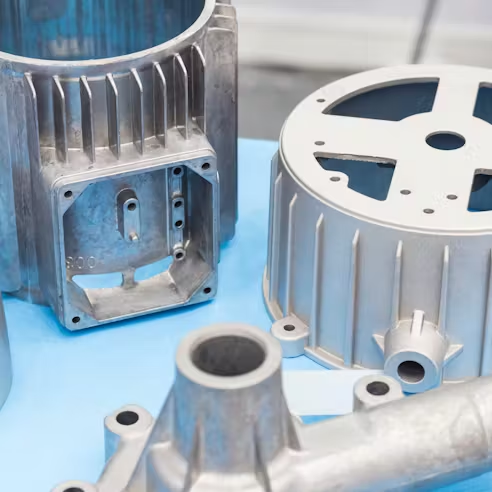

Custom Die Casting Services

High Quality Die-Cast Metal Components.

Start Your Die Casting Quote Here

STEP | STP | SLDPRT | IPT | PRT | SAT files

Die Casting Process

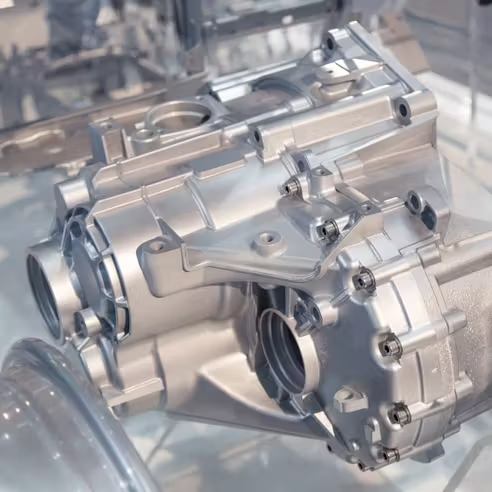

Die casting is an ideal manufacturing method for producing large quantities of complex metal components and is valued for its precision, dependability, and efficiency. This process minimizes or eliminates the need for secondary operations, though post-machining is often used to achieve tighter functional tolerances. Die cast parts can also receive the same surface finishes commonly used on CNC-machined components.

Much like injection molding, die casting requires a custom mold—known as a die—that may include single or multiple cavities. This process is best suited for low-melting-point alloys such as aluminum, zinc and magnesium. Molten metal is injected into the die, taking the shape of the cavity and solidifying before being ejected. Depending on the specific needs of the job, die casting may use either low- or high-pressure techniques, with metal introduced via ladle or plunger.

Die casting enables consistent, high-volume production of complex parts with tight tolerances. Advanced techniques like squeeze casting and semi-solid metal casting are used to produce top-quality parts across a wide range of industries. Most die casting operations focus on either aluminum, zinc alloys or magnesium, with aluminum accounting for about 80% of all parts made.

At Sochain Precision, our experienced team carefully evaluates and personally quotes each die casting project to match your exact specifications—delivering a seamless, efficient manufacturing experience. Explore more about our process and services below.

Sochain's Die Casting Service

Request A Quote

Email us your design files, and our team will work closely with you to confirm your requirements, timeline, and budget align with your project goals. A DFM report will be provided for review and approval before we proceed with tooling.

Confirm Your Sample

After your project begins, we’ll create a precision-engineered die. Once the tooling is complete, we’ll provide initial part samples, known as T1s, for your review and approval.

Kick Off Production

Once you approve the samples, we proceed with full production and ship your parts on schedule. With Sochain Precision managing the entire supply chain and logistics, you can count on a smooth process. You retain full ownership of your tooling and can place repeat orders anytime to match your production needs.

Die Casting Services Available from Sochain

Sochain Precision works with experienced die casting partners who use advanced equipment and modern technology to produce high-quality, on-demand parts for a wide range of industries. Our services specialize in the two main die casting methods: hot chamber and cold chamber casting. Both techniques are capable of creating parts with intricate designs, tight tolerances, and excellent mechanical strength.

Hot Chamber Die Casting

Often referred to as gooseneck casting, the hot chamber die casting method is one of the most widely used techniques in the industry. It’s ideal for casting low melting point metals like zinc, magnesium, and lead. In this process, a built-in or attached furnace keeps the metal molten inside a holding pot. A component called the gooseneck channels the molten metal from the pot into the injection cavity of the die. A plunger sits above the chamber and, when activated, pushes the molten metal up through the gooseneck and into the mold. The die remains clamped shut while the part cools and solidifies. Once cooled, the mold opens, and the finished part is ejected using ejector pins.

Cold Chamber Die Casting

In the cold chamber die casting process, the shot chamber stays at ambient temperature and doesn’t include a built-in holding pot for molten metal. Instead, the metal is melted in a separate furnace and manually ladled into the chamber through a pouring hole. Unlike hot chamber systems, the cold chamber setup connects the mold directly to the shot chamber, and a hydraulic ram pushes the molten metal into the die cavity under high pressure. The metal is held in place as it solidifies, ensuring a dense and precise casting. This method is ideal for metals with higher melting points, such as aluminum and its alloys.

Metal Materials for Die Cast Parts

There are a variety of metal materials available for die casting, and the right choice depends on how the final product will be used. For example, aluminum die cast parts are widely used in automotive and aerospace applications where strength, corrosion resistance, and weight savings are critical. Below, we’ve outlined the key die casting materials we commonly work with. If you have a specific alloy or requirement in mind, feel free to reach out—we’re happy to help!

Aluminum Die Casting

Aluminum alloys are among the most commonly used materials for die casting due to their excellent performance and workability. Their full recyclability and ease of casting make them a top choice for both manufacturers and engineers. Since aluminum has a relatively high melting point, it is typically processed using the cold chamber die casting method.

Cast aluminum components are favored for their impressive strength-to-weight ratio, reliable dimensional stability, and compatibility with a variety of finishing options. Additional benefits of aluminum die casting include:

Ability to withstand high operating temperatures

Natural corrosion resistance

Good stiffness and rigidity

High thermal and electrical conductivity

Designers can select from several high-performance aluminum alloys based on application needs. Popular choices available at most aluminum die casting facilities include:

A360.0 – Offers excellent corrosion resistance and fluidity

A380.0 – The most commonly used alloy, balancing cost and performance

A383.0 (ADC12) – Ideal for intricate parts requiring better flow characteristics

A413.0 – Known for its excellent pressure tightness and castability

These alloys serve industries like automotive, aerospace, consumer electronics, and more, offering consistent quality and performance in demanding applications.

Zinc Die Casting

Zinc is one of the most cast-friendly materials used in die casting, making it ideal for high-volume production runs. It is primarily used in hot chamber die casting due to its excellent flow characteristics and low melting point. These properties allow zinc to fill complex mold geometries quickly and produce parts with thin walls, fine details, and tight dimensional tolerances.

Thanks to its fast solidification rate, zinc die casting supports the shortest cycle times, offering unmatched efficiency in mass production. Its balanced mechanical and physical properties make it a go-to material for a wide range of applications. Key benefits include:

Excellent impact resistance

High surface hardness

Dimensional stability over time

Smooth surface finish suitable for plating

Fast cooling and solidification due to low melting temperature

We provide a variety of commonly used zinc die casting alloys, including both Zamak and ZA series. Some of the most popular options include:

Zamak 2 (ZA-2) – Offers excellent strength and hardness

Zamak 3 (ZA-3) – The most commonly used zinc alloy, known for stability and castability

Zinc alloys are widely used in automotive, electronics, consumer goods, and hardware due to their cost-effectiveness, ease of casting, and ability to create intricate parts with excellent surface finishes.

Surface Finishing Options for Die Cast Parts

Zinc and aluminum-zinc components can remain in their as-cast state and still offer decent corrosion resistance. Aluminum castings, however, generally require additional coatings to enhance their resistance to environmental factors. When parts are removed from the die, they often show rough areas where the sprues were attached, along with visible marks from ejector pins. As-cast zinc surfaces typically achieve a roughness of 16-64 microinch Ra.

The surface of the part is finished with a uniform, non-glossy texture.

Aluminum parts are often treated with anodizing to boost surface protection. Type II anodizing forms a corrosion-resistant oxide layer, available in multiple color options. However, due to the surface characteristics of die cast aluminum, achieving a smooth cosmetic finish through anodizing can be challenging. Type III anodizing, also known as hardcoat, offers additional wear resistance along with corrosion protection. Note that anodized surfaces are non-conductive.

All die-cast components are compatible with powder coating. In this process, dry powder is electrostatically applied to the part’s surface and then cured in an oven. The result is a tough, durable layer that resists wear and corrosion better than traditional liquid paint. A broad selection of colors is available to achieve your preferred visual finish.

All die-cast components can be coated using wet paint, available in a wide range of colors and formulations to suit different functional and aesthetic requirements.

Die cast components can be finished with a variety of plating options, including electroless nickel, nickel, brass, tin, chrome, chromate, Teflon, silver, and gold for enhanced performance and appearance.

Manufacturers can apply chromate conversion coatings to aluminum parts to boost corrosion resistance and enhance paint or primer adhesion. These chemical film coatings also maintain electrical conductivity.

Our die cast components undergo vibratory tumbling with specialized media to eliminate sharp edges and refine surface finishes for improved part quality.

Applications of Die Casting

Thanks to its flexibility and high-efficiency output, die casting is an excellent choice across many industries and applications. It’s particularly ideal for producing small to medium-sized parts with intricate designs. Common uses include components for electronics, industrial machinery, automotive systems, aerospace assemblies, and medical equipment. When large quantities of complex metal parts are needed—especially those too big for processes like Metal Injection Molding (MIM)—die casting offers a reliable, scalable solution.

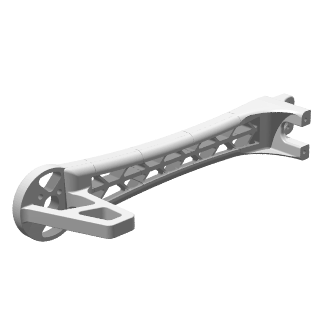

- Aerospace & Automotive Components

- Connector Housings

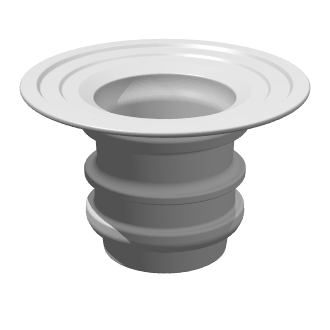

- Pumps and Plumbing Fixtures

- Outdoor lighting

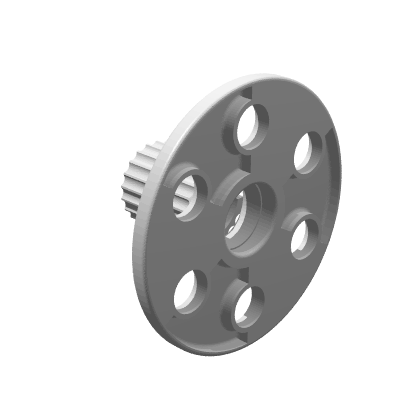

- Gears

- Appliances and Lighting

Die Casting Advantages and Disadvantages

Advantages of Die Casting

Complex Designs Made Easy

Our die casting process allows us to manufacture complex parts with thin walls and intricate shapes that are both strong and dimensionally consistent.

High Strength and Heat Resistance

Compared to plastic molding, our metal castings deliver greater strength and superior performance under high temperatures. Materials like aluminum provide excellent strength-to-weight ratios for demanding applications.

Tight Tolerances with High Precision

We maintain standard tolerances between +/-0.003″ and 0.005″ per inch, and we can achieve precision down to +/-0.001″ based on your part’s requirements, material, and geometry.

Wide Range of Custom Finishes

We offer multiple finishing options—from smooth or textured surfaces to painting and plating. These finishes help improve corrosion resistance and elevate the product’s appearance.

Disadvantages of Die Casting

Tooling Investment

Although die casting offers low unit costs for large batches, the initial cost for tooling and upkeep can be significant. That said, our experienced team ensures the tooling is optimized for longevity and performance, maximizing your return on investment.

Best for Medium to High Volumes

Because of the tooling expense, die casting is most cost-effective when producing over 1000 parts. If your project meets that scale, we’ll help you take full advantage of the process’s efficiency and consistency.

Longer Setup Times

Die casting requires a series of pre-production steps—like DFM reviews, mold design, tool manufacturing, and first article sampling—that may take several weeks to complete. However, our in-house engineering support and project managers streamline every stage to minimize delays and keep your project on schedule.

Our dedicated team collaborates with you every step of the way, offering proactive recommendations and production strategies to shorten lead times and meet your project’s exact needs.

FAQs

We work with commonly used die casting alloys including aluminum, zinc, and magnesium, chosen for strength, finish quality, and application requirements.

Our die casting process accommodates a wide size range of parts, from small precision components to larger structural castings, based on part design and quantity.

Yes. We provide complete mold and tooling design development, including flow simulation and optimization to improve part quality and production efficiency.

Sochain Precision supports medium to high-volume die casting production, with scalable capacity to meet batch sizes from thousands to millions of pieces, depending on customer requirements.

We offer multiple post-casting finish options including deburring, polishing, anodizing, plating, painting, and powder coating to meet functional and aesthetic needs.

Yes. We can produce sample or prototype castings to confirm specification, fit, and finish before moving to full volume production.

We apply in-process inspection, tooling verification, and final dimensional checks using calibrated equipment to ensure parts meet tolerance and specification requirements.

Yes. Our engineering team can review and optimize designs to improve manufacturability, reduce material waste, and enhance structural performance.

Kick Off Production Of Your Custom Components Today!

Focusing on Your Needs, Providing the Right Solutions – We’re Dedicated to Making CNC Machining Efficient and Hassle-Free!