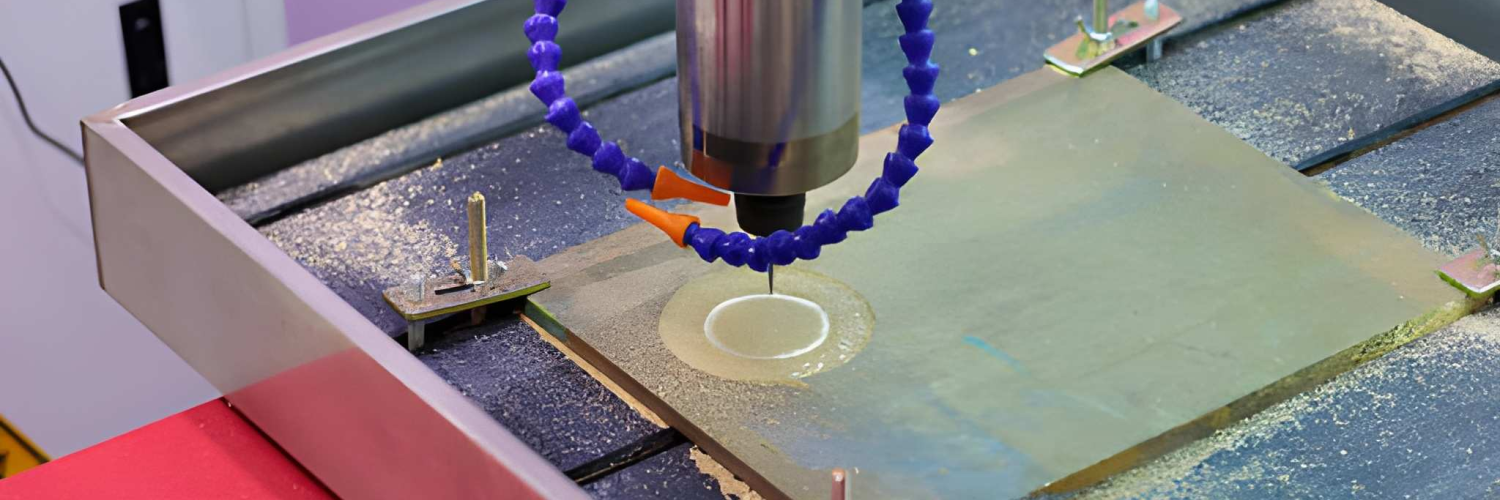

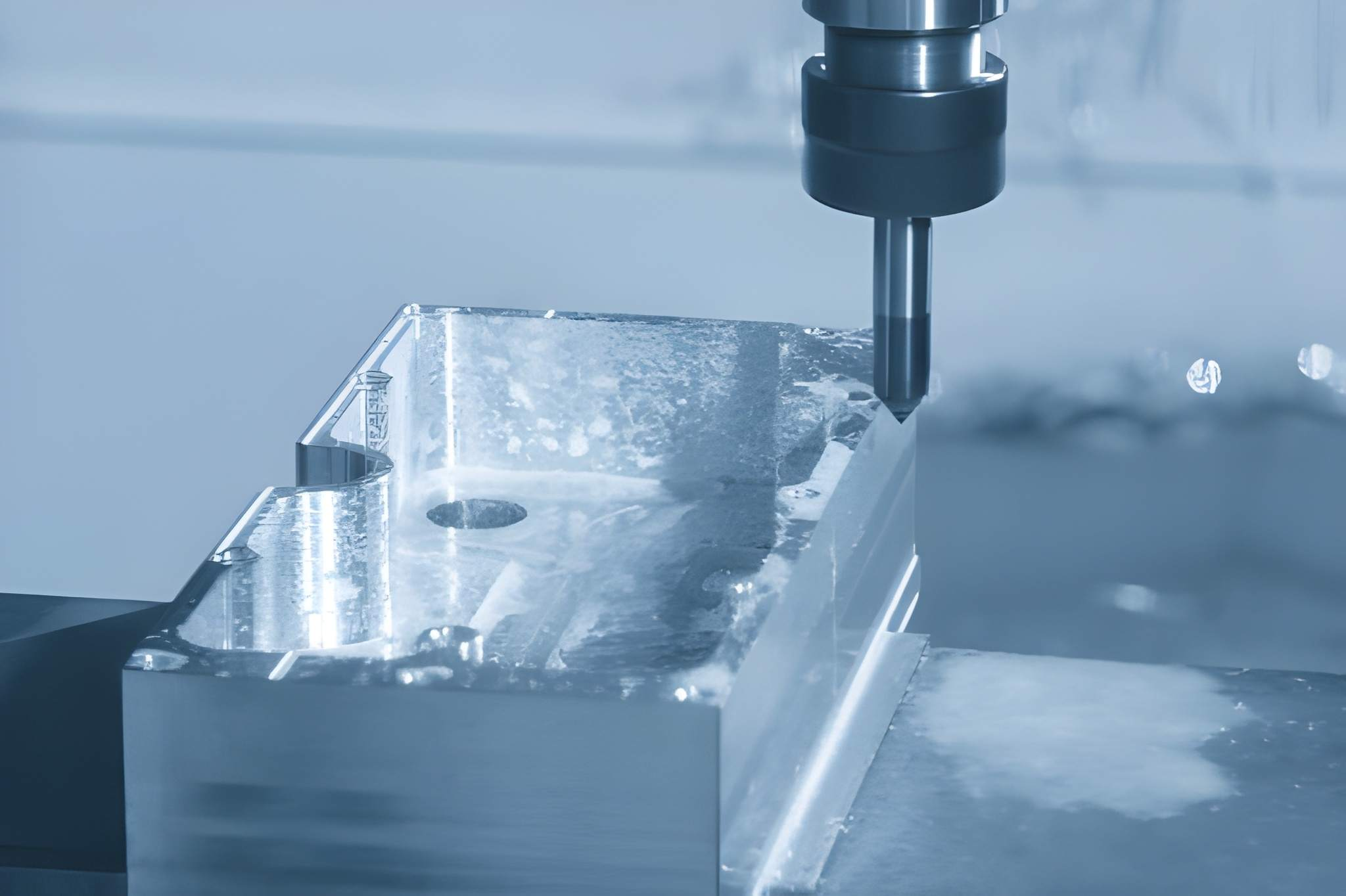

Rapid CNC Machining Prototype Service

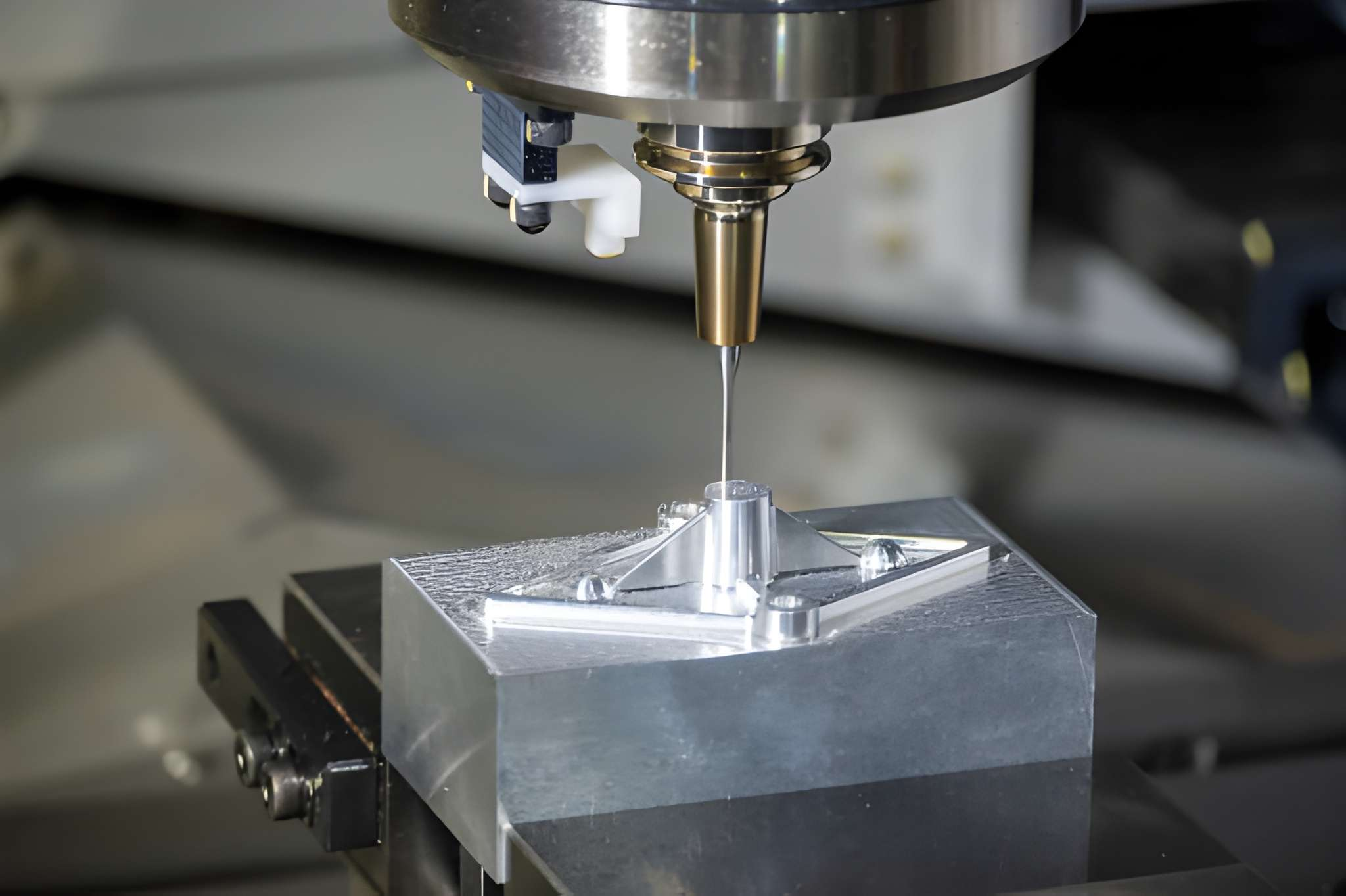

CNC machining is the most functionally accurate way to manufacture prototype parts. At Sochain Precision, we use 3-axis, 4-axis, and 5-axis CNC machines, which enable us to produce parts with complex geometries. Generally, the maximum size of parts that can be produced is 800 mm, depending on the material type. CNC machining is generally the best method of producing functional prototypes that require high mechanical strength and/or have very close tolerances.

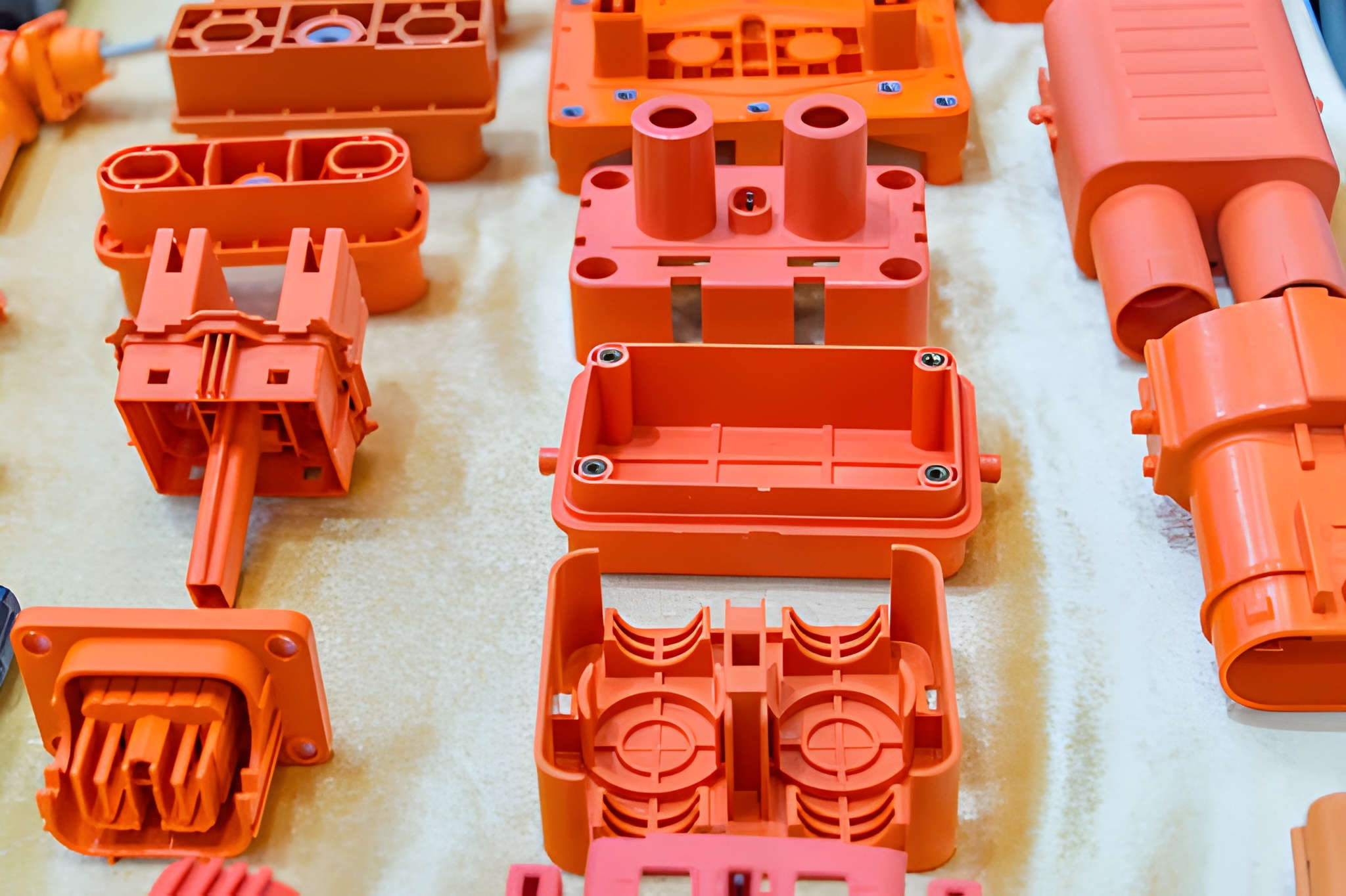

Rapid Injection Molding for Functional Prototypes

In the injection molding process, we use rapid tooling to produce prototypes in short runs and in bulk quantities. In general, the typical tolerances of injection molded parts remain under ±0.05 mm. This technique enables you to test the behavior of plastics and other materials before investing in the full mold development process.

Rapid Sheet Metal Fabrication Prototypes

Sheet metal fabrication supports the creation of metal prototypes for enclosures and structural parts. Our precision laser cutting and bending processes allow us to test and validate flat pattern designs, bend radii, and assembly alignments. The thicknesses of the sheet metal typically range from 0.5 mm to 6 mm.

Rapid Vacuum Casting for Small Batch Parts

Vacuum casting is the method of producing up to 20-50 parts per mold. It replicates surface appearance and consistency for short-run quantities. It is commonly used to create presentation samples and to test the functional properties of plastics.

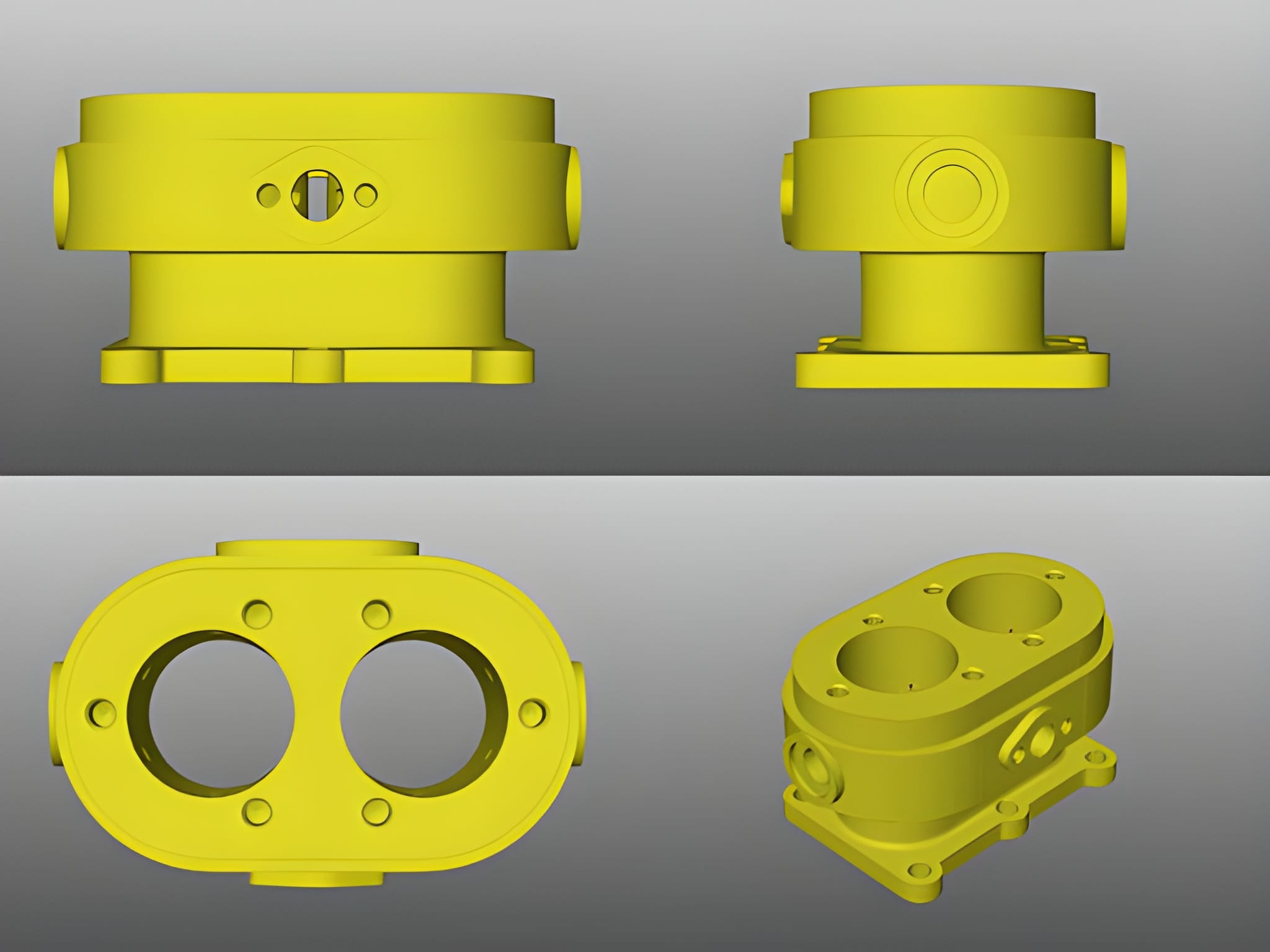

Die Casting Prototype Manufacturing

Die casting prototypes are also used to test early-stage dies and their ability to produce parts with the desired characteristics. Typically, the tolerances of die-cast parts are approximately ±0.1 mm and depend on the part geometry being produced.

By developing a solid prototype during the early stages of the development process, we can help minimize the number of tooling changes that need to occur before starting mass production.

From CNC Prototype Service to Full Manufacturing at Sochain Precision

When developing our machining strategies, selecting cutters, establishing datum references, and performing inspections on prototypes, we always plan to align those activities with our production methods.

We establish the same reference datum from prototype to production. From prototype to production, we lock down the hole location, mating faces, and functional features. Instead of rebuilding our tool paths, we refine them. Therefore, the prototype is not just a temporary part, but a foundational element of manufacturing. This approach avoids dimensional drift and tolerance mismatch when transitioning to higher production volumes.

Prototype Machining for Design Validation

When designing a prototype for design validation, we produce the part using production-quality materials and keeping tight tolerances. When producing prototypes for design validation, we create features such as thin-walled sections, deep cavities, and fine threads exactly as specified to identify potential problems earlier. Typical checks supported by prototypes include:

Stack-up of tolerances of multi-part assembliesVerification of press-fit and slip-fit shafts and boresEvaluation of thread engagement depth and strengthIdentifying deformation due to clamping or assembly loadChecking of heat-induced expansion on aluminum and plastic parts

Low-Volume Manufacturing for Market Testing

Low-volume manufacturing provides a bridge between engineering validation and commercial launch. In addition to using production-quality machining parameters, we produce parts that reflect the cost and performance of actual manufacturing. It is commonly used for;

Evaluating the durability of a product under repeated useTest the performance of multiple units of a product, rather than samplesIdentify tolerance sensitivities among different product batchesValidate the assembly time and product tool accessibility

Typically, low-volume manufacturing consists of 20 to 500 units per batch, depending on the geometry and product material.

Medium and Mass Production Support

When volumes increase, we focus on stability and repeatability. Fixtures are hardened; cutting tools are standardized; and process capability is measured and tracked. Critical dimensions are measured to detect any possible dimensional drift. Since the foundation was established during the prototyping phase, production scaling does not introduce any additional variables. Production Readiness Includes:

Optimization of machining sequences to minimize cycle timeMonitoring of cutting tool life to consistently achieve the required dimensionsApplication of statistical process control (SPC)to key features, if necessaryEstablishment of specific acceptance criteria for in-process inspectionIndustries We Serve With CNC Prototype Service at Sochain Precision

Different industries place unique stresses, tolerance, and lifespan expectations on the products they develop. Our CNC Prototype Service adjusts the machining strategy and inspection level according to these requirements.

Automotive Prototyping

Automotive prototypes must endure vibration, temperature fluctuations, and repeated assembly cycles. At Sochain Precision, we focus on verifying bracket alignment, mounting hole accuracy, and structural stiffness. Many automotive parts are subjected to load testing before they are approved.

Aerospace CNC Prototype Manufacturing

Aerospace prototypes require both high-dimensional accuracy and surface quality. We carefully monitor burrs, edge quality, and tool marks on aerospace parts. We support complex geometries with multi-axis machining. Key areas of focus include:

Optimizing lightweight structuresEnsuring flatness and parallelismMaintaining surface finish for stress testing

Medical Device Prototyping Solutions

Medical prototypes require high-dimensional accuracy and consistent surface quality. We carefully monitor sharp edges, surface defects, and dimensional variation on medical devices. We document the inspection records to facilitate validation. General medical requirements include:

Smooth surface finishes on contacting areasConsistency in dimensions of mating partsConsistency in dimensional repeatability among small batchesRobotics and Automation Equipment Parts

Robotics parts require highly accurate concentricity, parallelism, and bearing seat positioning. Any error in these areas can impact overall component system performance.

Industrial and Communication Equipment Parts

Industrial parts frequently contain combinations of tight and loose tolerances in a single part. We carefully manage data to achieve functional alignment without unnecessary cost.

New Energy and Consumer Products

These prototypes balance aesthetic appeal with functional requirements. Consistent surface finish, edge quality, and dimensional symmetry are essential for evaluation and presentation purposes.

CNC Prototype Service Tolerances and Standards at Sochain Precision

We apply tolerance standards based on the functional requirements of each part. Tighter tolerances add unnecessary cost without providing corresponding benefits. We work closely with customers to apply precision only when it impacts the performance of the part.

CNC Machining Tolerance Capabilities

Our CNC Prototype Service provides a wide range of tolerance capabilities, depending on the geometry and part material. Typical practical ranges:

General machining tolerance:±0.02 mmFunctional features:±0.01 mmCritical mating features:±0.005 mmPositional tolerance of holes:Controlled via datum strategyInjection Molded Part Accuracy

The primary purpose of injection-molded prototypes is to verify process repeatability and part consistency across multiple production cycles. Early in the process, we analyze the shrinkage behavior of the plastic. We also evaluate the wall thickness uniformity to determine the likelihood of warping.

Sheet Metal and 3D Printed Parts

Sheet metal prototypes are developed based on calculated bend allowances and controlled bend radii. We control flatness through process sequencing. 3D printed parts are solely used to validate geometry, not for evaluating tolerance-critical aspects.

Types of CNC Prototypes We Produce at Sochain Precision

Not every prototype works the same and is used for one purpose. Our CNC prototype service is also designed to meet the desired goals, depending on the intended part application.

Concept Models

The concept models are mainly created to verify geometry and layout. Concept models ensure that the overall size, fit, and basic assembly relations are accurate before designers actually start to state tight tolerances and expensive materials. We choose machining strategies that focus on efficiency and cost-effectiveness to keep external dimensions accurate but at the lowest cost possible. Examples of uses include:

Checking of enclosure clearances and mounting locationsEvaluating mating parts and fastener accessConsidering the ergonomics and exterior formEarly detection of apparent design conflictsWhere tolerances are within our reach, we loosen them. Surface finish and cosmetic quality are considered secondary. We do not want to give designers flawless cosmetics, but give feedback in time.

Functional Testing Prototypes

Functional prototypes are done to imitate quality parts of production. The materials used in their functional prototypes are the same as those that are expected in manufacturing. Controlled tolerances are provided on important features of the functional prototype. These models are made to undergo real testing, rather than visual examination. The common testing situations are:

Load test of brackets and framesRotating and sliding interfacesWear testingThread engagement and torque testsHeat and thermal expansion tests

Engineering and Pre-Production Prototypes

Engineering prototyping is done by a full production discipline. Datums are specified; inspection plans are made up; and surface treatments are in line with final needs. The engineering prototypes are used for:

Getting the approval of the customerCarrying out certification and compliance testingValidating assembly linesWe kill the wonder by working out prototypes that conform to the logic of production, and we find ourselves in the midst of unexpected difficulties in the passage over to low-volume and mass production.

CNC Prototype Service Workflow at Sochain Precision

Our workflow is not only intended to reduce the production speed and increases later rework. We work the opposite.

Send CAD Files and Get an Instant Quote

Geometry, tolerance callouts, and material selection are checked by our engineers when files are sent. The basis of quotes is actual machining time, set up, tooling requirements, and inspection effort. Before pricing is settled, unrealistic tolerances are indicated.

Design for Manufacturability Feedback

Before commencement of machining, we discuss areas of problems we frequently encounter, including:

- Big pockets, small end mills

- EDM is needed to cut sharp internal corners

- Walls are thin and easily vibrate

- Stricker tolerances than functional

Our recommendations will help you reduce the cost and be more repeatable without compromising performance. This move itself can save time and money for the customers.

Commencement of Precision CNC Prototype Manufacturing

Machining commences with a fixed datum. Sequencing of parts is done to regulate stress release and distortion. Multi-axis machining is applied in instances where it minimizes setups and enhances precision. The cutting parameters and tool wear are observed on the critical features.

Final Inspection and Fast Delivery

Where necessary, critical dimensions are measured with calibration instruments or CMMs. Manual checks are done on the quality of surfaces, edge conditions, and thread integrity. Components are produced, inspected, and delivered in alignment with development timelines.

Start Your CNC Prototype Service Today With Sochain Precision

Upload Files for Secure and Confidential Quoting: Your designs will be reviewed by experienced engineers, and after a complete review, we will give practical feedback to improve your design. We will start production only when the approach is clear and reliable.

FAQs

- What do I need to provide for a prototype quote?

Just share your CAD files, material choice, tolerances, and quantity. This helps us give an accurate quote and plan the machining process efficiently.

2. Can you make prototypes with thin walls or complex shapes?

Yes, we check your design first and suggest the right toolpaths and fixturing to avoid vibration or part distortion.

3. Will I get feedback on my design before machining?

Yes, our team provides practical suggestions to improve manufacturability, reduce risks, and ensure your prototype performs as intended.

4. Can I change the material after the first prototype?

Yes, you can test the first prototype and switch materials if needed. This helps you find the best option before full production.

5. What is the maximum part size for CNC prototypes?

Most parts can be machined up to 800 mm, depending on material and design. Complex geometries may require special setups.

6. Do you provide inspection reports with prototypes?

Yes, you can request CMM or precision gauge reports showing dimensional checks and critical features to confirm quality.

Start Manufacturing Your Custom Parts Now!

Understanding Your Goals, Delivering Your Solutions – We’re Committed to Making CNC Machining Simple and Stress-Free!