Metal CNC Machining

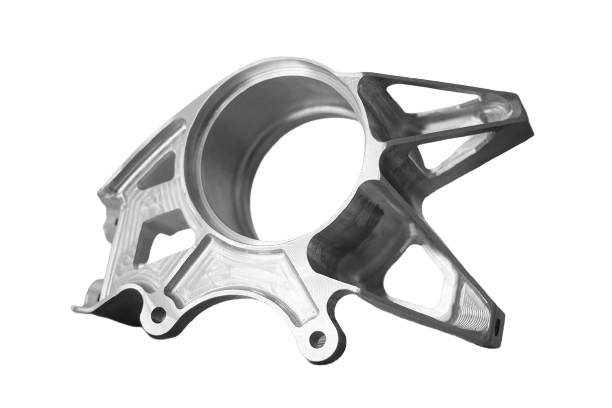

Sochain provides a wide selection of metals for CNC machining, perfectly suited for both functional prototypes and high-precision custom production parts across multiple industries.

- Affordable Pricing

- Quality Material Certifications

- Rapid Lead Times

- Worldwide Shipping

CNC Machining Metal

Selecting the right metal for CNC machining requires looking at several key factors. The material you choose directly impacts the final part’s performance. For instance, it may need to withstand heat, resist deformation, or maintain strength under load. At Sochain, we help you evaluate corrosion resistance, machinability, cost, weight, and surface appearance to ensure the perfect fit for your project.

Image | Name | Description | Price |

|---|---|---|---|

| Aluminum | Excellent workability + Outstanding strength-to-weight balance | $ |

| Stainless steel | Smooth machinability + Strong tensile properties + Excellent corrosion resistance | $$$$ |

| Steel | Easy to machine + Superior strength + Long-lasting corrosion protection | $$$ |

| Brass | Efficient cutting performance + High mechanical strength + Rust-resistant | $$ |

| Copper | Reliable machinability + Durable under stress + Protective against corrosion | $$ |

| Titanium | Consistent machinability + Tough under load + Stable in harsh environments | $$$$$ |

| Magnesium | Low weight + Exceptional strength-to-weight performance + Great heat transfer + Safe for medical use | $$$ |

| Molybdenum | Robust mechanical strength + Outstanding resistance to heat and corrosion | $$ |

Aluminum

Aluminum is one of the most economical metal choices for CNC machining. In addition to its affordability, it offers a great strength-to-weight ratio and dependable performance, making it perfect for producing lightweight precision parts.

Moreover, aluminum is highly machinable, enabling fast and cost-effective production. Several aluminum grades are commonly used in CNC machining, including:

AL6061-T6 is the most commonly used aluminum alloy in CNC machining. It’s a cost-effective option known for its outstanding machinability, ease of fabrication, and resistance to atmospheric corrosion. However, it has limited resistance to saltwater and harsh chemicals.

This aluminum grade is well-suited for machining structural parts, aerospace fittings, and transportation components.

AL7075-T6 is a premium-grade aluminum alloy known for its exceptional strength, making it a top pick for CNC machined parts in sectors such as aerospace and automotive. Its high toughness, ductility, and fatigue resistance make it ideal for producing structural components subjected to heavy stress.

This aluminum grade is frequently chosen for CNC machining. Among the 6000 series alloys, 6082 offers the highest strength—surpassing even 6061.

Its superior strength comes from a high manganese content, which helps refine its grain structure. With excellent corrosion resistance, 6082 is a strong candidate for applications in the aerospace and defense industries.

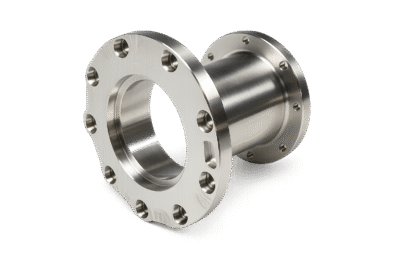

Stainless Steels

While stainless steel may not match aluminum in machinability, it still offers solid machining performance. Its reasonable CNC machining cost makes it a reliable alternative for producing durable components and parts.

Several stainless steel grades are suitable for CNC machining, with some of the most commonly used ones being:

This is one of the most widely used stainless steel grades for CNC machining. It offers excellent weldability and formability.

SS304 is commonly used in the machining of kitchen equipment and household appliances. It’s also a popular choice for producing pipes and machinery used in food processing applications.

The SS303 grade of stainless steel has excellent corrosion resistance and durability. These properties make SS303 ideal for the metal fabrication of gears, shafts, bushings, nuts and bolts, and aircraft fittings.

The 303 stainless steel grade contains 17% chromium, 8% nickel, and 0.15% sulfur. However, this sulfur content makes it impossible to harden this metal through heat treatment.

SS316 is a stainless steel grade known for its exceptional strength and corrosion resistance. Its superior corrosion protection comes from a 2% to 3% molybdenum content, in addition to its chromium and nickel composition.

Thanks to its high strength and reliability, SS316 is widely used in aerospace components and medical implant applications.

Copper

Copper offers outstanding thermal and electrical conductivity, making it a top choice for manufacturing electrical components. While it is a more costly material, it delivers excellent machinability for precision parts.

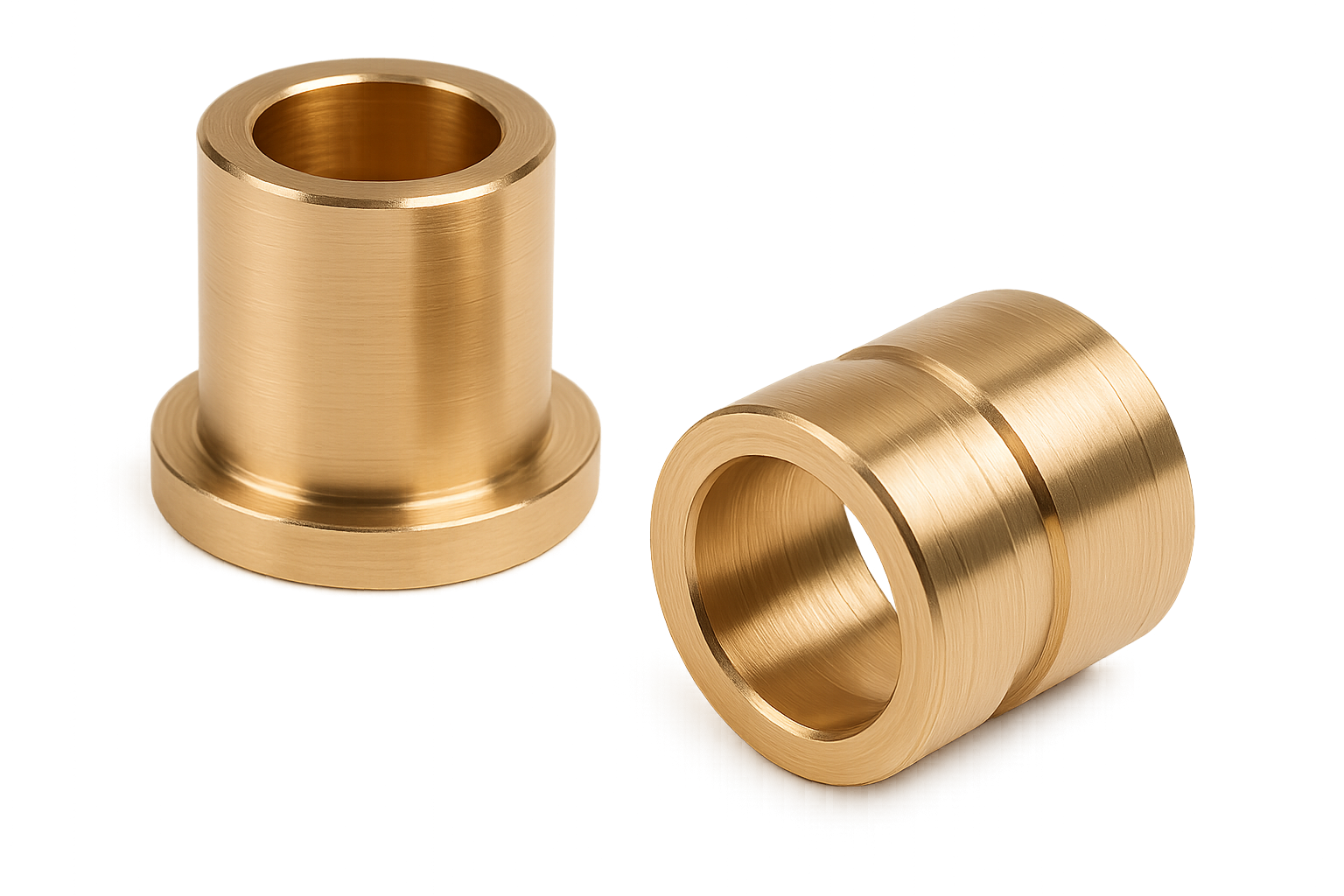

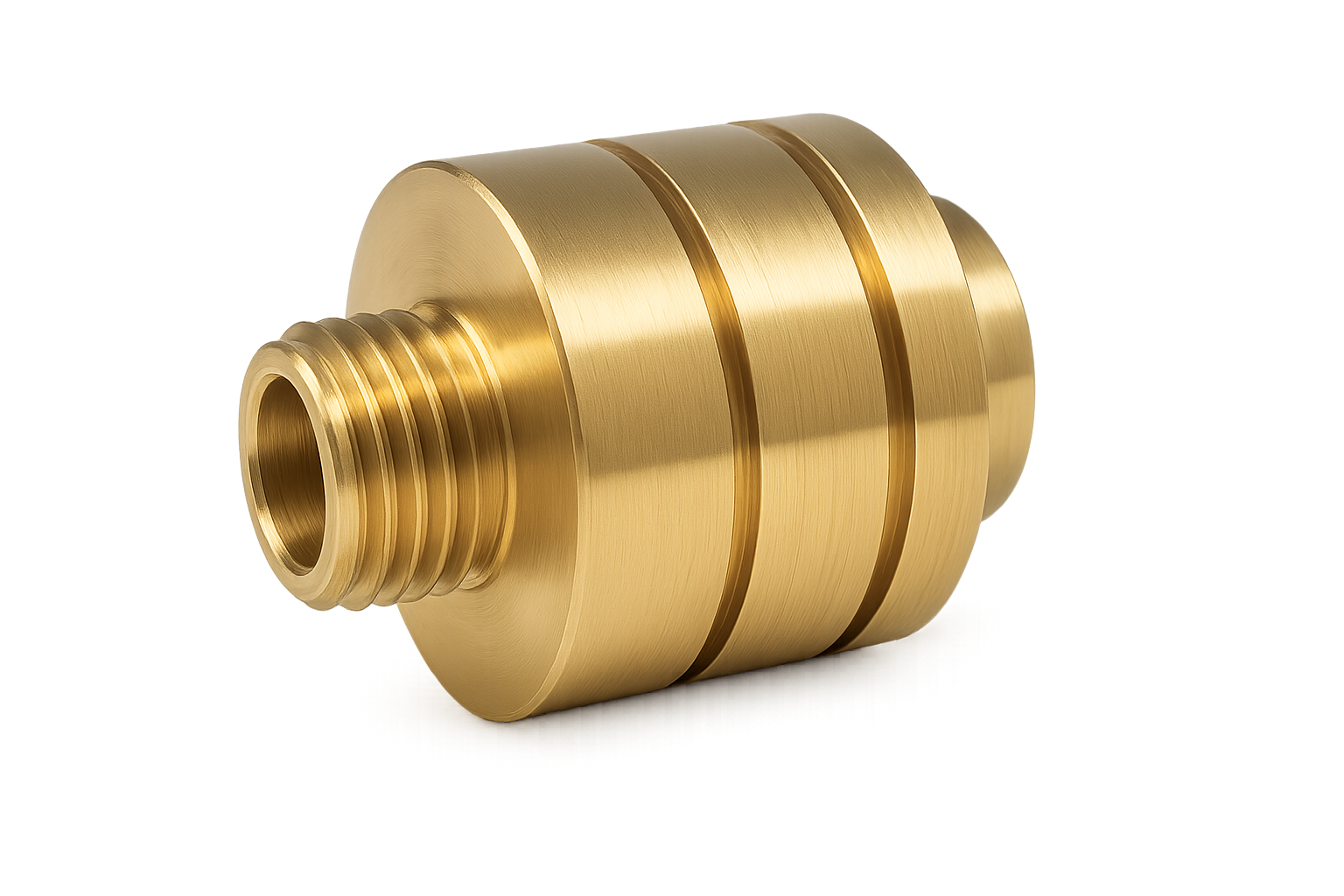

Brass

Brass is an alloy composed of copper and zinc, known for its excellent machinability and solid tensile strength. It also offers impressive thermal and electrical conductivity.

Thanks to its natural resistance to saltwater corrosion and ability to perform well in low-temperature conditions, brass is highly durable. Its excellent workability allows for a smooth, polished finish that enhances its visual appeal.

However, brass has moderate hardness and a relatively high material cost, which can increase overall machining expenses. It is commonly used in the production of electrical components, plumbing fittings, automotive parts, musical instruments, and medical devices.

Titanium

Titanium is a metal known for its outstanding strength-to-weight ratio, along with excellent resistance to heat and chemicals. Its superior strength and biocompatibility make it a top choice for manufacturing medical implants and surgical tools. It’s also widely used in the aerospace sector and premium automotive components.

That said, titanium is a costly raw material, which makes it one of the more expensive metals to machine.

Magnesium

Magnesium’s excellent thermal conductivity and mechanical properties make it one of the most machinable metals for CNC processes. It is also extremely lightweight—around 35% lighter than aluminum—making it a great fit for automotive and aerospace applications.

However, CNC machining magnesium comes with safety concerns, as the material is highly flammable and can ignite even under water, nitrogen, or carbon dioxide environments.

What Key Elements Should You Evaluate When Selecting a Metal for CNC Machining?

Selecting the proper material plays a major role in shaping both the performance and overall cost of the finished part. With the right choice, you can achieve the ideal balance between function, price, and ease of machining. Below are some key points to keep in mind when picking a material for CNC machining:

Machining Speed and Efficiency for CNC Projects

The type of metal selected has a major impact on machining time. Choosing a material with lower machinability will significantly increase the time required to complete the job, unlike a metal like aluminum, which offers high machinability and efficient cutting performance. As machining time increases, so does the overall production cost. Additionally, part complexity plays a key role in determining how long a CNC machine will run. More intricate parts require longer machining cycles compared to simple designs, leading to higher CNC machining expenses.

Material Strength and Operating Conditions for Precision Parts

The intended application of CNC machined parts is a key factor in selecting the right metal. For example, if the component will be exposed to heavy loads or stress, a high-strength metal like alloy steel would be more suitable than a softer metal like copper. Conversely, if you need the strength of steel but want to reduce weight—such as in aerospace manufacturing—then titanium becomes an excellent choice. Furthermore, the operating environment of the part should also influence material selection. Factors like exposure to moisture, chemicals, or extreme temperatures must be considered when choosing the ideal metal for the job.

Surface Finishes and Additional Treatments for Metal CNC Components

The metal you choose also impacts the finishing and post-processing steps required for the machined parts. For example, softer metals or harder metals with lower machinability often leave behind tool marks or burrs that need to be removed through additional processing. While these finishing steps enhance the part’s appearance and surface quality, they also add to the overall machining cost. That’s why understanding the type of finish needed early on can help guide you toward the best material. If a smooth, high-quality finish is essential, a metal with excellent machinability is usually the better choice.

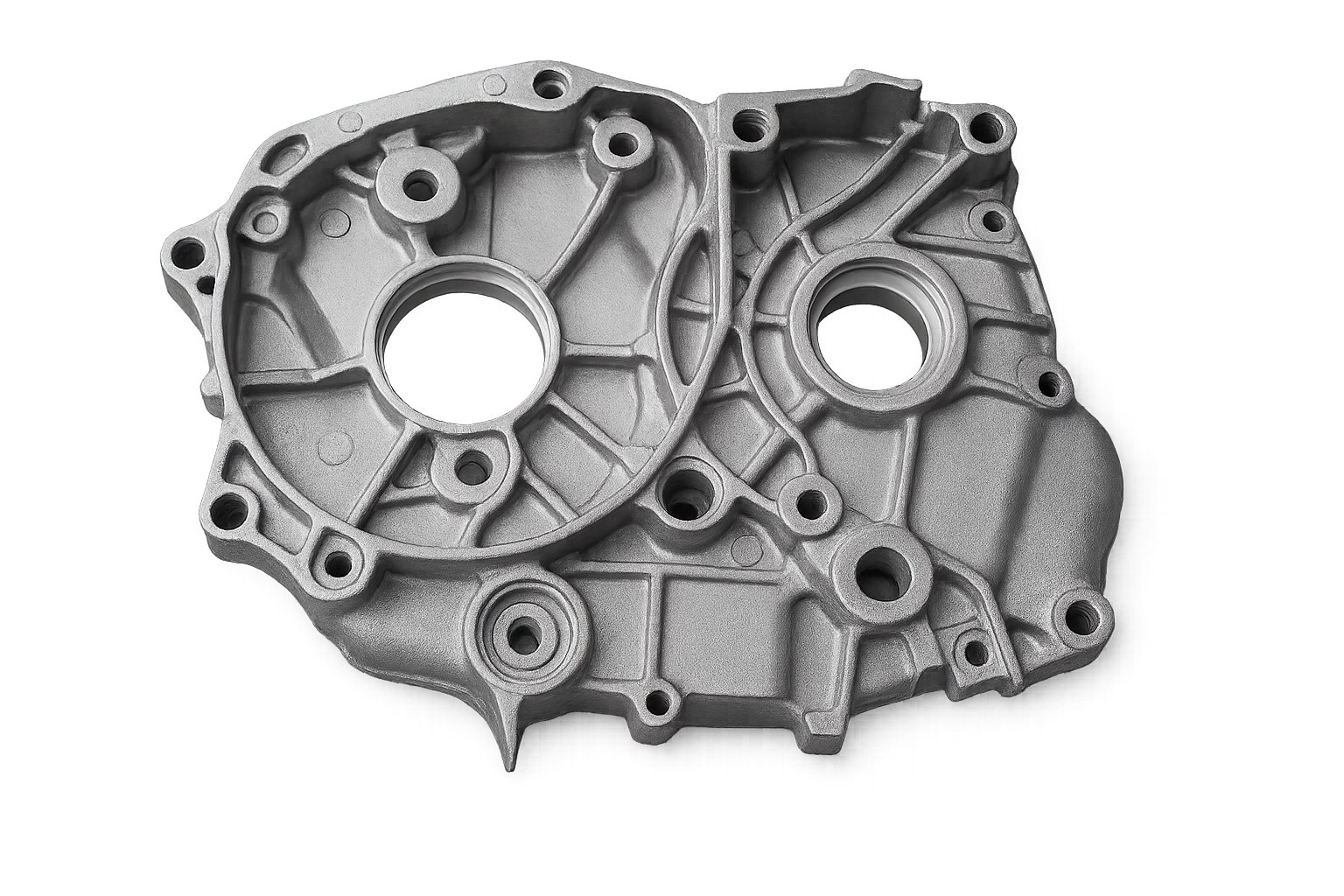

What Types of CNC Machines Can Sochain Precision Use to Machine Metals?

Metal machining requires expert skill and precision, best handled by experienced professionals. Sochain Precision is a leading global provider of high-quality metal CNC machining services, offering both offline and online solutions at competitive prices.

Below are the metal CNC machines we utilize for CNC machining.

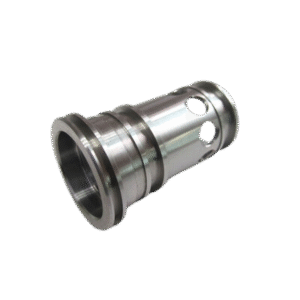

CNC Lathe

This fixed cutting tool is perfect for machining both metal and plastic components. It offers the lowest cost per unit compared to other CNC processes and is highly efficient for producing large volumes of parts.

3 Axis CNC Milling

These CNC milling machines deliver high-precision parts at an affordable cost and are well-suited for components with straightforward geometries.

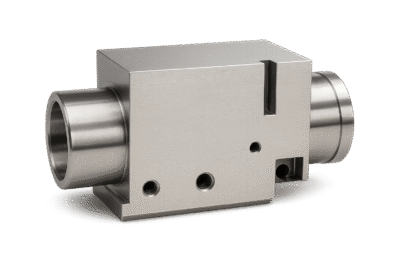

Milling-Turning CNC Center

This machine combines the strengths of CNC milling and turning within one system, enabling the production of complex parts at a lower cost compared to 5-axis machining. It provides exceptional design flexibility and expanded manufacturing capabilities.

Indexed 5-Axis

This machine is capable of producing parts with features that are offset from the primary axis with outstanding precision. However, it comes with a higher machining cost.

Continuous 5-Axis

This is the most advanced and costly machine in our lineup, but it delivers highly accurate, intricate parts with minimal visible machining marks.

Process Options

Process | Relative Cost | Benefits | Limitations |

|---|---|---|---|

CNC Turning (Lathes) | 85% | Manufacture components more affordably than CNC milling Exceptional output capacity for large-scale production | Specialized in producing parts with cylindrical geometries only |

CNC Milling (3-axis) | 100% | More affordable than 5-axis CNC machining.Offers excellent output capacity and flexible design options. | Manual repositioning of components reduces the maximum achievable accuracy. |

Mill-turning CNC centers | 125% | More cost-effective than 5-axis CNC machining. Delivers strong production efficiency and enhanced design flexibility. | Limitations exist due to tool reach and workpiece fixturing design requirements. |

Indexed 5 Axis (3+2 ) | 160% | Removes the need for manual part adjustments. Accurately and efficiently machines features that aren’t aligned with the primary axes. | More expensive compared to traditional 3-axis CNC milling. |

Continuous 5 Axis | 200% | Capable of producing intricate parts with a level of precision unmatched by other methods. Delivers exceptionally smooth, natural-looking surfaces with minimal tool marks. | The most expensive option among all CNC machining processes. |

Frequently Asked Questions

There’s no universal price for metal CNC machining, but there are effective strategies to lower your machining expenses. The total cost is influenced by several elements, including your chosen manufacturing partner and specific project details like tight tolerance requirements and the complexity of CAD designs.

Metal machining involves the production of metal components or products using CNC metal equipment. It is a precise subtractive manufacturing process that shapes raw materials into final parts through controlled cutting. This process makes use of CNC mills, lathes, drilling machines, and other advanced equipment.

You can manufacture a wide range of metal components such as screws, fasteners, and precision parts for industries like automotive, aerospace, and defense. CNC machines also enable the creation of metal artwork through techniques like carving, engraving, and etching.