CNC Milling Service

Get Precision CNC Milling Service for Functional Prototypes and Production Parts

At Sochain Precision, milling starts with production intent.

Datums, cutting paths, and setups match future manufacturing. This keeps the prototype useful when production begins.

Rapid prototyping and full-scale production

ISO accredited & QC checks

All in-house processes

Used in over 50 countries

FREE Instant quotations

Our CNC Milling Service Capabilities

The machining accuracy of any item/product depends upon its setup. The probability of misalignment and damage increases each time you clamp a piece to the work-holding device. We aim to minimize the number of times we set up parts and control the datums. Here are our CNC milling service capabilities.

3-Axis CNC Milling Service

3-axis milling machines mill one face of a part at a time. Afterward, the part is moved to allow milling of additional faces. Each time the part is moved, there’s a possibility of misalignment.

We typically use 3-axis milling to shape plates, brackets, and single-housing-type parts. These parts have two or more flat surfaces and simple geometric relationships between them. When properly clamped into place, these parts can hold flatness to within 0.002 - 0.005mm.

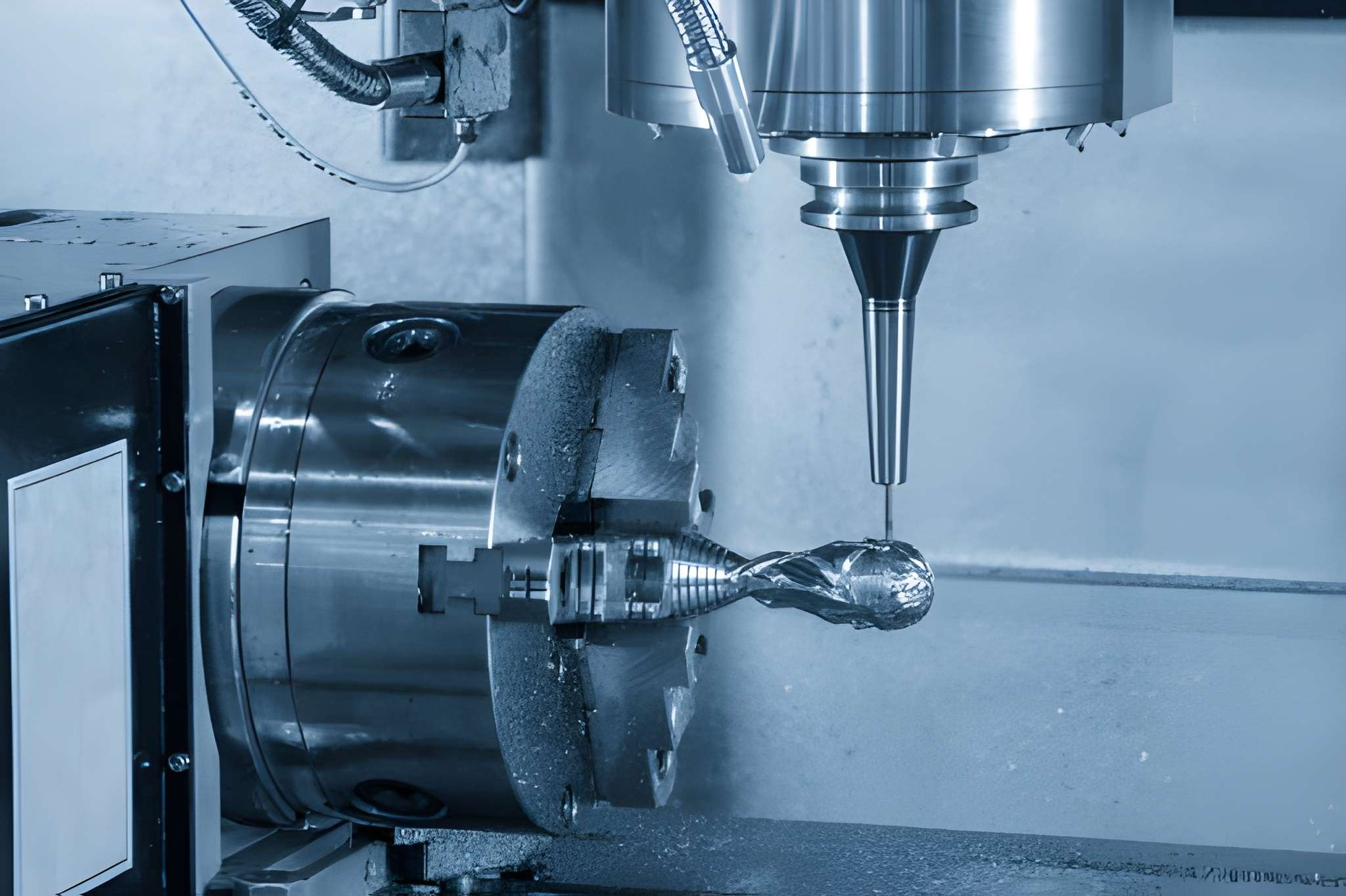

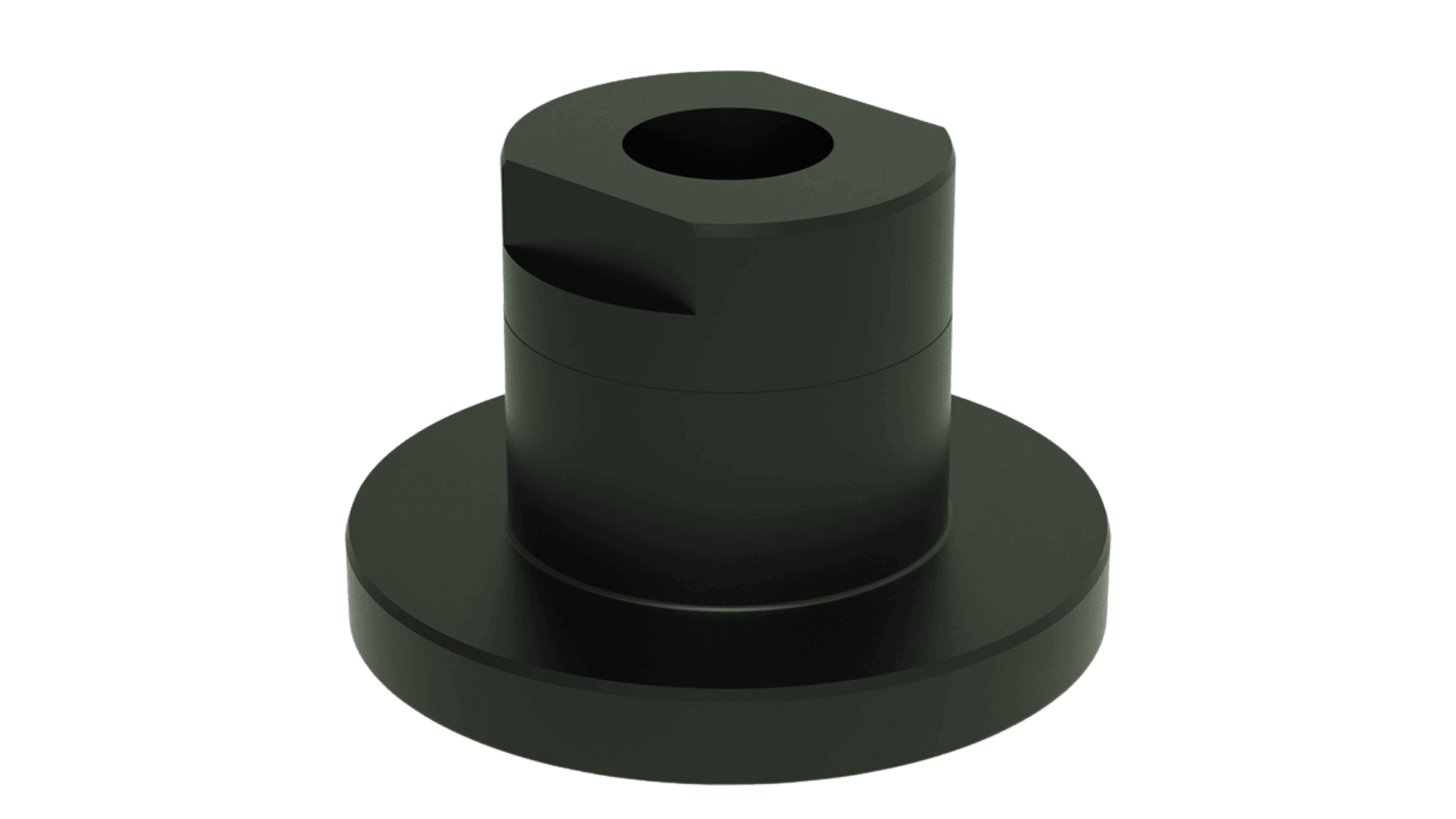

4-Axis CNC Milling Service

4-axis milling provides the capability to rotate the part during machining. This enables all features to remain aligned about a common center point, minimizes manual handling, and reduces the potential for setup errors.

It is best suited to the manufacture of housings and parts that have radial features, such as flanges, bosses, etc. In addition, hole positions can be maintained to within ± 0.001inch when the datums remain stationary.

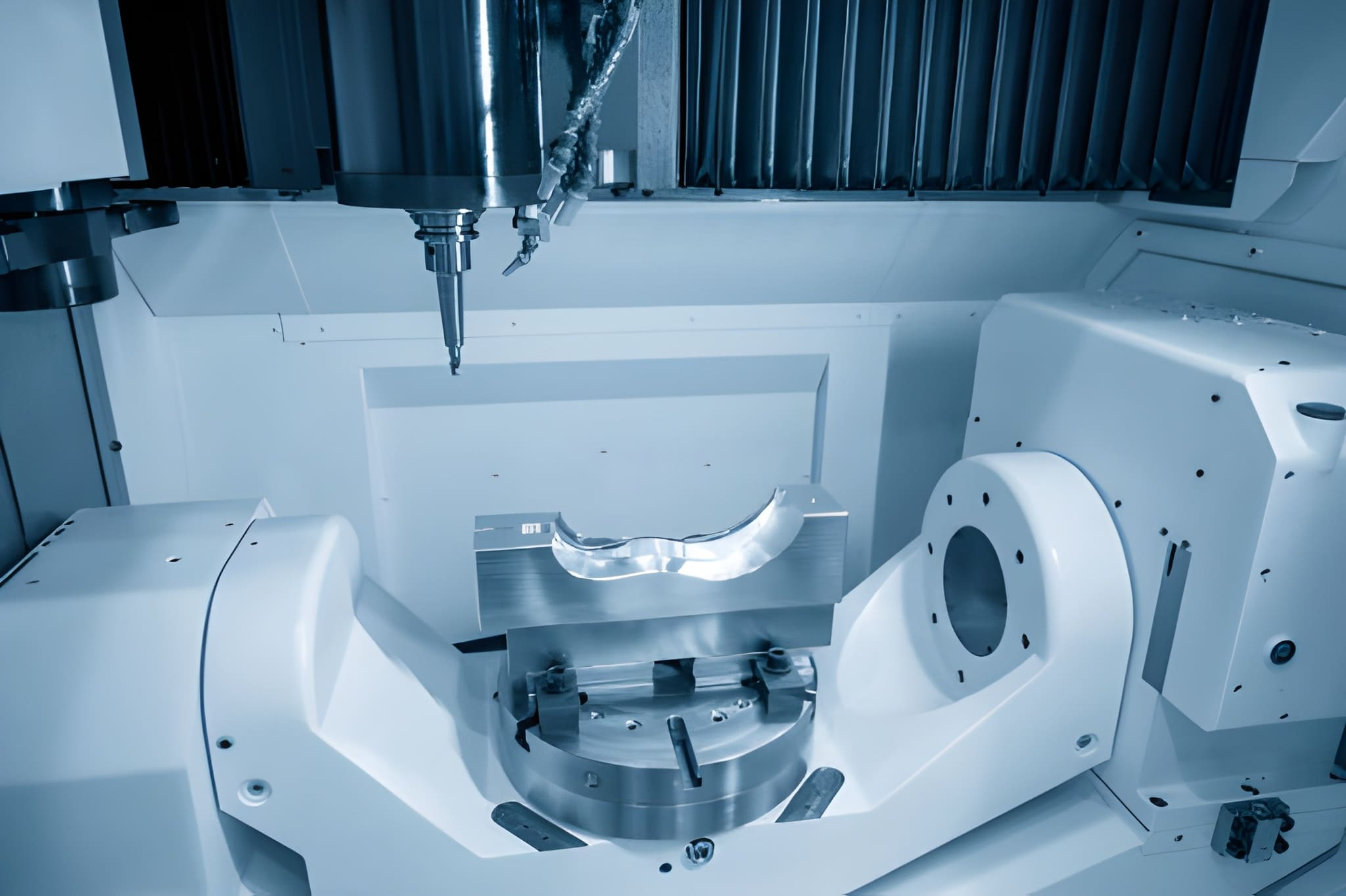

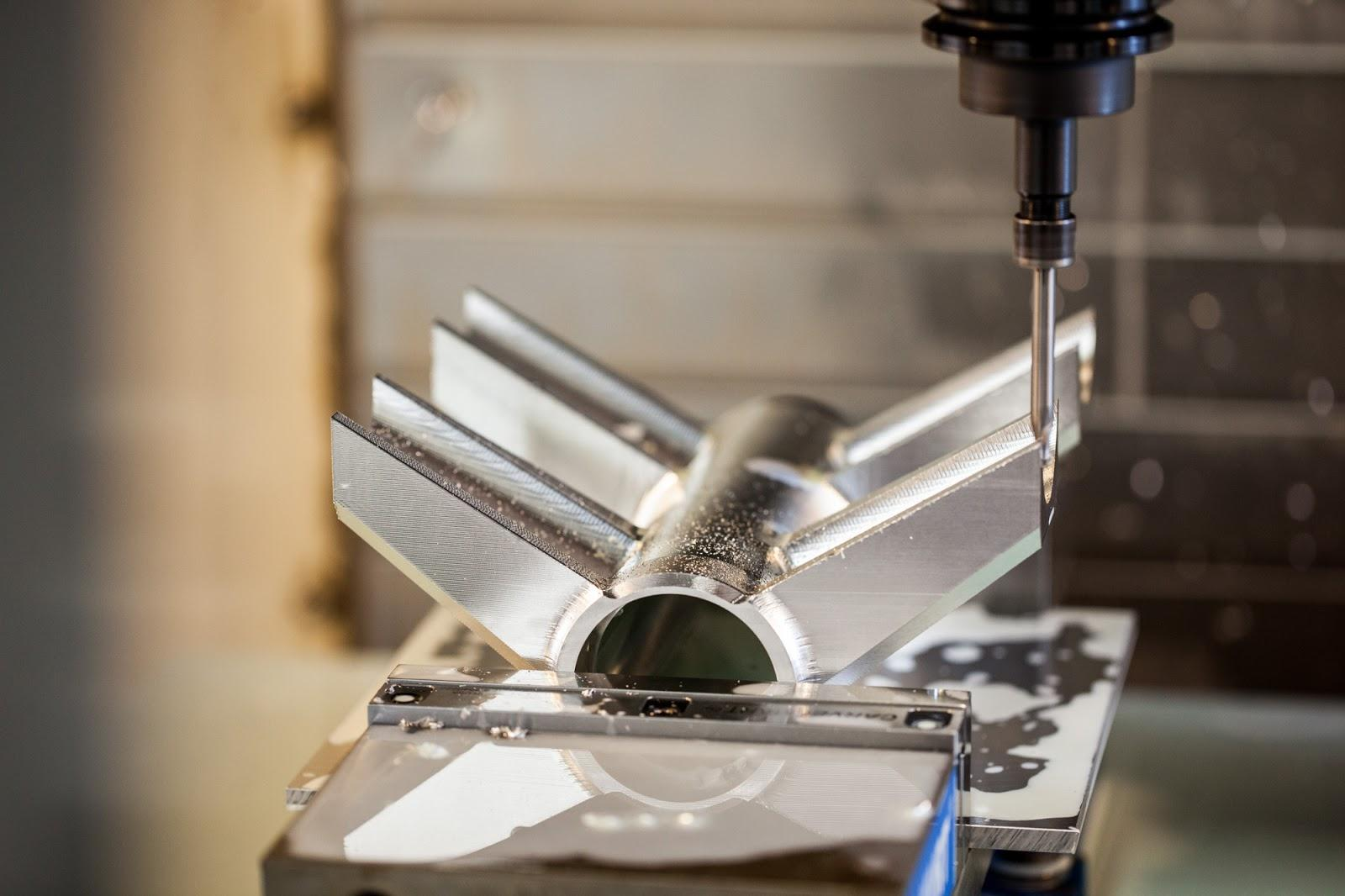

5-Axis CNC Milling Service

Five-axis milling allows the tool to approach from virtually any angle. This provides improved access to the internal areas of parts and also helps to improve surface finish by reducing tool deflection.

In addition, single setup machining enables that features are kept aligned, which is particularly important for aerospace, medical, and precision assembly applications.

Common Materials We Use in CNC Milling Service

The material selection made has a direct impact on the validity of your testing results. If soft substitutes are used, defects will be masked. Weak plastic products may warp under high load conditions. Wrong alloy selection will likely provide false strength data.

We machine the exact materials our customers use in real production, so the test results reflect actual performance.

Metals

Aluminum Alloys:

6061-T6: General Mechanical Parts7075-T6: High Strength & Load Bearing Parts5083/6082: Corrosion-Resistant PartsSteel and Stainless Steel:

1018/1045 Carbon Steel: Structural Parts303/304 Stainless Steel: Corrosion Resistance316 Stainless Steel: Medical & Marine ApplicationsOther Metals:

Brass: Fittings & Wear PartsCopper: Electrical & Thermal PartsTitanium: Aerospace & Medical PartsPlastics

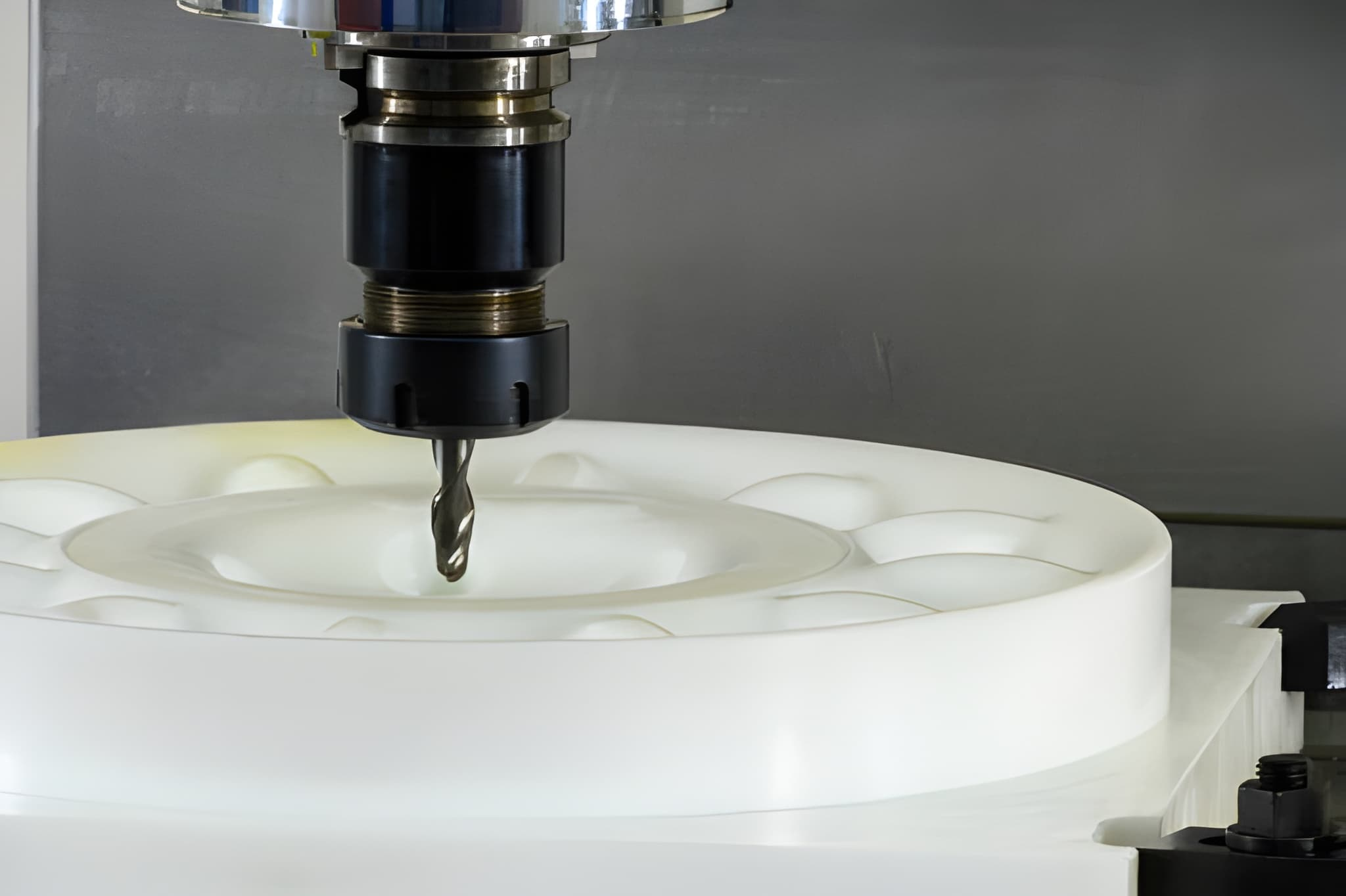

Plastics are machined using low cutting stresses to prevent heat buildup and subsequent warping.

POM:Gears, Bushings, Sliding Blocks, Precision SpacersABS: Enclosures, Covers, Control Housings, Fixture BodiesNylon (PA6, PA66):Wear Pads, Rollers, Guides, Bearing SleevesPEEK: High Temperature Brackets, Insulating Parts, Chemical Resistant ComponentsPTFE:Seals, Valve Seats, Low Friction Pads, Sliding RingsPolycarbonate (PC):Transparent Covers, Impact Guards, Inspection WindowsPMMA (Acrylic): Light Covers, Display Panels, Optical ComponentsPBT:Electrical Connectors, Sensor Housings, Dimensionally Stable PartsUHMW-PE: Wear Strips, Conveyor Guides, Impact PlatesPPS:Automotive Sensor Parts, High Temperature Electrical ComponentsFR-4: Insulating Plates, PCB Fixtures, Electrical Mounting Panels

CNC Milling Surface Finishes

Surface finish can directly influence assembly fit, performance, and wear down the part. It must be chosen based on function, not appearance only.

Surface Finish | Application/Use |

As machined | Functional testing, dimensional validation, lowest cost option, internal or hidden parts |

Anodizing | Corrosion protection for aluminum housings, brackets, and structural parts |

Hard anodizing | Wear-resistant surfaces, sliding interfaces, bearing areas, and increased surface hardness |

Powder coating | Environmental protection, scratch resistance, cosmetic parts exposed to handling |

Sand blasting | Uniform texture, removal of tool marks, and surface preparation before coating |

Polishing | Reduced friction, improved sealing surfaces, mating, and contact areas |

Electroplating | Electrical conductivity, wear resistance, and corrosion control on metal parts |

Black oxide | Steel part protection, glare reduction, minimal impact on dimensions |

Electropolish | Medical, food, and fluid-contact parts require smooth and clean surfaces |

Our CNC Milling Tolerances and Standards

Tight tolerances cost money. They must be included only when needed. Tolerances should match function, not habit. Applying unnecessary precision increases cost and lead time without improving performance. We define tolerance levels based on how each feature affects assembly, motion, and load.

Feature Type

Practical Tolerance Range

General features

±0.02 mm

Mating faces

±0.01 mm

Critical fits

±0.005 mm

Standards Applied | Practical Use |

ISO 2768-m | General machining, where no specific tolerance is defined |

GD&T | Applied only to functional features such as alignment, position, and concentricity |

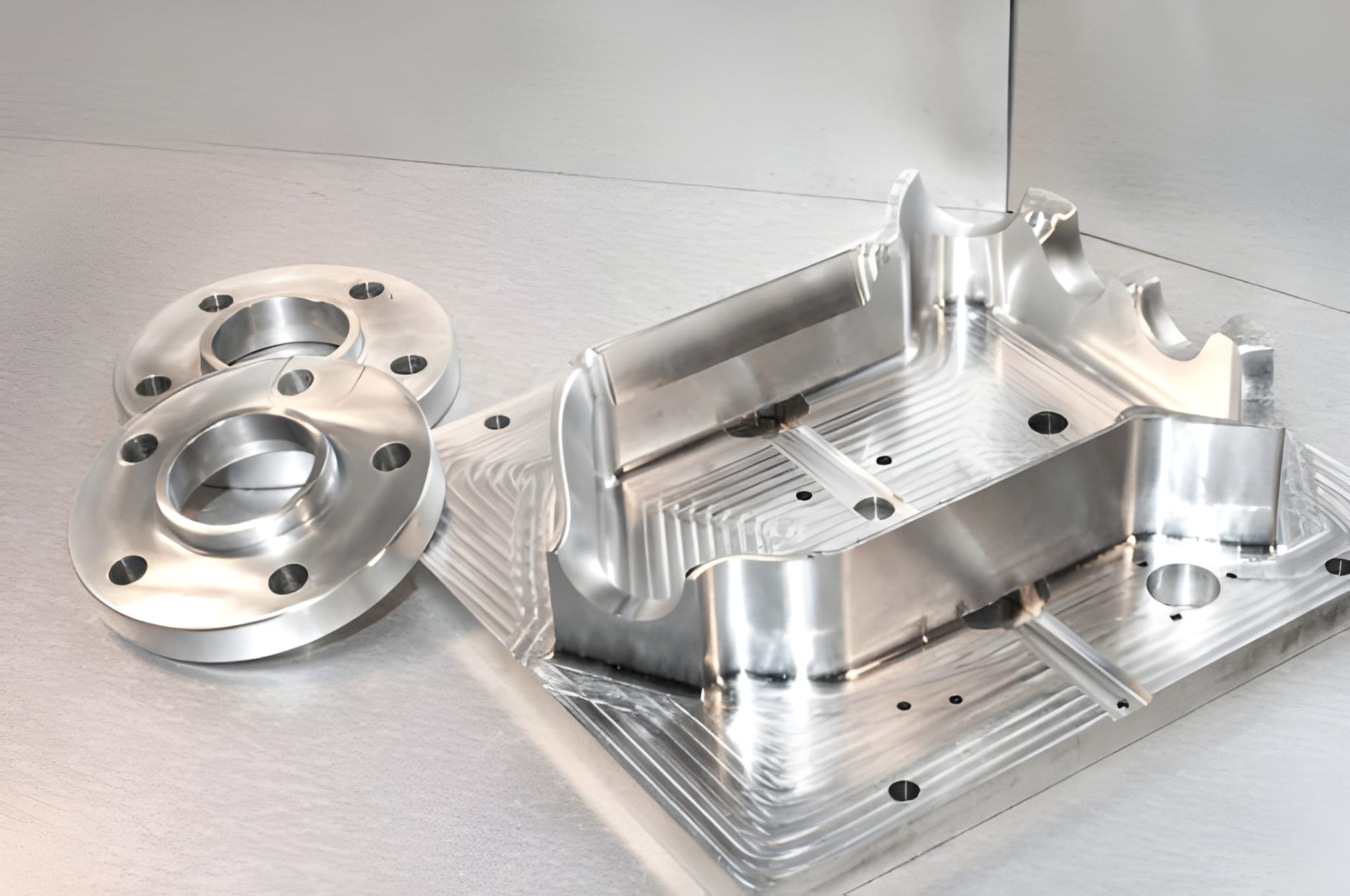

CNC Milling Service From Prototype to Production

While CNC machining may have been viewed as an interim measure in some cases, the truth is that CNC milling is not simply a temporary activity. If prototypes are made differently from production parts, problems will show up later in manufacturing. Hole positions will change; fits will vary; also, assemblies will fail.

To prevent this from occurring, we lock down the datums and machining logic early so that all reference points (datums) used from the prototype to production will remain the same.

Therefore, there will be no need to recreate tool paths as the volume of your product increases; your dimensions will remain the same.

Rapid CNC Milling Service for Design Validation

The primary purpose of producing design validation prototypes with CNC milling is to produce them exactly as they were designed, including thin walls, deep pockets, and fine threads. The reason - many of these features typically fail first and, therefore, need to be examined early in the development phase.

Therefore, we will use your final materials and strict tolerances when manufacturing your design validation prototypes. By doing this, we can spot potential problems that your CAD model did not capture — specifically regarding the assembly of your product, and how it behaves under actual loading conditions. Our common checks include:

Fit behavior of holes and shaftsFlatness of mating surfacesThread engagement depthDeformation due to clampingHeat expansion on aluminum and plastic

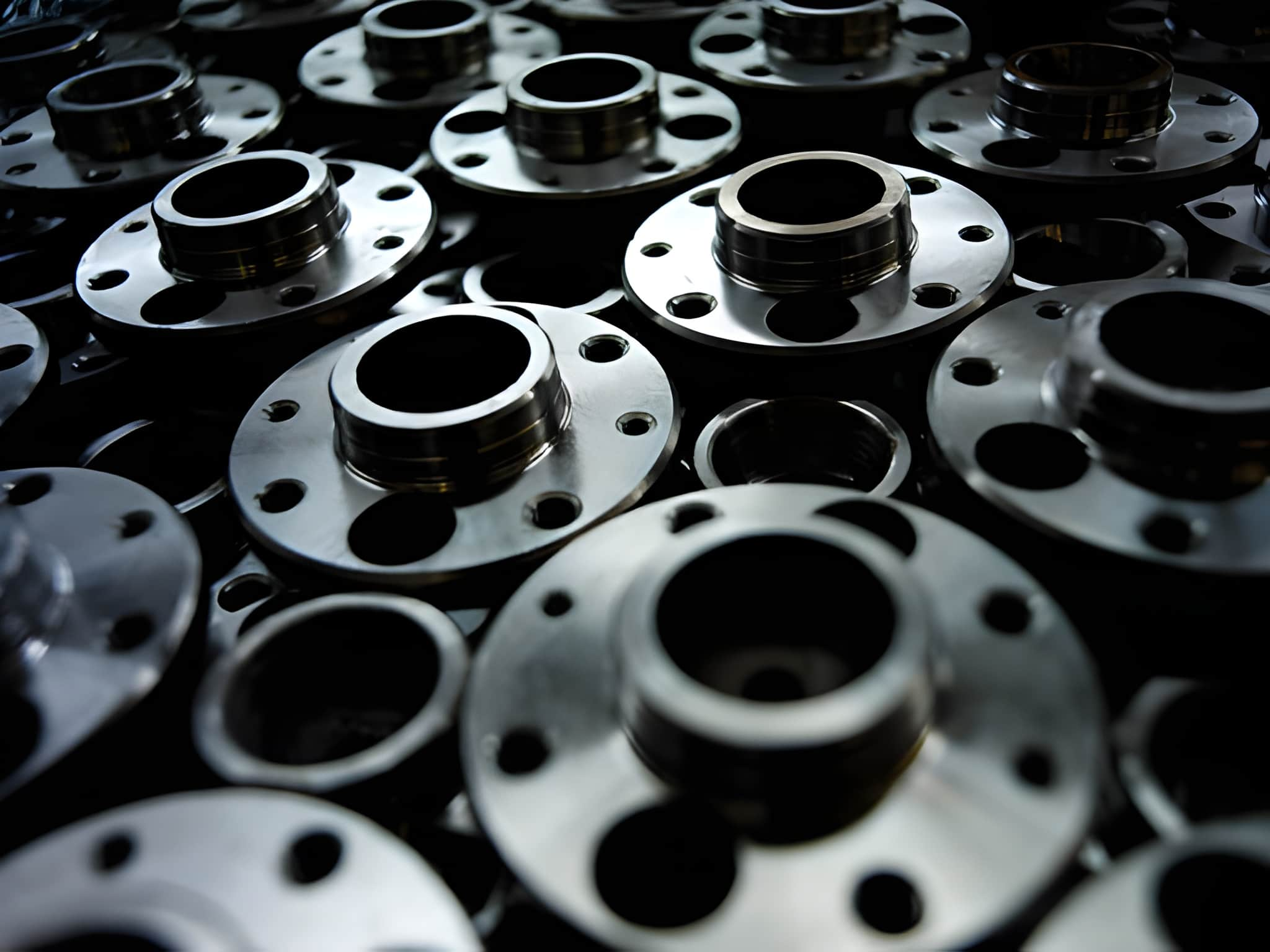

Low-Volume CNC Milling Service

A low-volume production run acts as a bridge between testing/prototyping and the actual production of your product. Our team always monitors cycle time and tooling behavior to provide you with realistic information about costs and performance.

This phase of your product's development is used to evaluate manufactureability multiple units of your product - not just samples. At this point in time, you will start to see variations between your parts and what your product's tolerance sensitivities are. Additionally, this is where you will determine your part's assembly time and tool access.

Typically, low-volume production runs range anywhere from 20 to 500 pieces. Your final quantity will depend upon your product's design, complexity, and material.

Production CNC Milling Service

Once we start to manufacture your product, the stability of the production process remains our first priority. We will harden your fixtures; standardize your tools; and fix your machining sequence(s).

In addition, we will check your critical dimensions at predetermined times. If we detect any deviation in your process, we will correct it before any parts fail.

Since you had already validated your process during prototyping, you do not have to worry about any unexpected outcomes when you scale up your production process. Our typical production control includes:

Monitoring the tool lifeEstablish inspection checkpoints within the production processOptionally perform Statistical Process Control (SPC) on critical featuresDefining acceptable limits for each featureIndustries Using Our CNC Milling Service

Each industryhas specific requirements when it comes to intended part use. Therefore, we must tailor our machining strategy and inspection depth to meet the demands of your specific application.

Automotive

Automotive products experience vibrations, temperature changes, and repeated assembly/disassembly. Therefore, brackets must remain aligned; mounting holes must remain accurate; and the parts must not deform under load.

Our focus is on positional accuracy and stiffness. Typically, we conduct tests on prototypes of automotive parts under actual vehicle operating conditions before obtaining final approval.

Aerospace

Aerospace products require extremely high levels of control over their geometry and surface finish. For example, burrs, tool marks, and uneven surfaces can create areas of high stress concentration.

Therefore, we carefully examine flatness, parallelism, and edge condition. In addition, we utilize multi-axis machining to ensure accuracy on complex shapes.

Medical

Medical devices and components demand consistently accurate dimensions and smooth, unblemished surfaces. In addition, sharp edges and surface imperfections must be controlled.

As such, we document your inspection records for validation purposes. High repeatability of inspection results across small batches of parts is crucial for securing final approval.

Robotics and Automation

Components of robotic systems rely heavily on precise alignment. Specifically, bearing seats, shaft centers, and mounting faces must remain concentric and parallel.

Small deviations in alignment can reduce accuracy and shorten service life. Therefore, we utilize CNC milling to maintain these relationships.

Industrial and Consumer

Industrial products frequently contain combinations of tight and loose tolerances. While applying tight tolerances to every aspect of a product will certainly add expense, it will not necessarily improve the product.

Therefore, we only apply precision to those aspects of your product that are required to function properly. In addition, consumer products require clean edges and a consistent appearance to obtain a favorable assessment.

In addition, we believe that it is better to take a practical approach to CNC milling rather than an academic one. Therefore, we welcome the opportunity to discuss your needs and develop a customized solution that meets your requirements and budget.

Our CNC Milling Machining Service Workflow

Our workflow reduces rework by addressing problems early. Speed without control creates delays later.

Upload CAD Files and Quotation

Drawings are meticulously reviewed by our engineers. Geometry, tolerances, and materials are thoroughly inspected. Unrealistic requirements are flagged before pricing. So, our quotes are based on actual machining time, setups, tooling, and inspection effort.

Design for Manufacturability Review

Before machining starts, we review common risk areas:

Sharp internal cornersThin vibrating wallsDeep pockets with small toolsTolerances are tighter than the function requiresCNC Milling and Process Control

Machining starts from a fixed datum. Stress release and distortion are managed through the sequencing tool. Multi-axis machining is used to reduce the setups and overall expense. Tool wear is monitored on critical features. This helps prevent size variation across parts.

Final Inspection and Delivery

Critical dimensions are checked using calibrated tools or CMMs when required. Threads, edges, and surfaces are manually inspected. Pare delivered according to development schedules. Delays caused by rework are avoided.

Start Your CNC Milling Service With Sochain Precision

Send your files for review so our engineers can review your design and provide direct feedback. We only start production when the approach is stable and clear. Our goal is simple. Make parts that work the first time and continue to work in production.

FAQs

- What materials can I use for CNC milling?

We mill metals like aluminum, stainless steel, titanium, and brass. In addition to metals, plastic options like POM, ABS, Nylon, and PEEK are also available. You can choose based on strength, heat resistance, and testing needs.

2. How accurate are your CNC-milled parts?

General features are ±0.02 mm, mating faces ±0.01 mm, and critical fits ±0.005 mm. We maintain accuracy with careful setups and meticulous inspections.

3. Can you handle complex shapes or angled surfaces?

Yes, our 3-, 4-, and 5-axis machines handle deep pockets, angled surfaces, and radial features, and keep the parts aligned.

4. Do you offer surface finishes for milled parts?

Yes, options include anodizing, hard anodizing, powder coating, sandblasting, polishing, and black oxide. Finishes are applied to match function and durability needs.

5. Can I order small batches or low-volume production?

Yes, we produce batches from 20 to 500 parts, so you can test fit, function, and cost before full production.

Start Manufacturing Your Custom Parts Now!

Understanding Your Goals, Delivering Your Solutions – We’re Committed to Making CNC Machining Simple and Stress-Free!