CNC Lathe Components Manufacturing Service

We manufacture CNC lathe components built for real mechanical use.

These parts are not cosmetic. They control rotation, alignment, load transfer, and wear.

Our CNC turning process focuses on dimensional stability, surface quality, and repeatable results across every production batch.

Rapid prototyping and full-scale production

ISO accredited & QC checks

All in-house processes

Used in over 50 countries

FREE Instant quotations

Precision CNC Lathe Components for Mechanical Assemblies

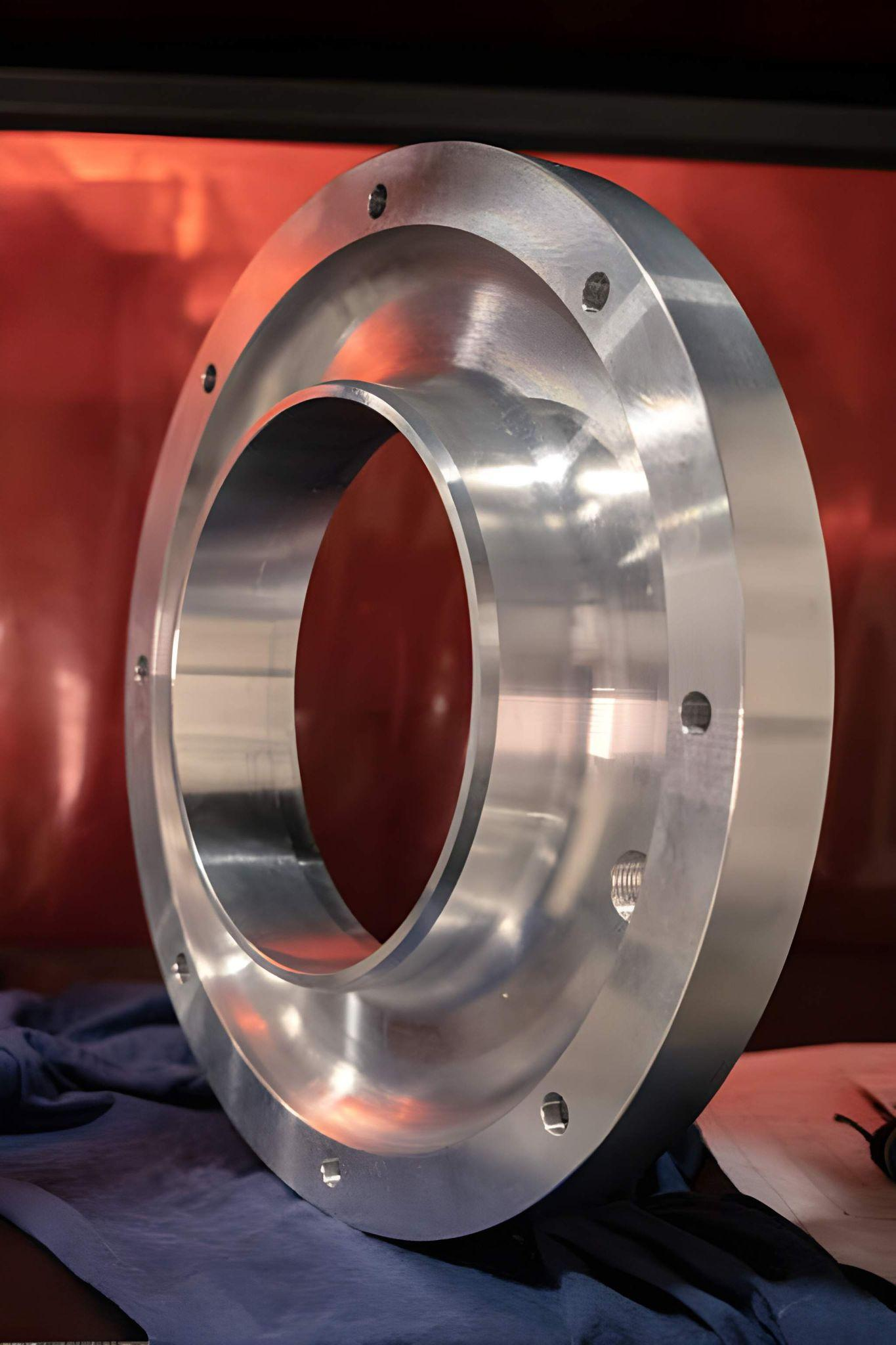

CNC lathe components include bearings, seals, bushings, threads, and housings. A small dimensional error can result in vibration, wear, or assembly failure. That is the reason why we pay attention to geometry control rather than appearance.

At Sochain Precision, we employ controlled cutting parameters to maintain accurate diameter, shoulder, taper, and groove. This also keeps roundness and concentricity to a limit. Whenever feasible, critical features are machined in the same setup. This minimizes the positional error and enhances component fit. As a result, parts fit in place and carry out dependably during final usage.

Our CNC Turning Capabilities for Complex Lathe Components

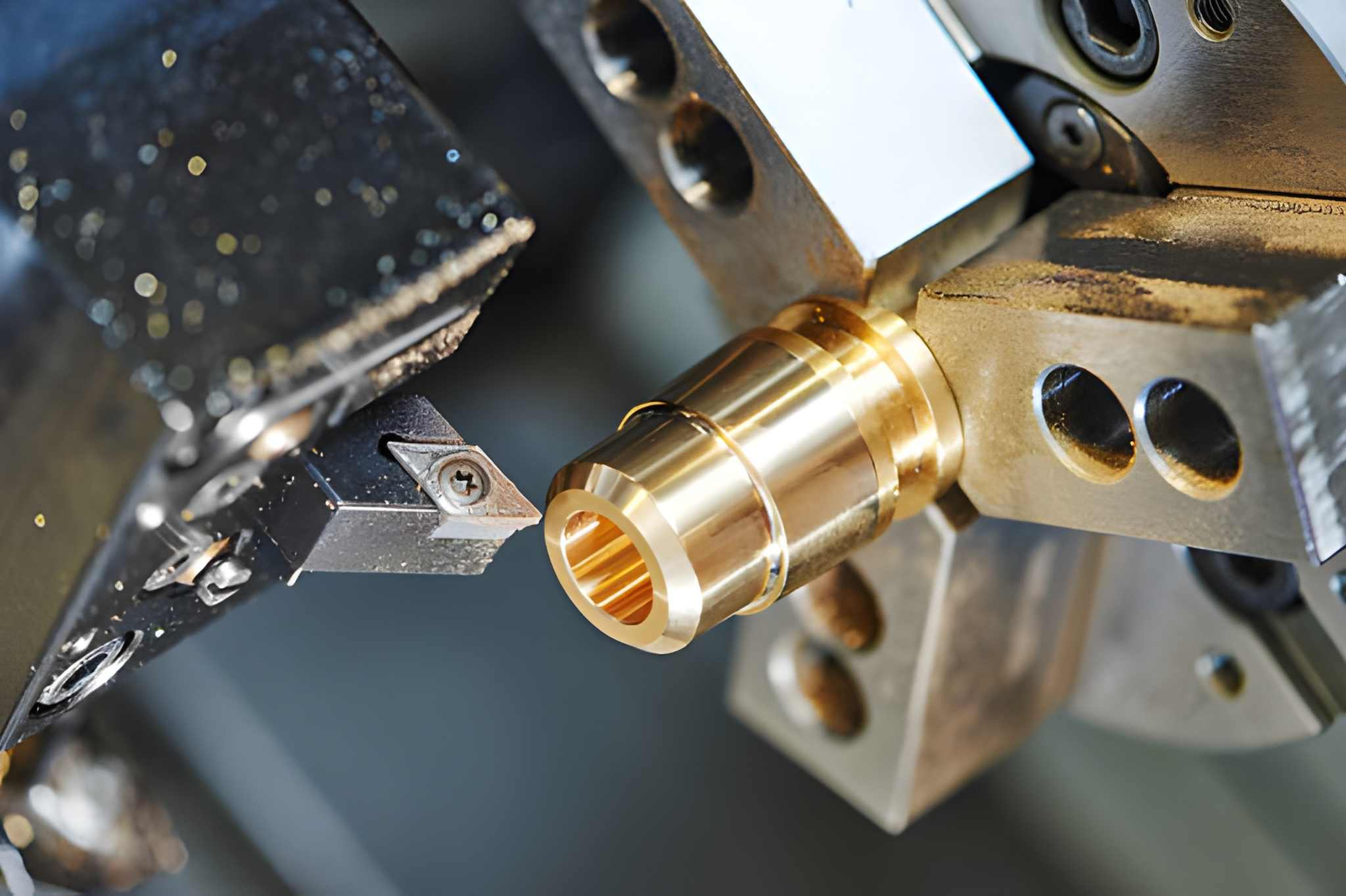

Our advanced CNC lathe machines handle both simple and complicated turned parts. We machine everything from straight shafts to multi-feature components. Here are some of the common machining operations we perform at our factory.

Standard CNC Turning

We do facing, straight turning, taper turning, grooving, internal turning, and outside threading. These are used in supporting shafts, sleeves, Bushings, and threaded housings. The optimal cutting strategies depend on the material hardness, the ability to control a chip, and the surface finish requirements.

Multi-Axis CNC Turning with Live Tooling

Live tooling is used to machine features such as flats, cross-holes, and slots without excessive material removal from the part. This improves alignment between turned and milled features. It also minimizes handling and setup variation.

Swiss-Type CNC Lathe Components

Swiss CNC turning helps in holding long or small-diameter components near the cutting zone. This prevents deflection and increases straightness. It is best suited to the precision pins, medical components, and tiny mechanical components.

CNC Lathe Components We Manufacture at Sochain Precision

Our CNC lathe components/parts are manufactured according to their functionality, not standard catalogs. Here are the common products we produce daily.

Shafts and Rotational Components

The shafts are machined at regulated surface finishes and diameters. This provides an easy rotation and desired bearing fit. We control runout, shoulder square, and surface consistency.

Bushings, Sleeves, and Spacers

These components require accurate internal and external diameters. We define wall thickness and roundness based on the fit type: press, slip, or interference. Parts are manufactured depending on the application needs.

Threaded Lathe Components

The threads are cut considering the pitch accuracy and the flank quality. The internal and external threads are tested to run smoothly. This avoids galling, binding, and assembly fit.

Custom CNC Turned Parts

We also make custom parts right off the metal sheets. Tolerances are checked in terms of practicability, and in cases of necessity, we propose modifications leading to high machinability or long life of parts.

Materials for CNC Lathe Components

The choice of material influences machining behavior, wear, and service life. Therefore, we are very careful and provide our customers number of material options to choose from. For example;

Metal Materials

- Aluminum 6061

- Aluminum 7075

- Stainless Steel 304

- Stainless Steel 316

- Stainless Steel 17-4 PH

- Carbon Steel 1018

- Carbon Steel 1045

- Alloy Steel 4140

- Brass C360

- Brass C260

- Titanium Grade 2

- Titanium Grade 5

Engineering Plastics

- POM (Delrin / Acetal)

- Nylon PA6

- Nylon PA66

- PTFE (Teflon)

- PEEK

- UHMW-PE

- PVC

- PMMA (Acrylic)

- ABS

Applications of CNC Lathe Components

CNC lathe components have widespread use across various sectors, such as aerospace, automotive, electronics, and energy.

Automotive Components

We turn shafts, spacers, bushings, and pins that are engine, gearbox, and suspension parts. These sections should remain circular and concentric to prevent rotational vibration during rotation. Fixtures are clamped together to ensure that bearings are pressed without play. The finish is regulated to have low friction and early wear during continuous movement.

Industrial Machinery

Turned parts, e.g., rollers, sleeves, hubs, and couplings, are used in industrial machines. These parts are loaded and work over extensive periods. We also emphasize straightness and runout, hence parts rotate at a smooth speed. Edges are cut so that they are not damaged when assembling and maintaining.

Medical and Precision Equipment

Tiny parts require high precision and fixation. These are usually used in medical and lab equipment. We machine spacers, threaded connectors, and housings that should fit freely. It has smooth finishes, making parts easy to clean and not to trap debris. Checks are made on dimensions to guarantee the repeatability of assembly.

Electronics and Hardware Assemblies

Consumer electronics use minute components of lathes, such as standoffs, inserts, and pins. These components have to thread easily and have to fit square in assembly. The thread form and diameter are adjusted to ensure a proper fastener seat. Components are maintained in the same way so that it does not crack plastics or cause strain in the circuit boards.

CNC Lathe Components Tolerances & Dimensional Control

CNC lathe parts do not merely fit into the assemblies, but must be the correct sizes. Normal features are maintained at constant machining tolerances. Tighter control is applied to critical fits like bearing seats, sealing surfaces, and alignment features. The critical dimensions are all measured using calibrated inspection instruments.

Roundness, concentricity, and surface finish are regulated in the machining process. We do not rely on post-processing to correct mistakes. This approach improves part stability and supports long-term sustainability.

Surface Finishing Options for CNC Lathe Components

As-Machined

Components are passed directly from the CNC lathe machine. However, there can be visible light tool marks. This finish is suitable for internal components, fixtures, and parts, in which functionality is more crucial than cosmetics.

Deburring and Edge Rounding

All sharp edges are removed to make the parts safe to handle. The edges are made mildly rounded, and to facilitate assembly, to avoid stress points. Slots and threads are wiped off so that fasteners fit perfectly.

Fine Polishing

The polishing purpose is to have a smoother contact part surface. It reduces the friction and improves movement among the parts that mate. This is typical in shafts, bushings, and sealing faces.

Mirror Polishing

Mirror polishing finish produces a bright reflective finish. It is applied to visible parts or components, which need extremely low friction. Tolerances are regulated to prevent a change in size during polishing.

Bead Blasting

The bead blasting finish creates a clean and smooth surface. It eliminates small machining marks without affecting part dimensions. It is preferred for applications that require a consistent cosmetic finish or surface preparation before coating.

Brushing

When brushed, the surface develops a straight, uniform grain. It enhances the looks and conceals light handling stains, and is primarily used on stainless steel and aluminum components.

Anodizing

Anodizing is limited to aluminum parts. It increases resistance to corrosion and surface hardness. Both protection and appearance can be achieved by clear and colored anodizing.

Hard Anodizing

Parts that are subjected to wear are hard anodized. It forms an overlay of a thick, durable surface. It is typically used in high-utilization and sliding components.

Plating

Metal plating provides the surface with a thin film of protection. Nickel plating enhances wear and corrosion resistance. While steel components are commonly protected by Zinc plating.

Black Oxide

Black oxide offers moderate levels of corrosion resistance and a clean black look. It does not alter part sizes and is applicable for steel components, which can also be finished uniformly.

Passivation

Generally, the stainless steel parts are passivated. It eliminates the surface contaminants and enhances the corrosion resistance. The finish of the base material is not changed.

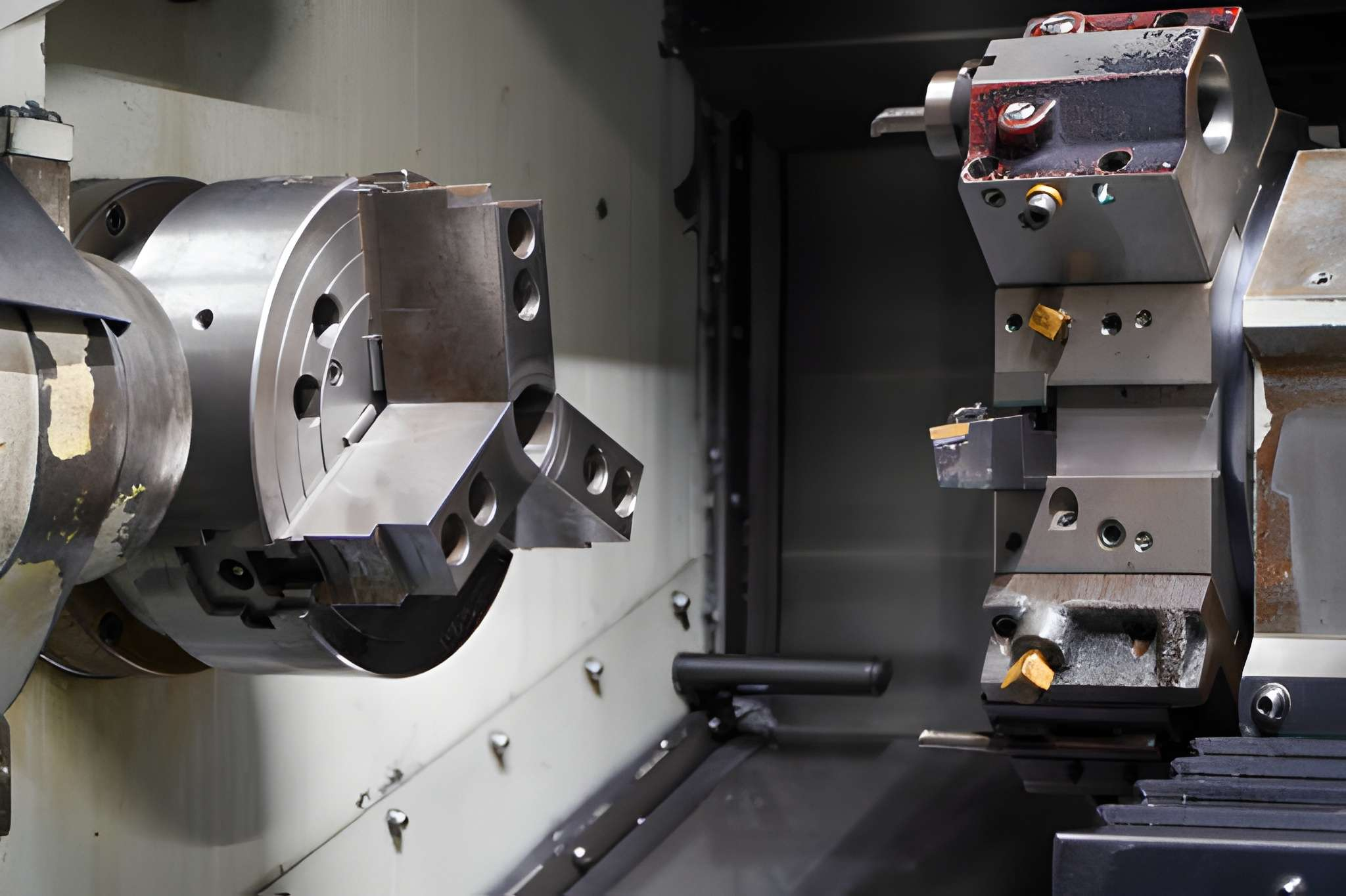

Our Lathe Components Machining Workflow

Design Review and Feasibility Check

We inspect the drawings to verify tolerances, material grade, and critical features. Early inspection of thread specifications, surface finishes, and concentricity points is done to prevent rework.

CAM Programming and Toolpath Planning

CAM softwares are used to program parts and control feeds, speeds, and tool engagement. The toolpaths are optimized to minimize chatter, heat, and tool wear. Passes related to roughing and finishing are separated to ensure dimensional stability.

CNC Turning and Machining Setup

Stable fixtures or collets are used to hold pieces of work in place to reduce runout. The tool offsets are configured and checked before manufacturing. The machining process is performed under controlled conditions so that the results are consistent throughout the part manufacturing.

In-Process Monitoring and Control

During machining, critical dimensions are checked to identify variation at an early stage. The wear of tools is checked, and they are substituted as required. The process is modified to ensure that the diameter is accurate and the surface is desirable.

Final Inspection and Quality Verification

Complete components undergo inspection in terms of size, surface finish, and thread accuracy. Measurements are taken to confirm that all parts meet the drawings. Packing and shipment are done only after verification.

Why Choose Us for CNC Lathe Components

We focus on functional machining, not generic output. Our team understands how turned parts behave in real-time assemblies. We support both prototypes and production runs. Lead times stay short without compromising inspection and process control.

FAQs

- What tolerances can CNC lathe components hold?

Most CNC lathe components are machined within ±0.01 mm. For features like shafts, bores, and mating diameters, tighter control up to ±0.005 mm is possible when the design allows it.

2. Are CNC lathe components used as finished parts?

Yes. CNC lathe components are often final-use parts. They are installed directly into assemblies without extra processing in automotive, industrial, and equipment applications.

3. Which materials work best for CNC lathe machining?

CNC lathes machine aluminum, steel, stainless steel, brass, copper, titanium, and selected engineering plastics. Each material is chosen based on strength, wear, heat, and operating conditions.

4. What CAD files are needed to start machining?

We work with STEP and IGES files. These formats keep dimensions accurate and help avoid errors during programming and machining.

5. How fast can CNC lathe parts be produced?

Simple parts are usually completed within 5 to 7 days. Complex geometries or higher quantities may need more time for setup and inspection.

6. Can CNC lathes cut threads and precision fits?

Yes. CNC turning is ideal for threads, grooves, shoulders, and tight-fit diameters. These features are machined in one setup to maintain alignment and accuracy.

Start Manufacturing Your Custom Parts Now!

Understanding Your Goals, Delivering Your Solutions – We’re Committed to Making CNC Machining Simple and Stress-Free!