Custom CNC Machining Solutions from China

Producing your custom CNC parts to exact specifications, delivered on schedule, and at highly competitive factory pricing.

- More Than 40 Verified Materials

- Custom Surface Treatments

- No MOQ Required

- Quick Lead Times Guaranteed

Save 30% on average!

15+Years

CNC Expertise

500+Customers

Globally

1M+

Custom Machined Parts

99.9%

Customer Satisfaction

Precision CNC Machining Services Provider in China

Are you seeking a trusted partner for CNC machining solutions?

Sochain Precision is a premier CNC machining services provider based in China.

Our advanced 3-axis, 4-axis, and 5-axis CNC milling machines, turning centers, and CNC lathes allow us to produce accurate, high-quality parts tailored to your specific needs.

With more than 50 CNC machines operating in our facility, Sochain Precision is your reliable partner for custom and high-precision CNC machining—no matter your industry.

CNC Milling

3 Axis, 4 Axis, and 5 Axis CNC Machining Solutions for both straightforward and intricate part geometries.

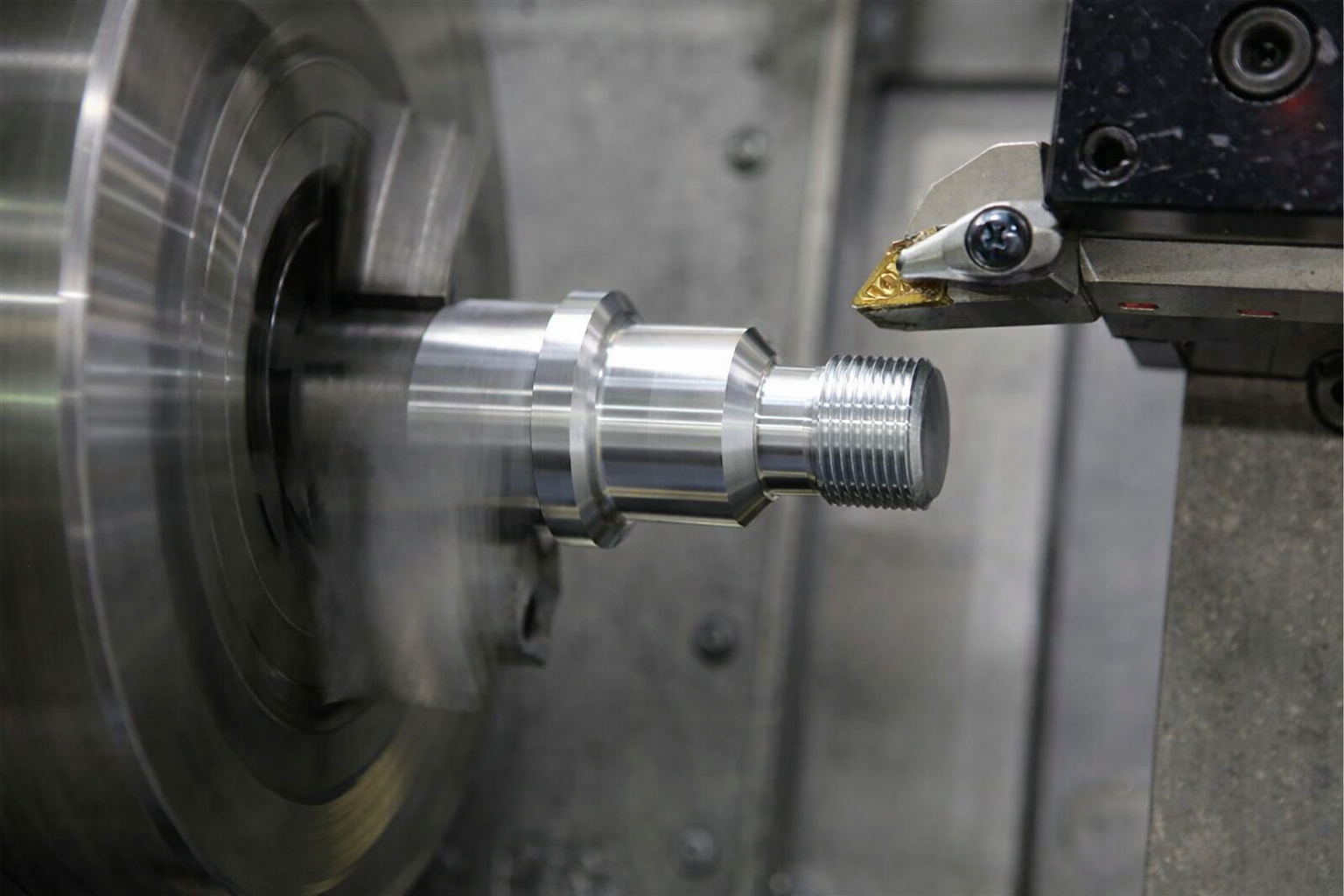

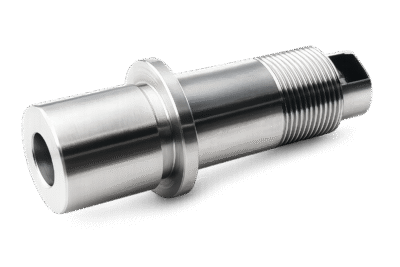

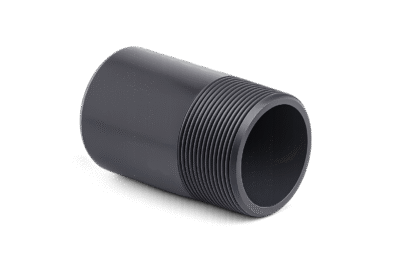

CNC Turning

CNC turning with live tooling integrates milling and lathe functions to produce parts with complex cylindrical and axial features.

Surface Finishes

Apply various surface treatments to your parts, including Anodizing, Sandblasting, Powder Coating, Plating, and more.

Materials for CNC Machined Components

Sochain provides an extensive selection of materials for custom CNC machining—both plastics and metals—covering, but not limited to, the following:

CNC Metals

Aluminum: Known for its excellent strength-to-weight ratio, cost-effectiveness, and recyclability, aluminum is a top choice across numerous industries.

Available Alloys: 6061-T6, 7075-T6, 2024, 5052, 6060, 5083, 2017, 6082

Surface Finishing Options: Alodine, Type II & III Anodizing, Hard Anodizing with PTFE, Electroless Nickel Plating (ENP), Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing

Stainless Steel: With excellent corrosion resistance and ductility, stainless steel is perfect for outdoor applications and easily formed into complex shapes.

Available Alloys: SS303, 304/304L, 316/316L, 17-4PH, 416, and more

Finishing Options: As Machined, Bead Blasting, Polishing, Decorative Chrome Plating, Powder Coating, Nickel Plating, Gold Plating, Silver Plating

Alloy Steel: Engineered by combining steel with elements such as manganese, nickel, and chromium, alloy steel offers enhanced strength, hardness, corrosion resistance, and longevity for specialized applications.

Available Alloys: AISI 1215, AISI 4140, AISI 4340, AISI 8620, AISI 4130

Finishing Options: Polishing, Plating, Painting, Powder Coating, and more

Tool Steel: Designed for manufacturing cutting tools, dies, and molds, tool steel is a high-carbon, high-alloy material known for its exceptional hardness, wear resistance, and toughness—ideal for demanding applications involving repeated stress or impact.

Available Alloys: A2, D2, O1, S7, M2 Tool Steel

Finishing Options: Bead or Sand Blasting, Polishing, Plating, Painting, Powder Coating, Heat Treatment, and more

Brass: Brass, a copper-zinc alloy with over 20% zinc content, is one of the most widely used materials in CNC machining due to its excellent machinability and versatility.

Available Alloys: C360, C260

Finishing Options: Nickel Plating, Bead Blasting, Gold Plating, Silver Plating

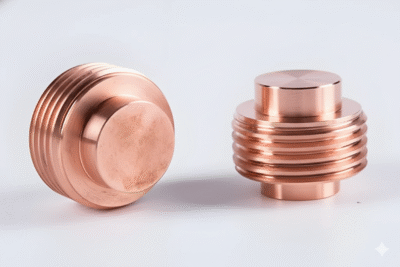

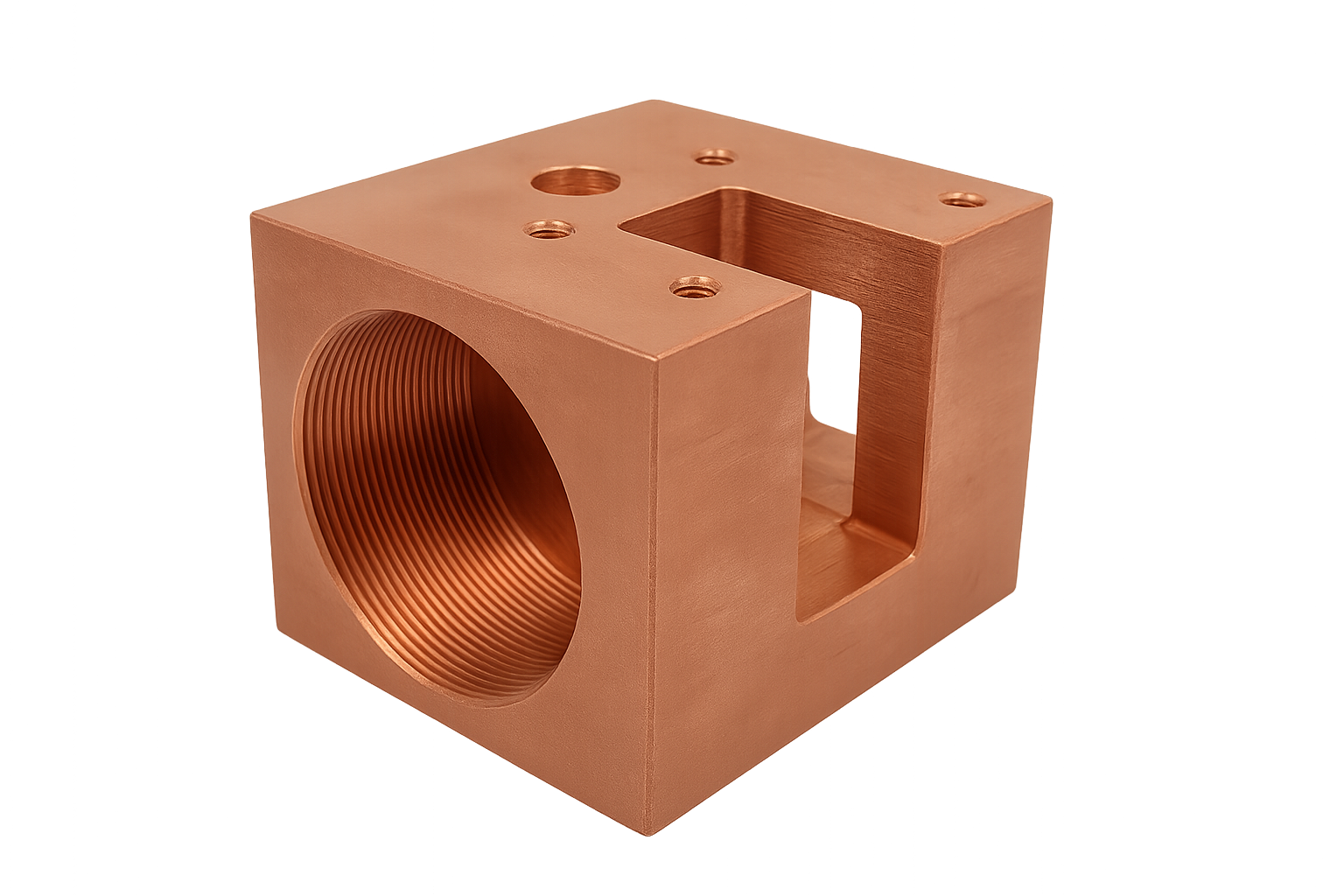

Copper: Known for its outstanding thermal and electrical conductivity, copper is a highly malleable and ductile metal widely used across various industrial applications.

Available Grades: C10100, C11000, C12200, C14500, C17200

Finishing Options: Plating, Polishin

Titanium: With its exceptional strength-to-weight ratio and low density, titanium is perfect for high-performance applications in aerospace, automotive, and medical fields. It also offers excellent corrosion resistance and endures harsh chemical environments.

Available Alloys: Ti-6Al-4V, Ti-6Al-2Sn-4Zr-2Mo, Ti-3Al-2.5V

Finishing Options: Polishing, Anodizing, Sandblasting, Chemical Etching, Laser Engraving, and more

Magnesium: Magnesium is a lightweight, silvery-white metal renowned for its outstanding strength-to-weight ratio, superior thermal and electrical conductivity, and broad applications across aerospace, automotive, and medical industries.

Available Alloys: AZ31B, AZ91D, We43, AM60B, ZK60A, QE22

Finishing Options: Blasting, Anodizing, Chromate Conversion Coating, Passivation, Powder Coating, Electroplating, and more

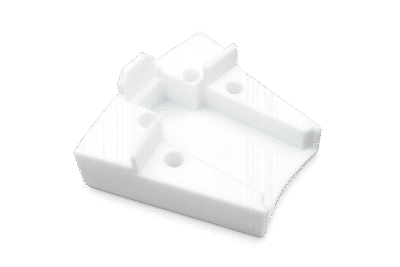

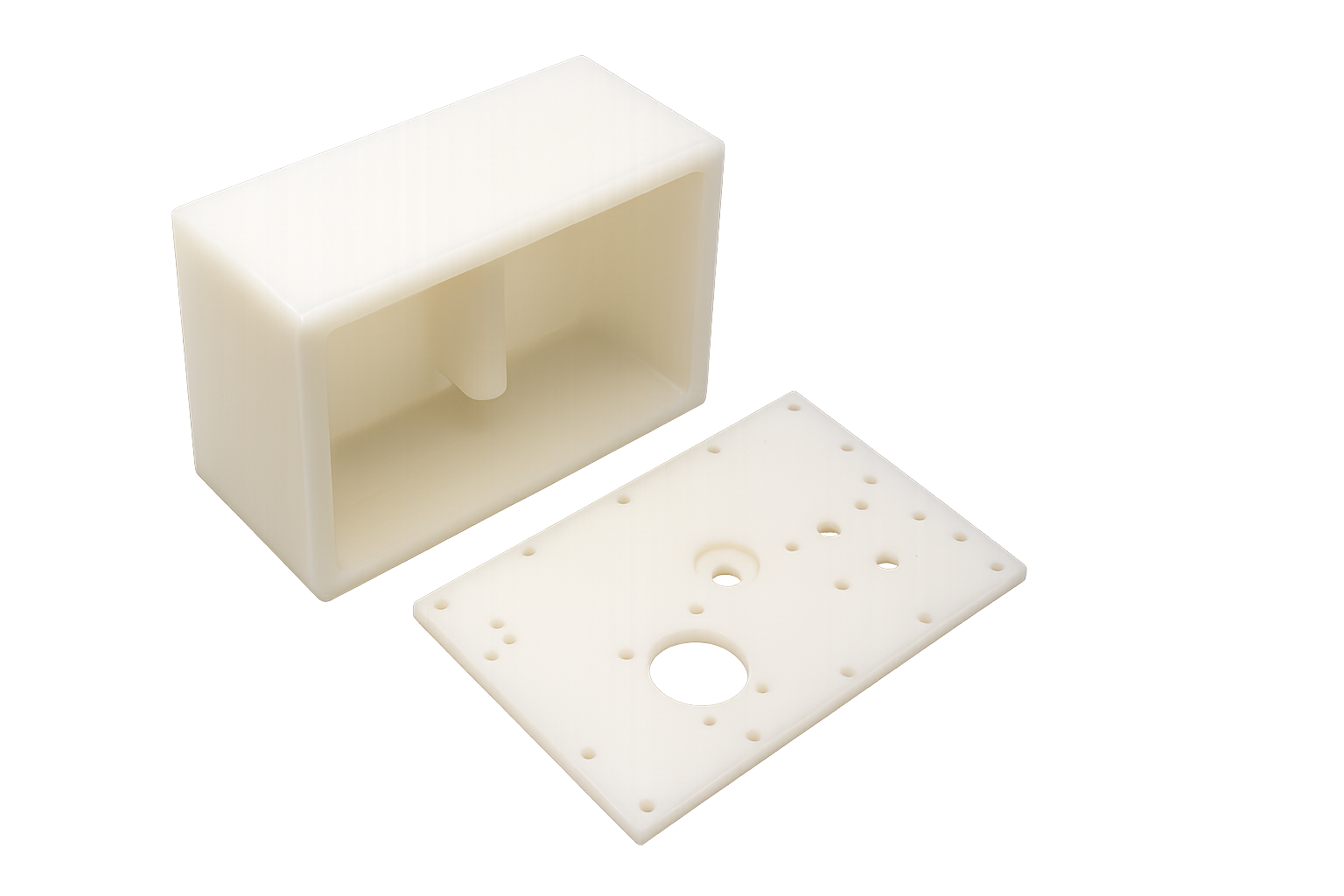

CNC Plastics

POM (Delrin/Acetal): Offers excellent stiffness, low friction, strong wear resistance, and good moisture resistance, making it easy to machine and ideal for precision parts.

Available Colors: White, Black, Brown

Available Grades: POM-C, POM-H, UV-Stabilized POM, Food-Grade POM

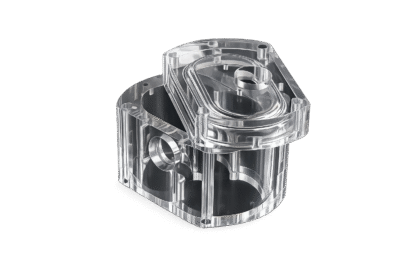

PMMA: Commonly referred to as “acrylic” or “plexiglass,” PMMA is a lightweight, impact-resistant material often used as a glass alternative in products like skylights, signage, displays, and optical lenses.

Available Color: Transparent

Available Grades: Extruded PMMA, Cast PMMA, Impact-Modified PMMA, UV-Stabilized PMMA, Heat-Resistant PMMA

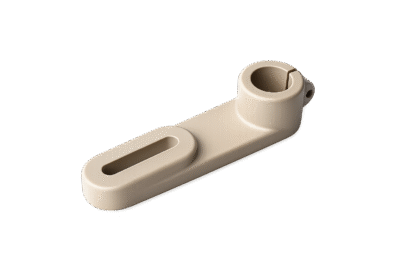

PEEK: Short for Polyether Ether Ketone, PEEK is a high-performance engineering plastic known for its outstanding mechanical strength, chemical resistance, and thermal stability.

Available Color: Beige, non-transparent

Available Grades: Unfilled PEEK, 30% Glass-Fiber Reinforced PEEK, 30% Carbon-Fiber Reinforced PEEK, Bearing Grade PEEK

ABS: Known for its toughness, rigidity, and lightweight properties, ABS is ideal for automotive components, electronic enclosures, toys, and everyday consumer products. It offers strong resistance to impact, chemicals, and heat, making it suitable for demanding environments.

Available Colors: Naturally opaque; available in black, white, gray, and other custom colors

Available Grades: General Purpose ABS, Flame Retardant ABS, High Impact ABS, Heat-Resistant ABS

Nylon: Nylon is a tough, flexible, and long-lasting material widely used in textiles and industrial components. Its excellent resistance to wear, chemicals, and moisture makes it ideal for applications like gears, bearings, and automotive parts.

Available Color: Typically found in its natural off-white or pale yellow shade

Available Grades: Nylon 6, Nylon 6/6, Nylon 11, Nylon 12

PTFE: PTFE (Teflon) is a premium engineering plastic recognized for its outstanding chemical resistance, extremely low friction, and excellent performance under high temperatures.

Available Color: Typically available in white or off-white shades

PVC: PVC, or polyvinyl chloride, is a durable thermoplastic polymer widely used across multiple industries. It offers excellent versatility and can be manufactured in both rigid and flexible forms.

Available Color: Clear or opaque

Available Grades: UPVC, PPVC, CPVC

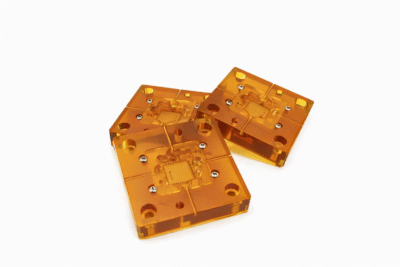

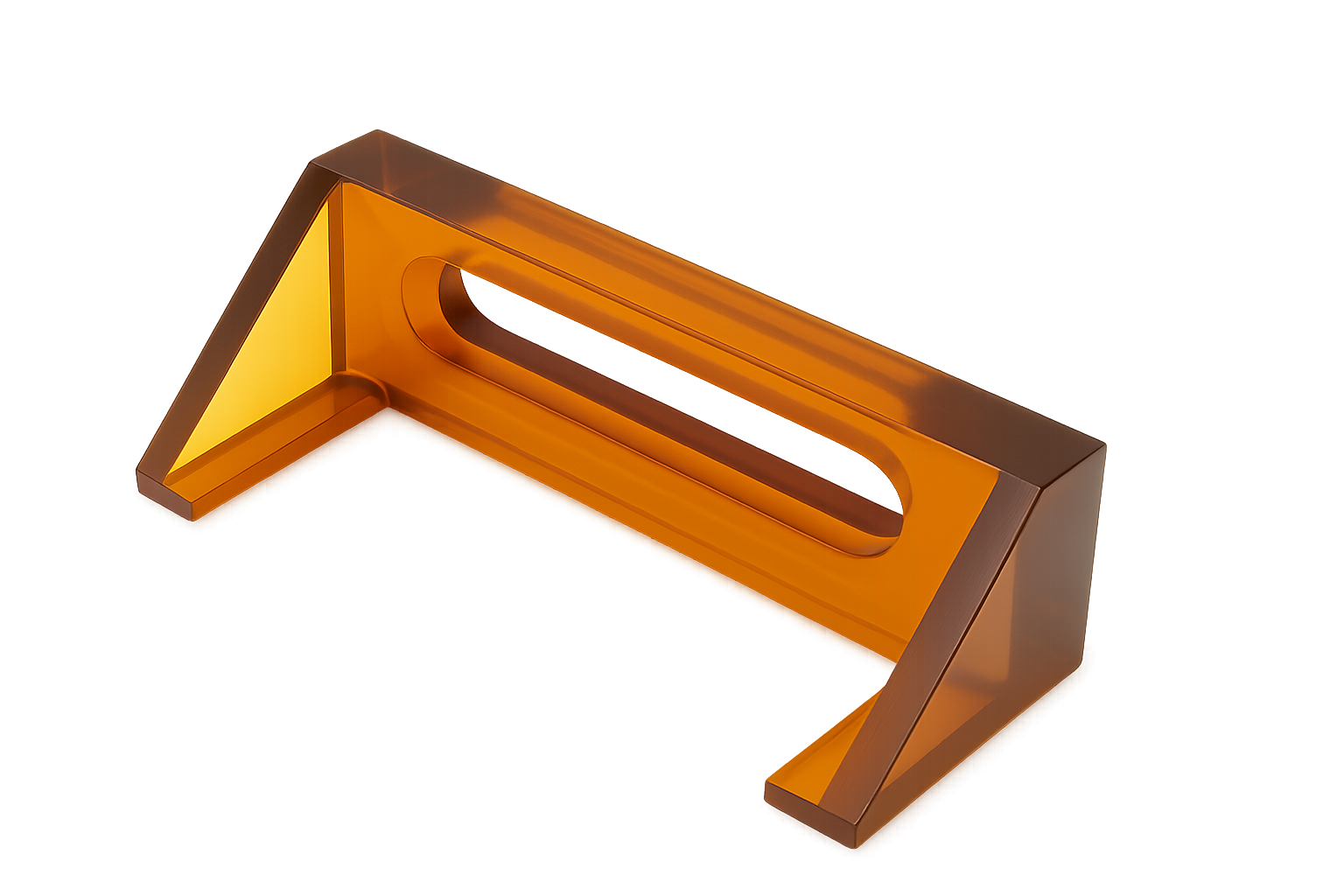

PEI: PEI is a high-performance thermoplastic offering superior mechanical strength, thermal stability, electrical insulation, and chemical resistance.

Available Color: Amber or brownish hue

Available Grades: Unfilled PEI, Glass-Filled PEI, Carbon-Filled PEI, Ultem PEI

PAI: Also known as Torlon Polyamide-imide, PAI is a high-performance thermoplastic renowned for its outstanding mechanical strength, which it retains across a broad temperature range.

Available Color: Yellow

Available Grades: Torlon 4203, Torlon 4503, Torlon 4301, Torlon 4501

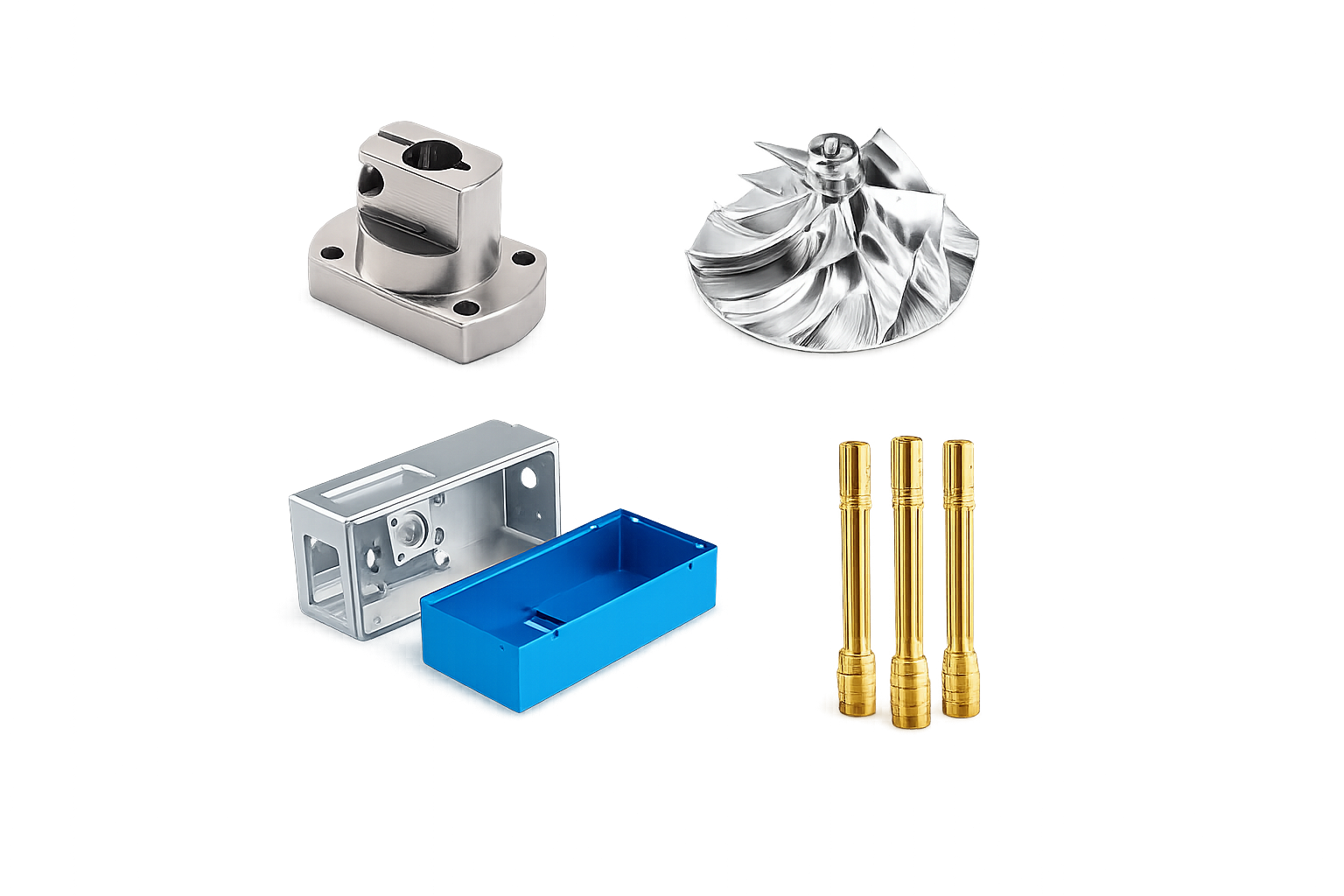

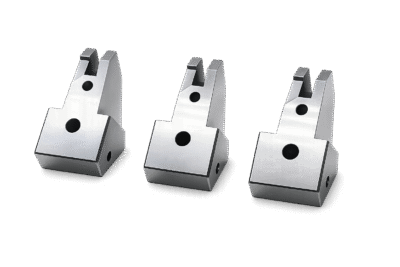

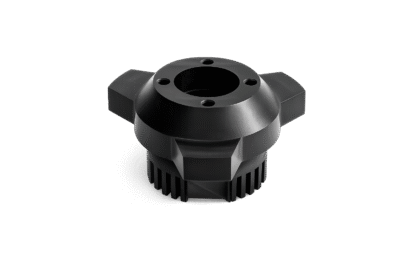

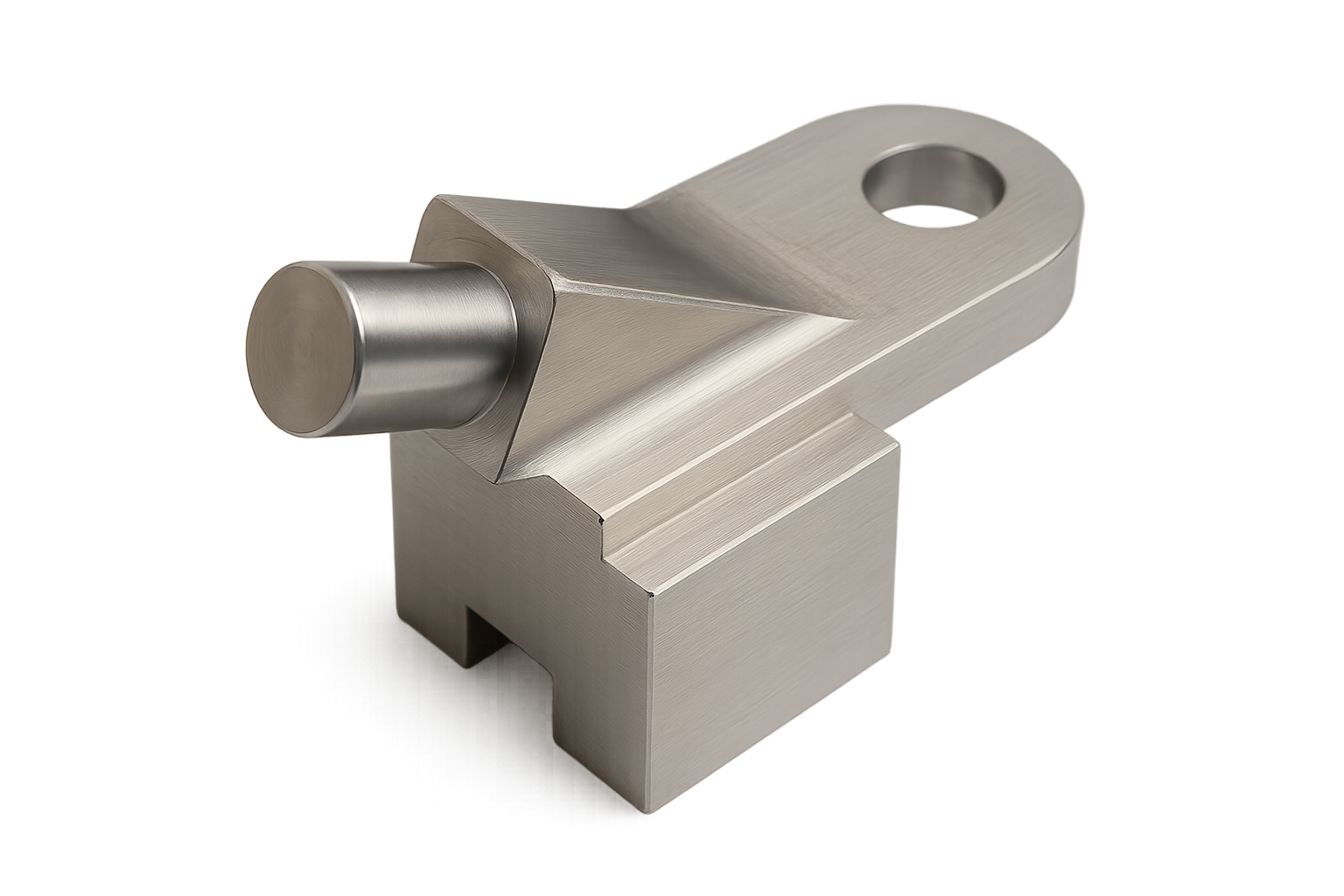

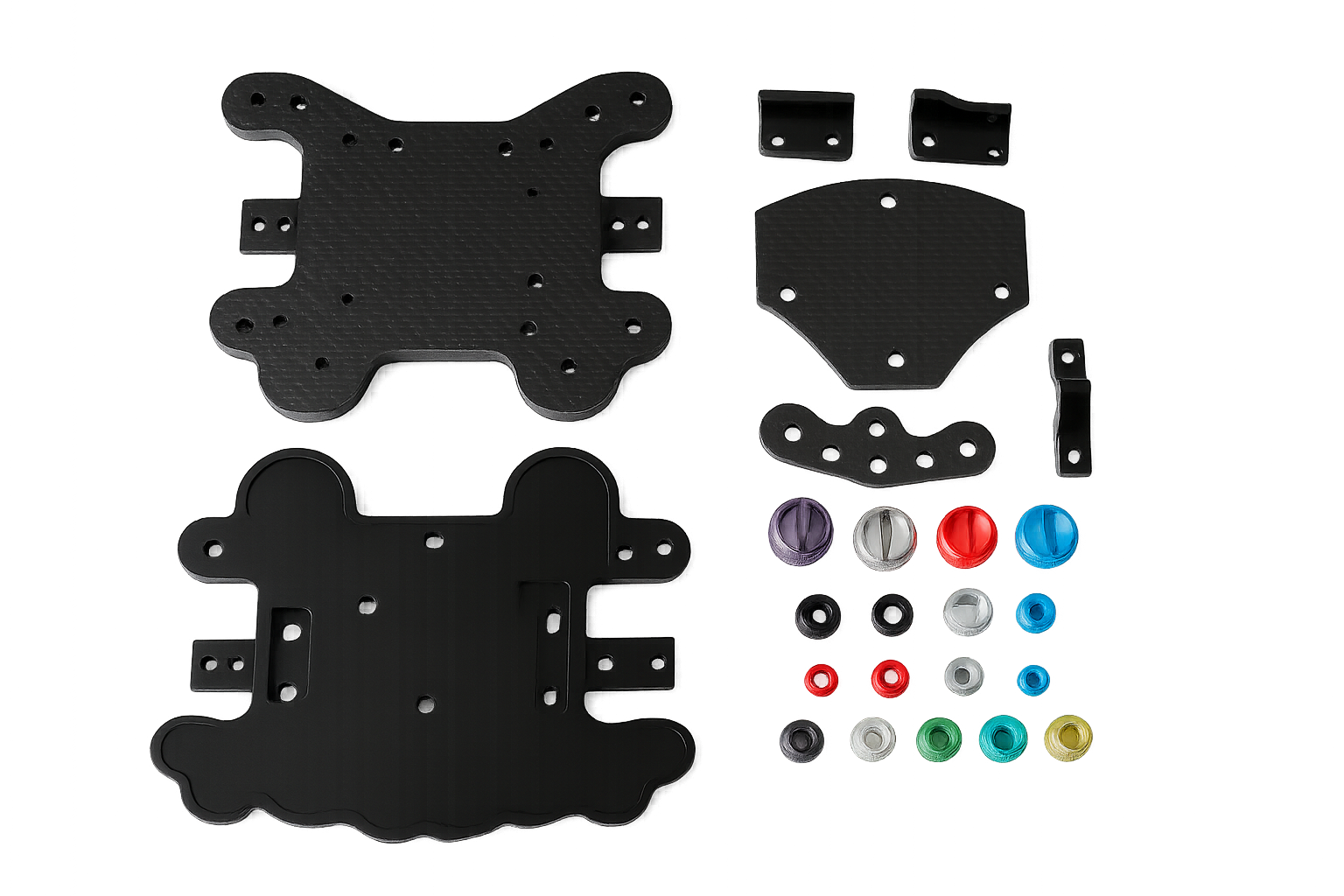

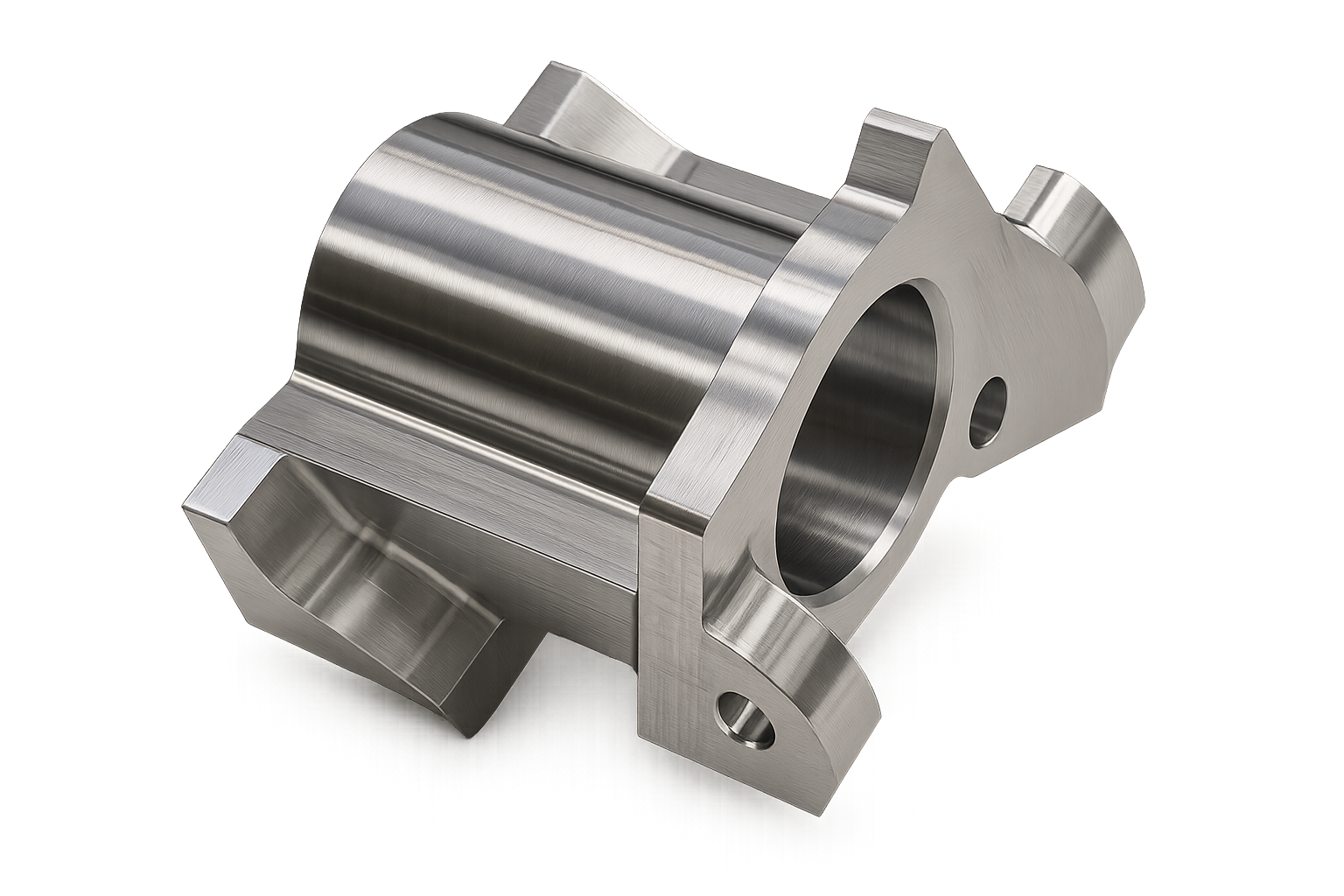

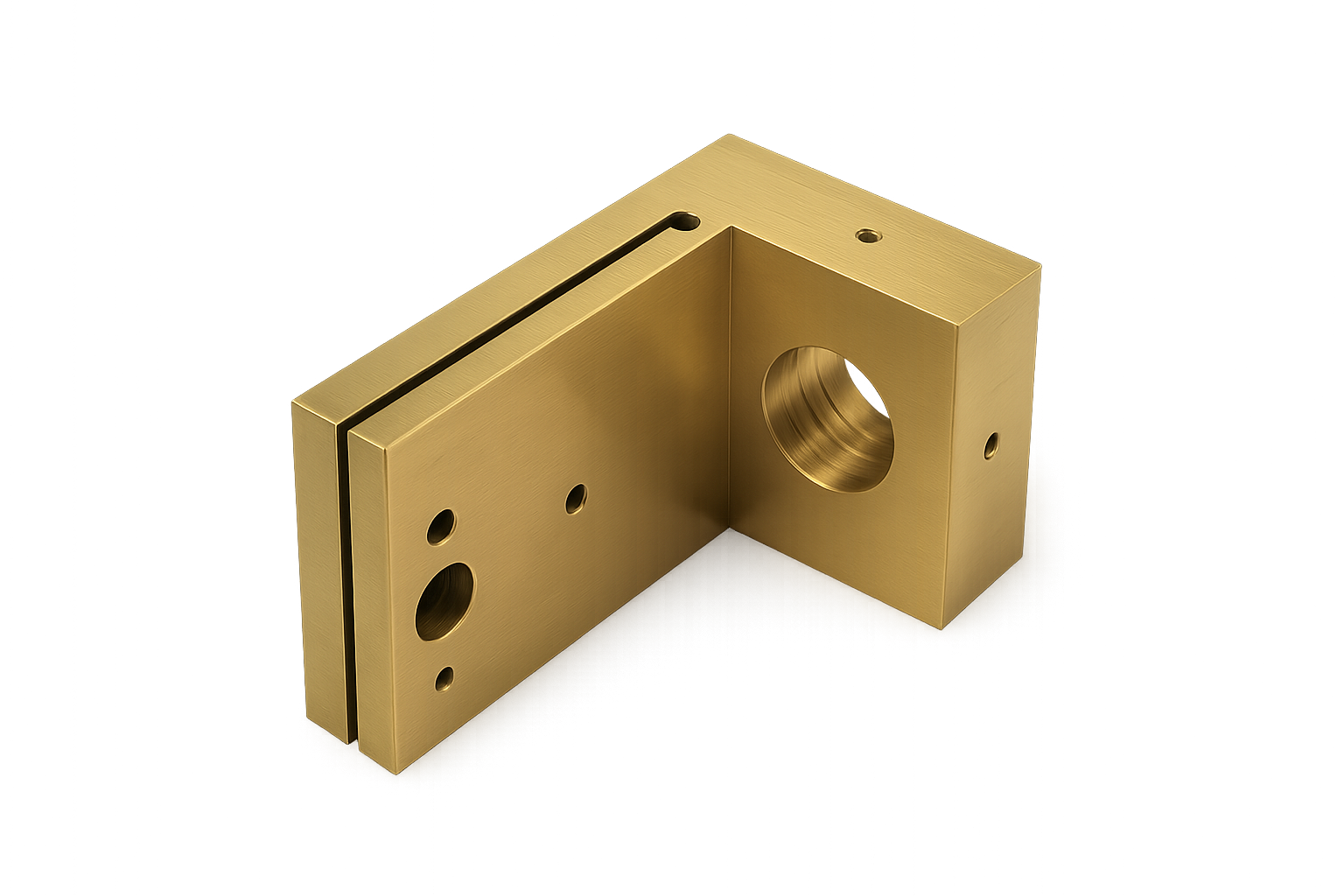

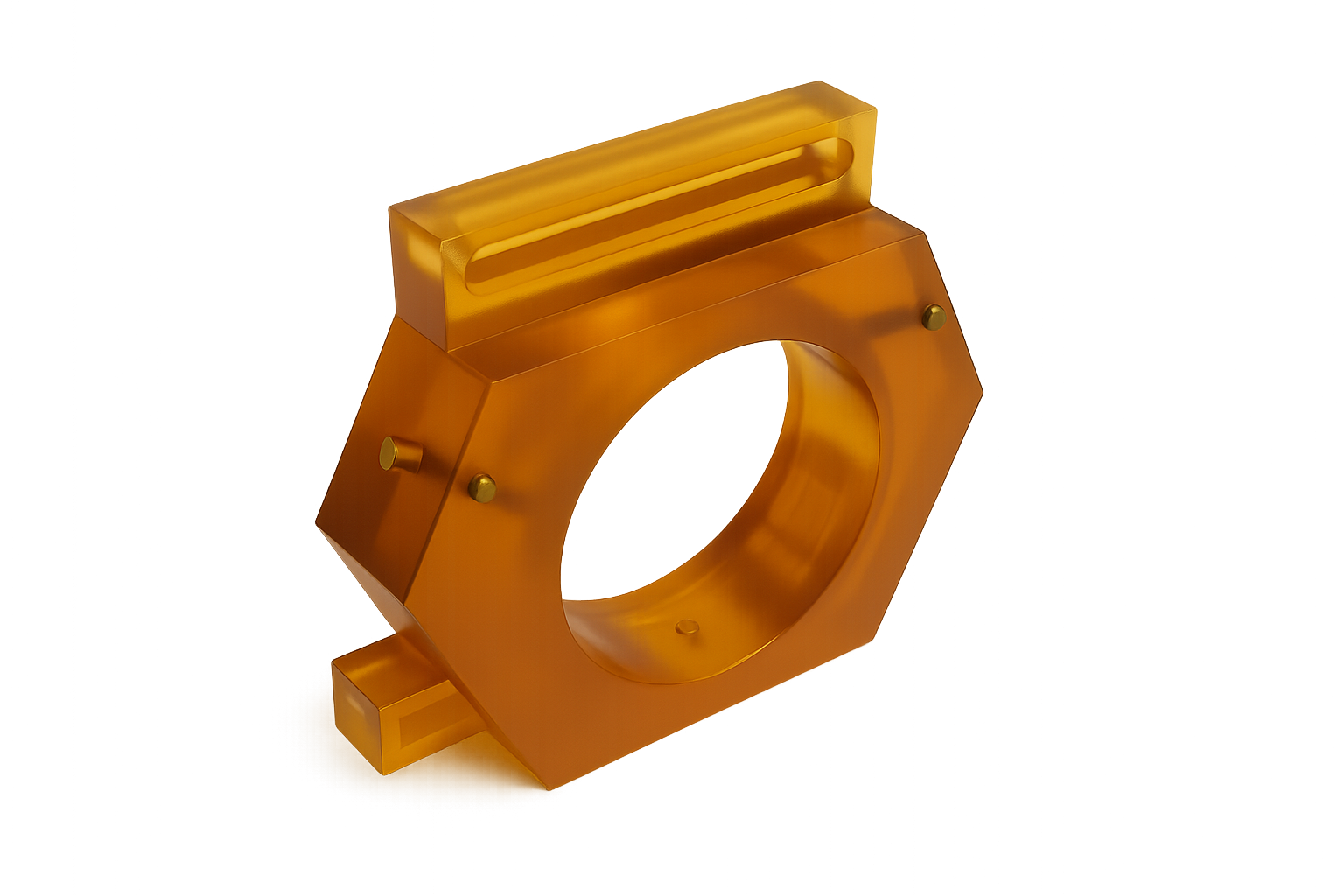

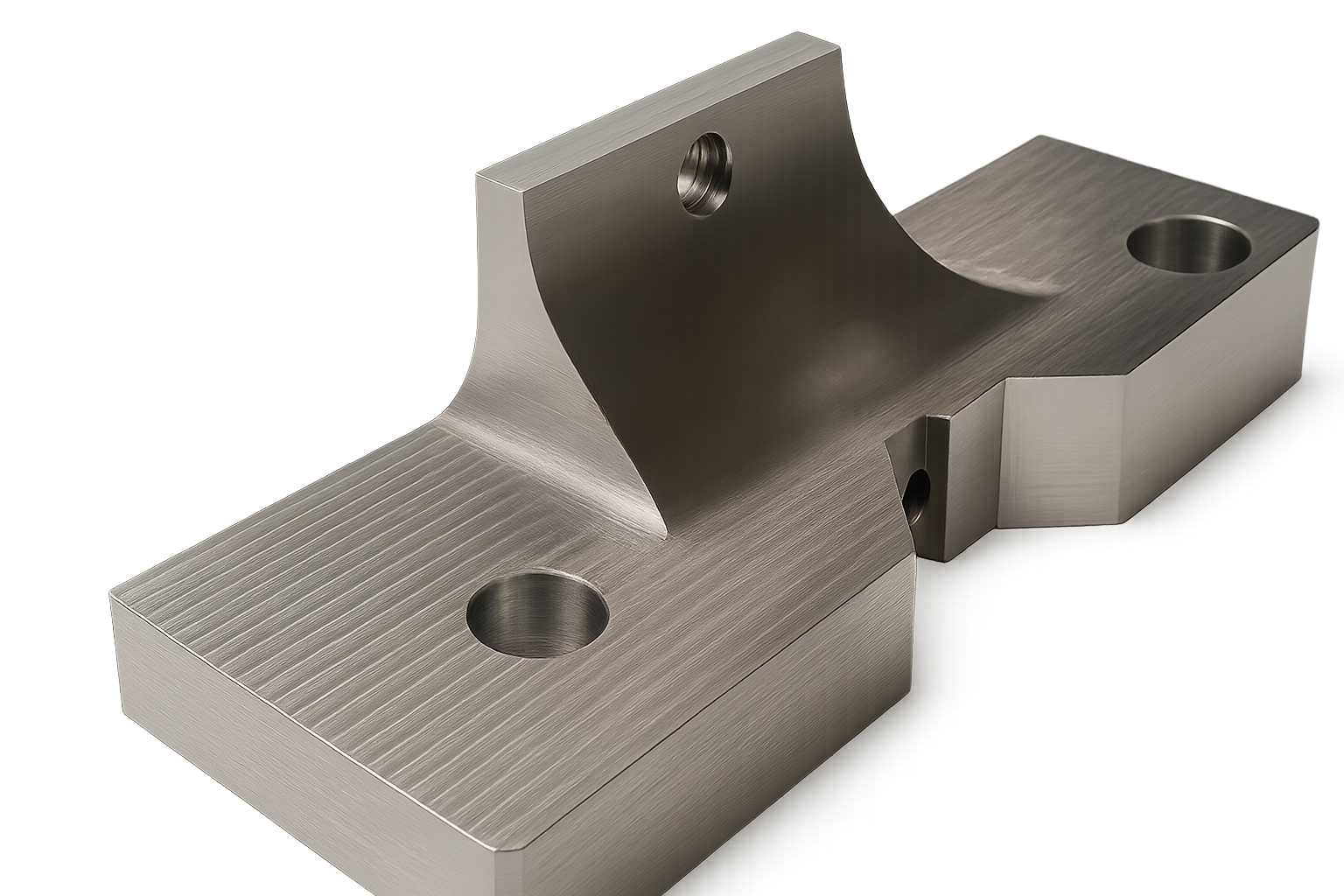

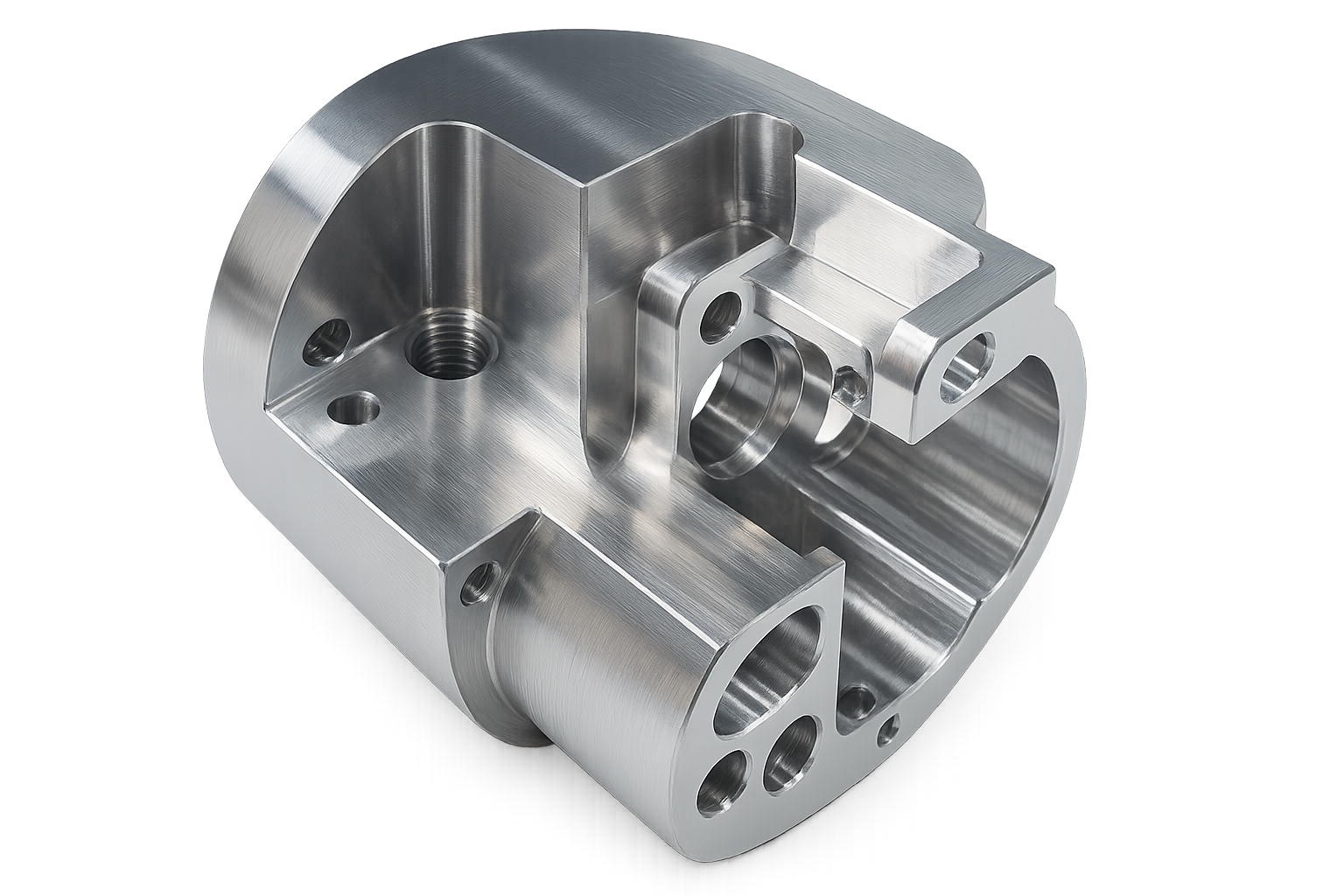

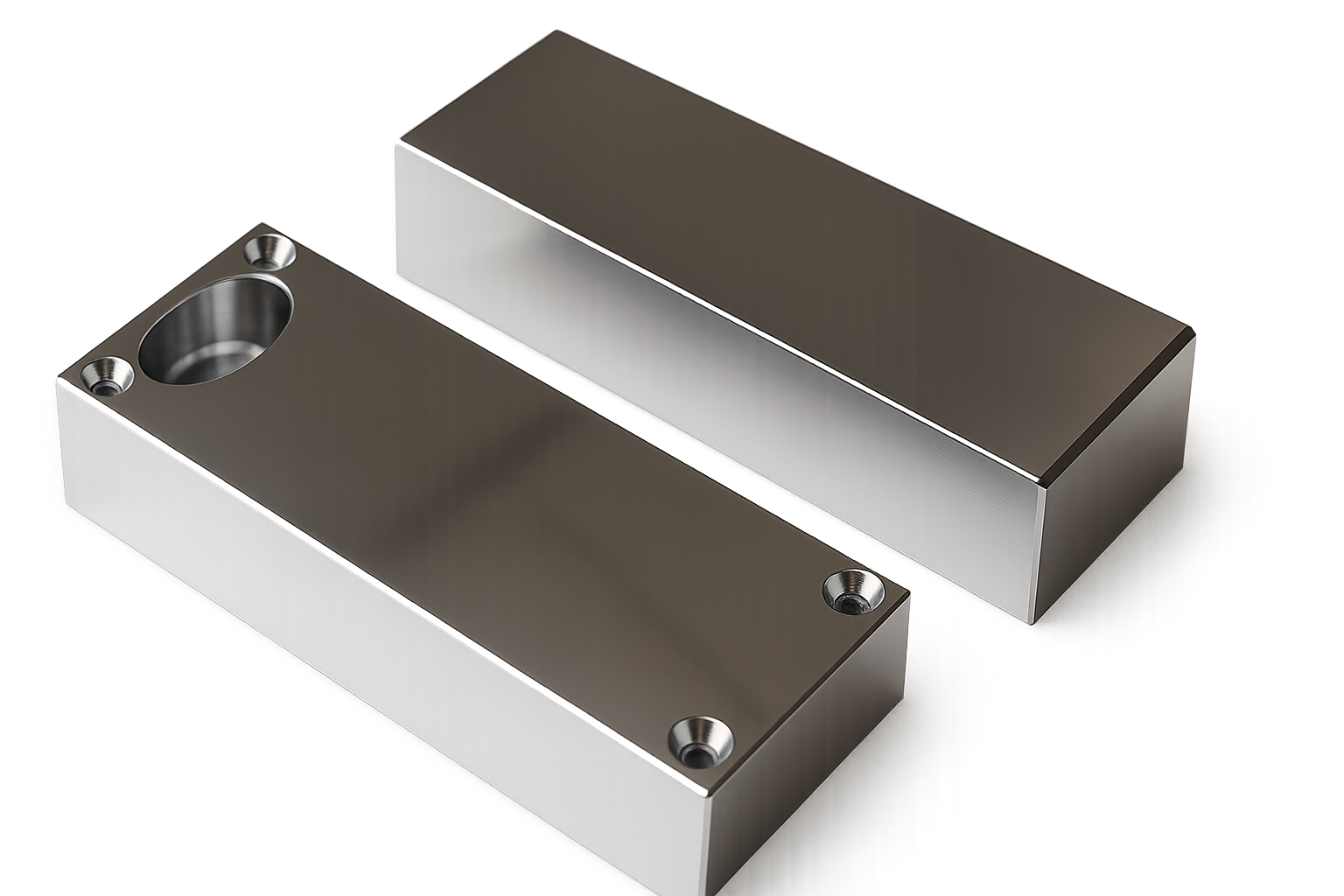

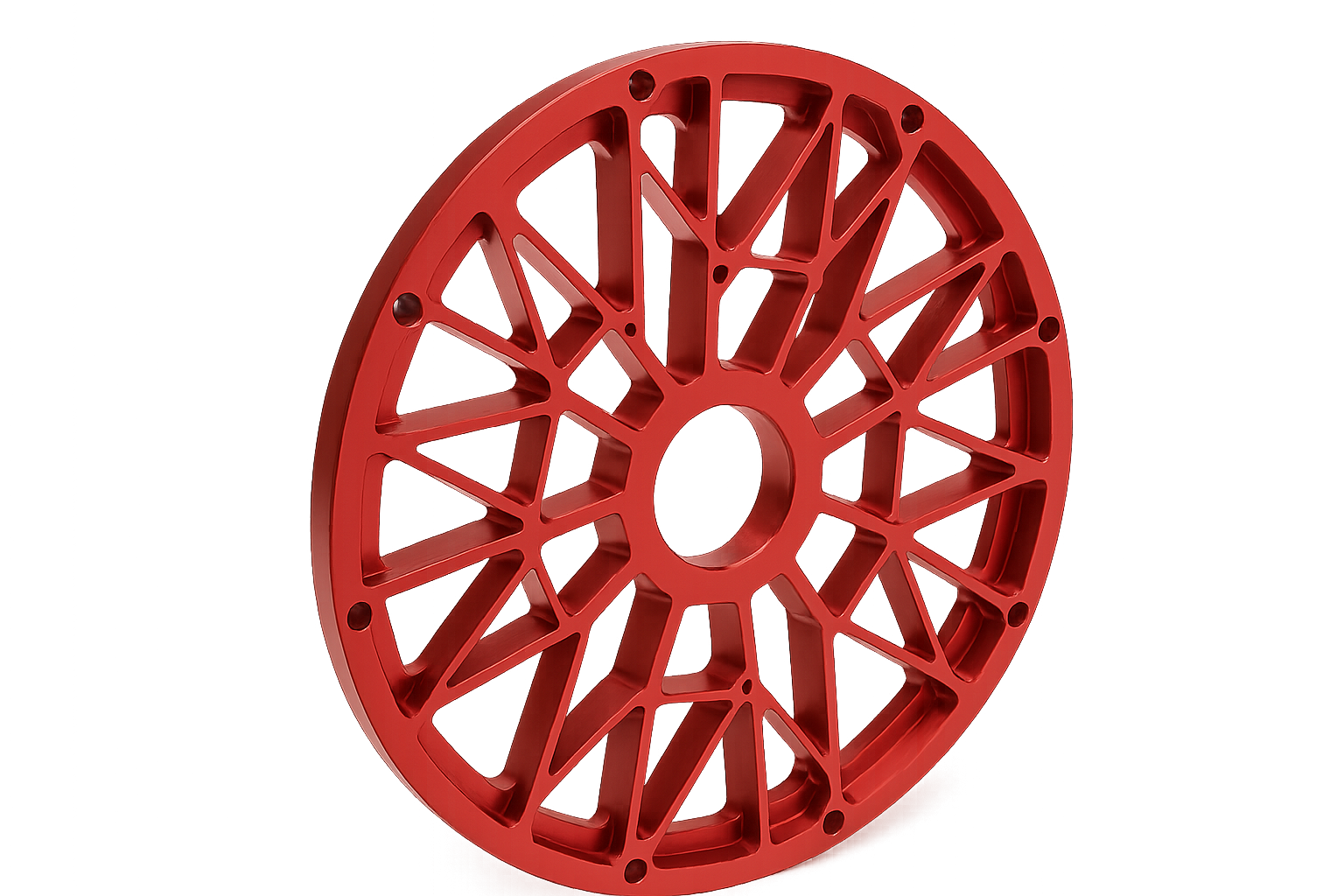

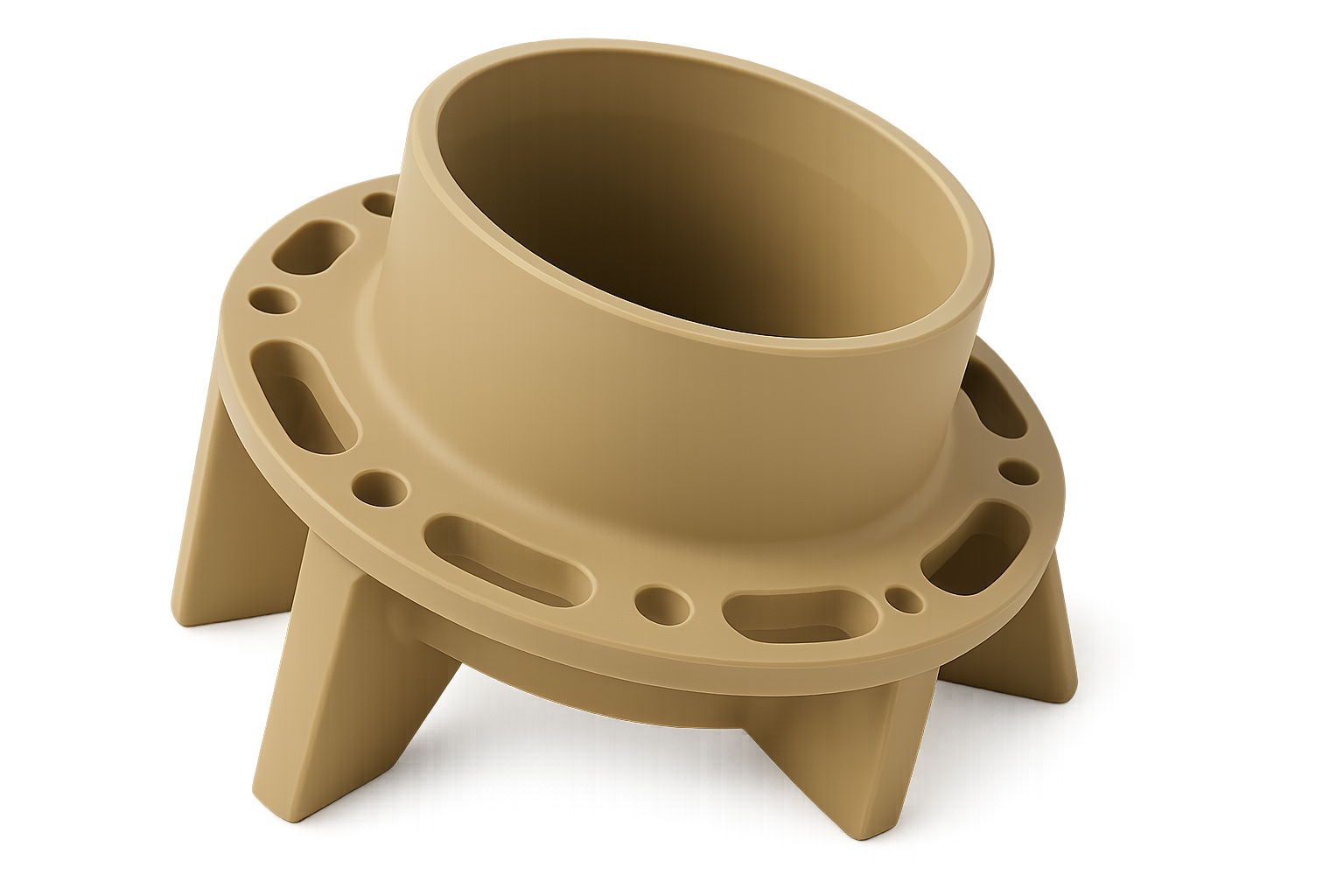

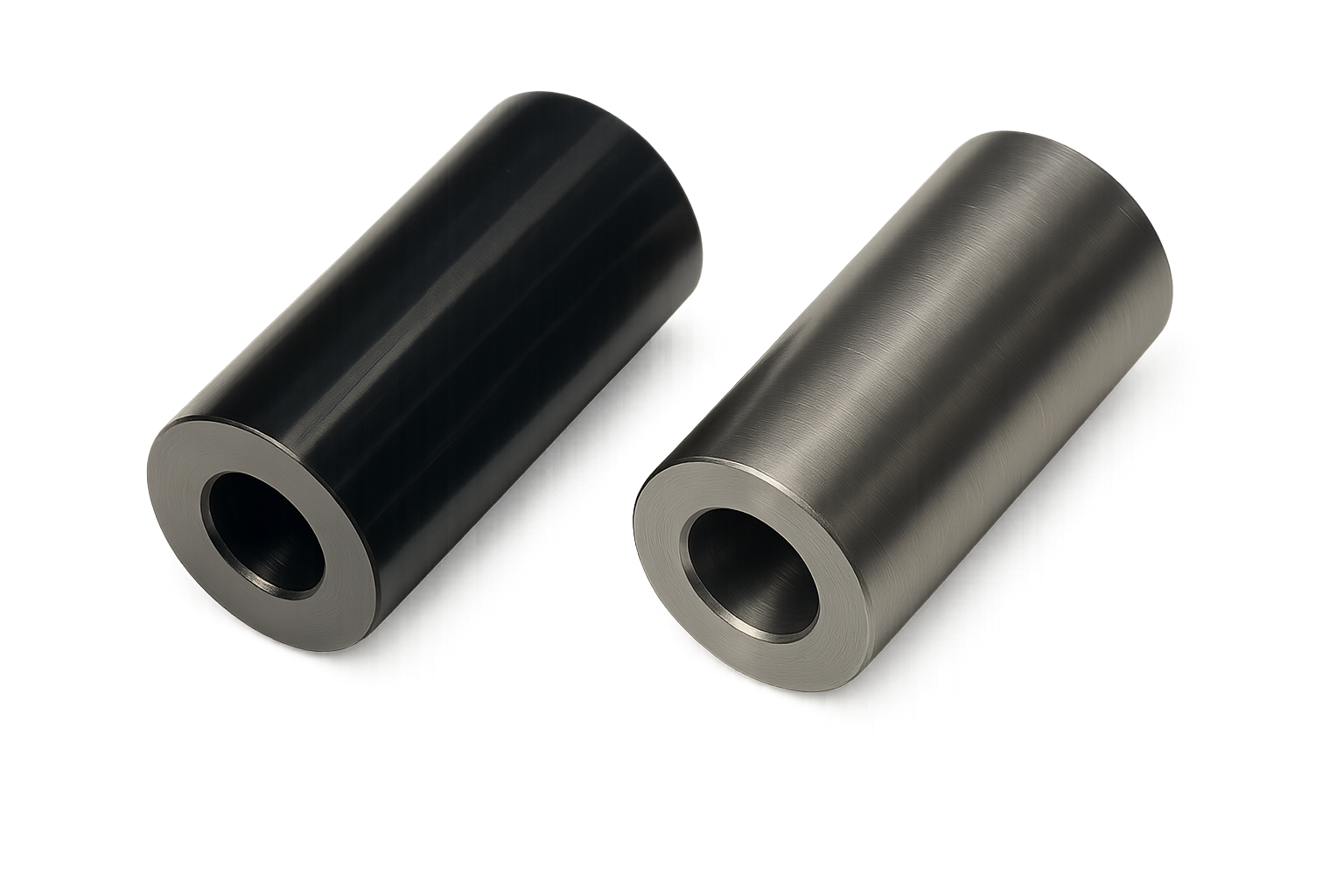

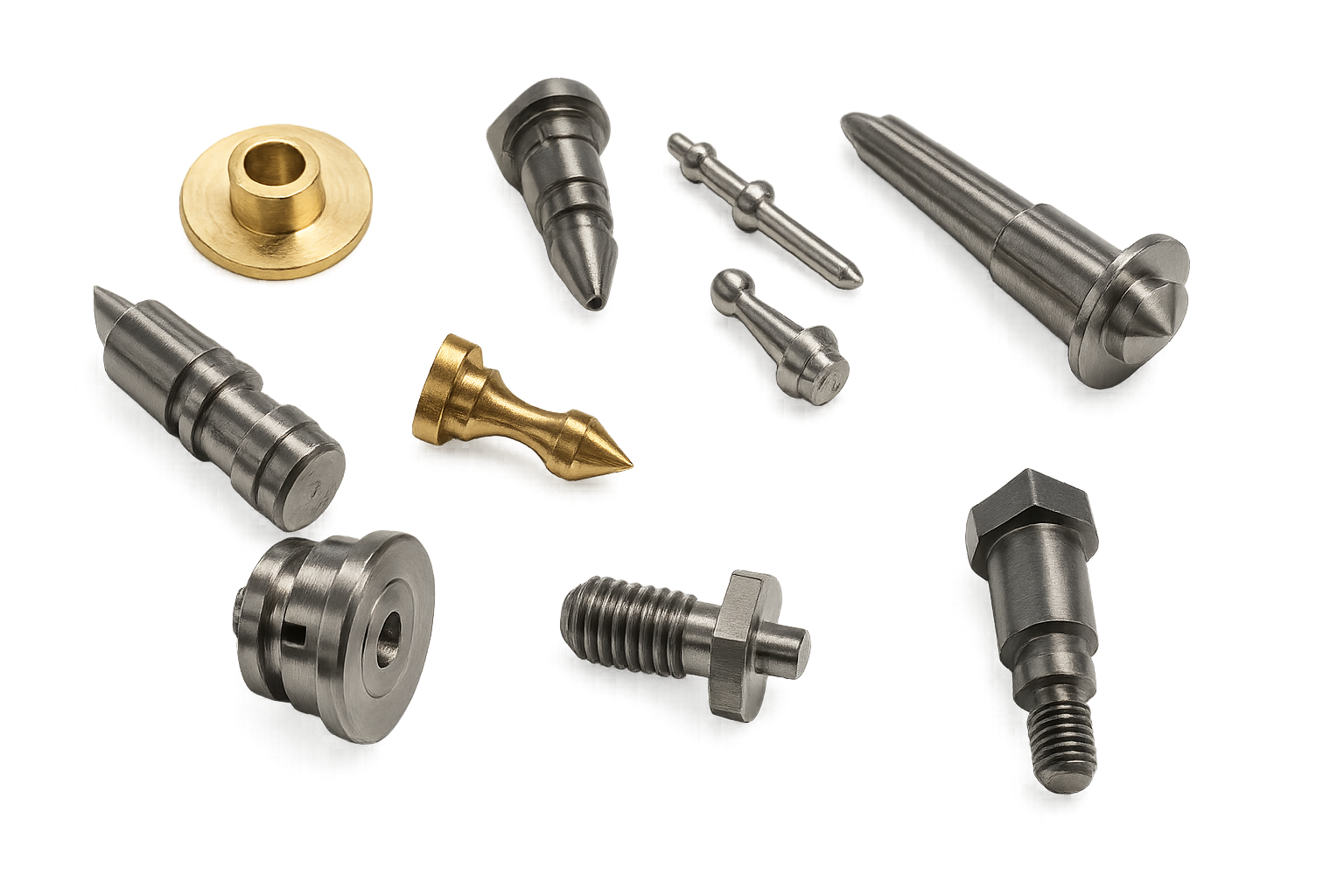

Gallery of Our CNC Machined Components

We manufacture both rapid prototypes and small to large production runs for clients across diverse sectors: medical equipment, aerospace, automotive, defense, consumer electronics, hardware innovation, industrial automation, machinery, marine, robotics, and beyond.

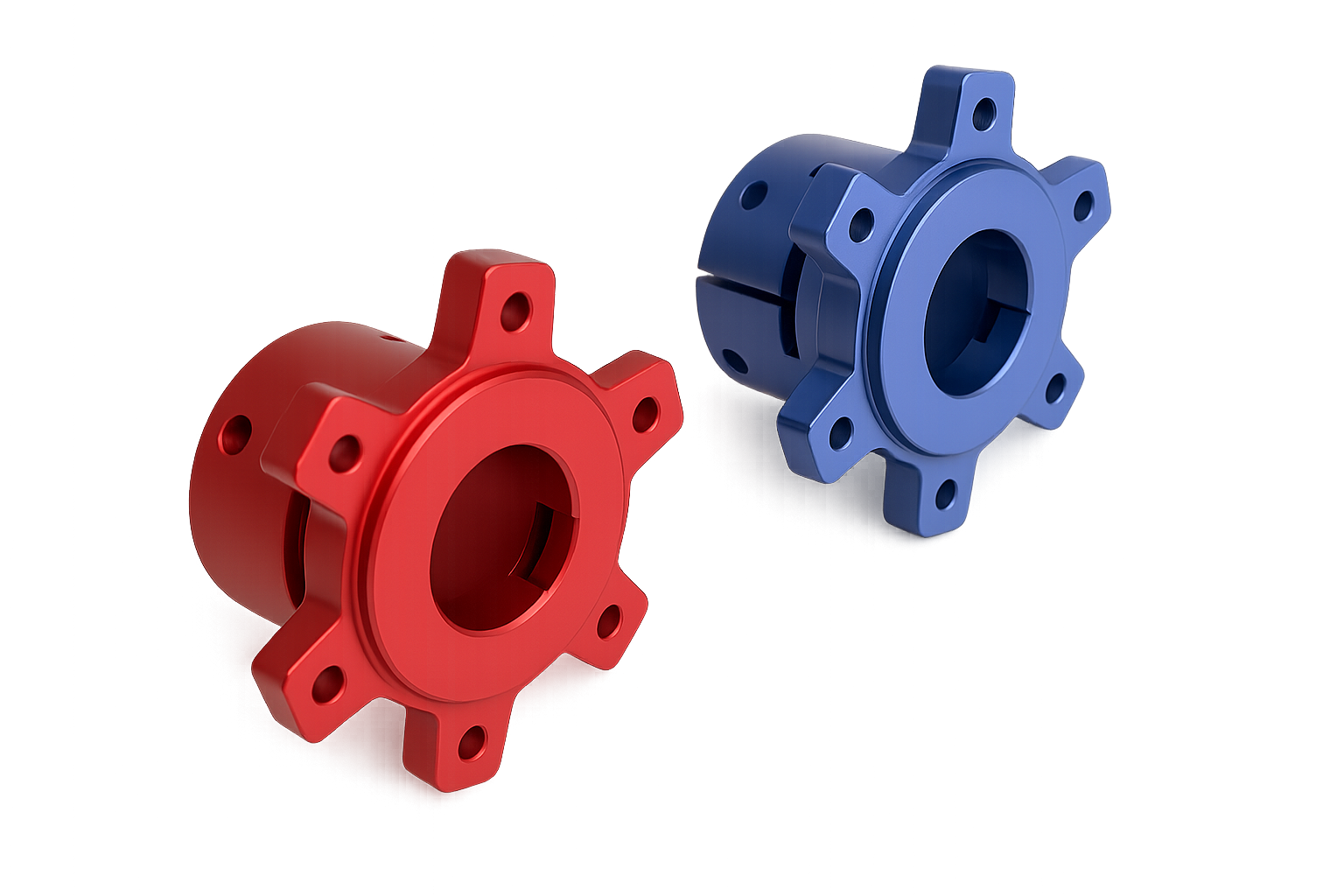

Anodizing

Anodizing

Machined

Anodizing

Surface Finishes for CNC Machined Components

In addition to our custom CNC machining capabilities, we offer a wide range of surface finishing solutions for precision parts. If you need a specific finish not listed here, feel free to contact us—we can likely accommodate your request.

As machined (Ra 3.2μm / Ra 126μin)

This is the fastest finishing option available. The parts retain visible tooling marks and may have sharp edges or burrs, which can be removed upon request.

Smooth machining (Ra 1.6μm / Ra 63μin)

Smooth Machining resembles the ‘As Machined’ finish but features reduced tool marks. Parts are produced using a slower feed rate without any manual polishing.

Polishing (Ra 0.8μm / Ra 32μin or better)

Polishing involves producing a smooth, glossy surface by mechanical rubbing or through the use of chemical treatments.

Bead Blasting

Machined components are bead blasted using glass beads, producing a consistent matte texture while minimizing visible machining marks.

Tumbled

This process uses vibrating media to tumble machined parts, effectively removing sharp edges and burrs. Tumbling is also useful for smoothing exterior surfaces by eliminating visible machining marks.

Bead blasted + Anodizing type II

Parts are bead blasted to a #120 grit finish prior to receiving Type II anodizing—perfect for enhancing aluminum's corrosion resistance and improving its visual appearance.

Bead blasted + Anodized type III (Hardcoat)

Parts are bead blasted to #120 grit before undergoing Type III anodizing. Type III (Hard Anodizing) provides a thicker, wear-resistant coating in addition to Type II’s corrosion protection, making it ideal for demanding functional uses.

Black Oxide

Black oxide is a type of conversion coating applied to steel parts to enhance corrosion resistance and reduce surface reflectivity.

Powder Coating

This finish involves coating the parts with powdered paint and curing them in an oven, creating a tougher, more wear- and corrosion-resistant surface compared to conventional painting techniques.

Chromate Conversion Coating

Chromate conversion coating enhances the corrosion resistance of aluminum and its alloys while maintaining electrical conductivity. It also serves as an effective base layer for subsequent priming and painting processes.

Plating

Includes Nickel Plating, Silver Plating, Gold Plating, Zinc Plating, Chrome Plating, Tin Plating, and more—perfect for enhancing corrosion resistance, appearance, solderability, and electrical conductivity.

DLC (Diamond-Like Carbon) Coating

DLC (Diamond-Like Carbon) coating is a durable, wear-resistant layer composed of carbon-based material that shares several key characteristics with natural diamonds.

*Additional surface finishes are available as well. Discover more about our comprehensive metal and plastic surface finishing solutions here.

CNC Machining Explained

CNC machining is a highly versatile manufacturing process that uses automated, high-speed cutting tools to produce complex parts from metal or plastic stock. Common CNC equipment includes 3-, 4-, and 5-axis milling machines, lathes, and routers, each offering different cutting dynamics depending on tool and workpiece movement. Some setups keep the workpiece fixed while the tool moves, others rotate the workpiece, and some involve simultaneous movement of both.

Experienced machinists at Sochain Precision program CNC machines using CAD models to execute accurate and repeatable tool paths for custom components. CNC machining supports nearly all metals and rigid plastics, making it ideal for industries like aerospace, automotive, medical, and electronics. Sochain Precision offers custom CNC services for more than 50 materials—from standard aluminum to high-performance metals like titanium, and engineered plastics including PEEK and Ultem 2300.

Pros and Cons of CNC Machining?

Accuracy and Precision: CNC machines at Sochain Precision are capable of achieving extremely tight tolerances, ensuring consistent quality that’s difficult to match with manual machining techniques.

Repeatability: Our CNC systems can repeatedly manufacture identical parts with the same high level of precision, making them ideal for both prototyping and high-volume production.

Speed: With optimized programming and high-speed tooling, our CNC machines enable faster part production and reduced lead times compared to traditional methods.

Flexibility: Sochain Precision’s advanced CNC equipment can be configured to create a wide variety of components from numerous materials, including metals, plastics, and composite materials.

Reduced Labor Costs: Our automated CNC operations require minimal manual intervention, reducing labor demands and helping us maintain cost-effective manufacturing solutions.

Complexity: Operating and programming CNC machinery requires specialized skills and training. Without experienced professionals, achieving optimal results can be a significant challenge.

Machine Limitations: While highly capable, CNC machines still have restrictions based on size and machine capabilities—some parts may be beyond the scope of a specific setup.

Material Challenges: Though we support a broad material range, certain alloys or composites may increase tooling wear and machining time, requiring careful process adjustments.

Why Choose Sochain for Custom CNC Machining?

Cost Efficiency

You will reduce costs by 20–30% thanks to our streamlined manufacturing processes and optimized workflows.

Guaranteed Quality

As an ISO 9001:2015 certified machining factory, we provide SGS, RoHS compliance, material traceability, and detailed inspection reports for our clients.

On-Demand Manufacturing

Our CNC milling capabilities cover everything from 1 piece to over 10,000 pieces, whether you need a prototype, small batch production, or full-scale manufacturing.

Tight Tolerance Capability

Providing tolerances from ±0.001″ to 0.005″ based on customer requirements, we specialize in manufacturing high-precision custom parts.

Wide Material Availability

Select from over 50 high-performance metals and plastics, such as ABS, polycarbonate, nylon, PEEK, aluminum, stainless steel, titanium, and copper to meet various application and industry needs.

Fast Turnaround

Enjoy reliable and on-time delivery of your parts from our CNC facility based in Dongguan, China, conveniently located near major logistics hubs to ensure smooth shipping and worry-free service.

CNC Machining FAQs

Do you have a minimum order quantity?

NO! – No minimum order required! Sochain Precision offers fast prototyping and low to mid-volume CNC machining services.

What type of design files does Sochain Machining accept for quoting?

For 3D models, we recommend STEP, IGES, or X\_T formats. For 2D drawings, we prefer PDF files with clearly marked dimensions and tolerances, if available.

How can I pay Sochain Precision?

Sochain Precision accepts payments through two methods: 1. Bank wire transfer 2. PayPal

What general tolerances can Sochain Precision achieve?

Standard CNC machining tolerances for metals are ±0.005" (±0.127 mm) in accordance with ISO 2768, unless otherwise specified. For plastics and composites, tolerances are typically ±0.010" (±0.254 mm).

What precision tolerances can Sochain Precision achieve?

High-precision CNC machining tolerances can reach down to ±0.0002" (0.005 mm). We manufacture and inspect parts to meet your specific drawing requirements.

How quickly can I get my parts?

Typical lead times are 2–3 weeks for prototypes and 4 weeks for production batches. Rush and expedited services are also available upon request.

Start Manufacturing Your Custom Parts Now!

Understanding Your Goals, Delivering Your Solutions – We’re Committed to Making CNC Machining Simple and Stress-Free!