Plastic CNC Machining

Sochain Precision provides a wide selection of plastics for CNC machining, serving a broad range of industries. Perfect for both single-run prototypes and fully customized end-use components.

- Affordable Pricing

- Quality Material Certifications

- Rapid Lead Times

- Worldwide Shipping

CNC Machining Plastic

Selecting the right plastic for CNC machining requires evaluating several key factors. The material you choose plays a crucial role in the final part’s performance. For instance, the plastic may need to withstand high heat or flex without cracking under stress. Important considerations include chemical resistance, ease of machining, cost, weight, and overall appearance.

ABS

Durable and impact-resistant; simple to machine; widely used for prototyping projects.

POM

Strong and rigid; low friction surface; maintains precise dimensions exceptionally well.

PEEK

Withstands high heat; excellent strength and performance; resistant to harsh chemicals.

Nylon(PA)

Durable and tough; excellent sliding behavior; tends to absorb moisture.

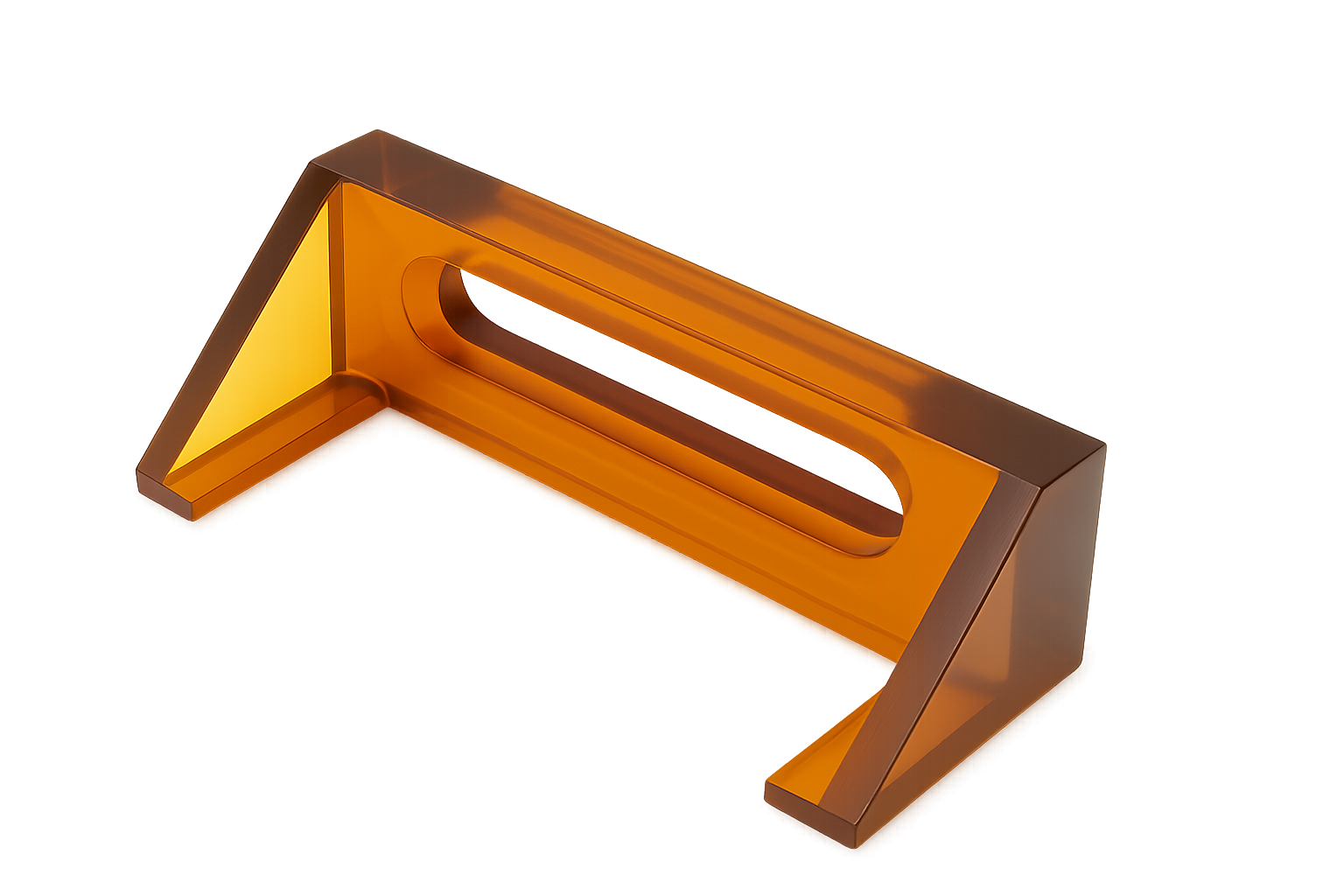

PMMA(Acrylic)

Clear and UV stable; handles outdoor conditions well; prone to brittleness.

PVC

Resistant to chemicals; simple to weld and machine; built for long-term durability.

PTFE(Teflon)

Ultra-low friction; excellent thermal resistance; highly resistant to chemical reactions.

PAI

Outstanding resistance to heat and chemicals; excellent strength and rigidity.

PEI(Ultem)

Strong and heat-resistant; flame-resistant properties; suitable for medical applications.

HDPE

Superior impact strength; minimal moisture absorption; resistant to chemicals.

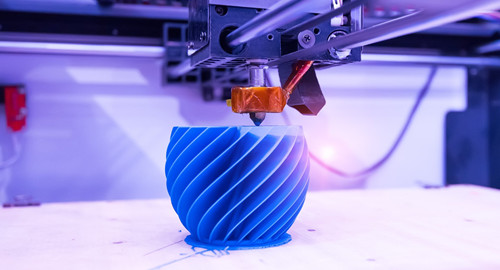

What is Plastic CNC Machining?

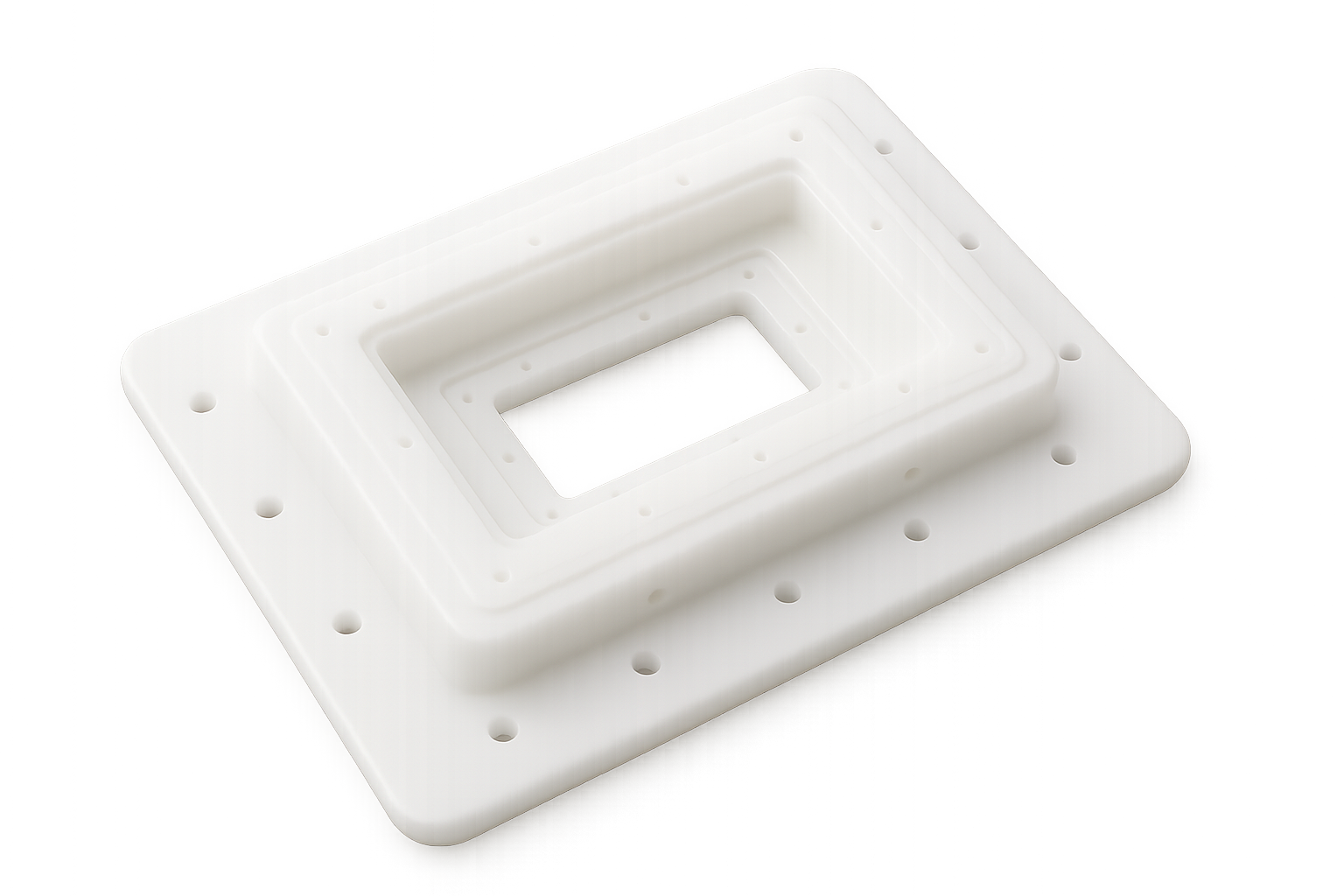

Plastic CNC machining is a subtractive process where a solid plastic block is shaped by a moving cutting tool, which removes material based on a programmed digital design. This ensures the finished part matches the intended shape with precision.

Today, CNC plastic machining is widely used for producing plastic components because it delivers consistent quality, excellent accuracy, and tight tolerance control.

Plastic Machining Process

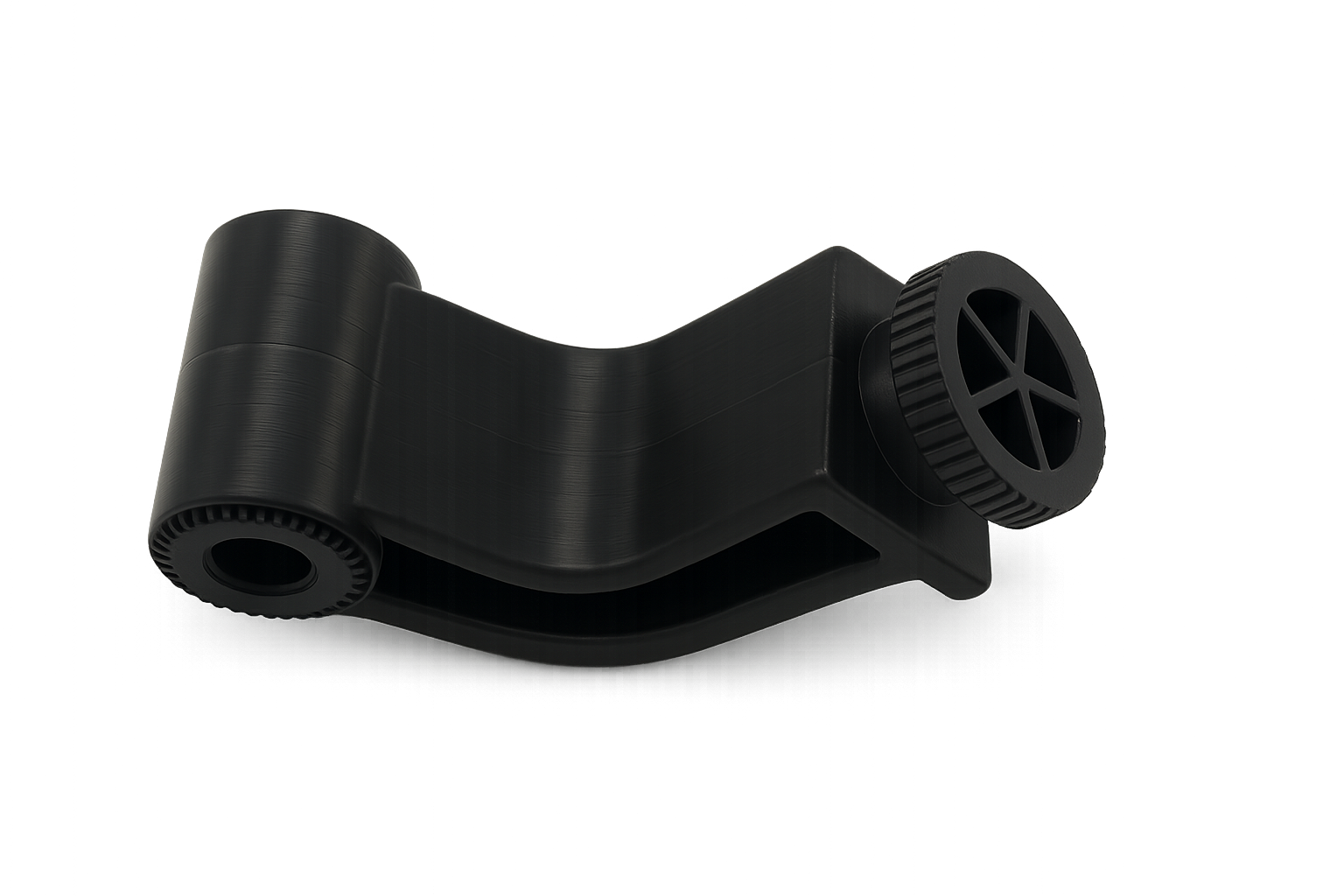

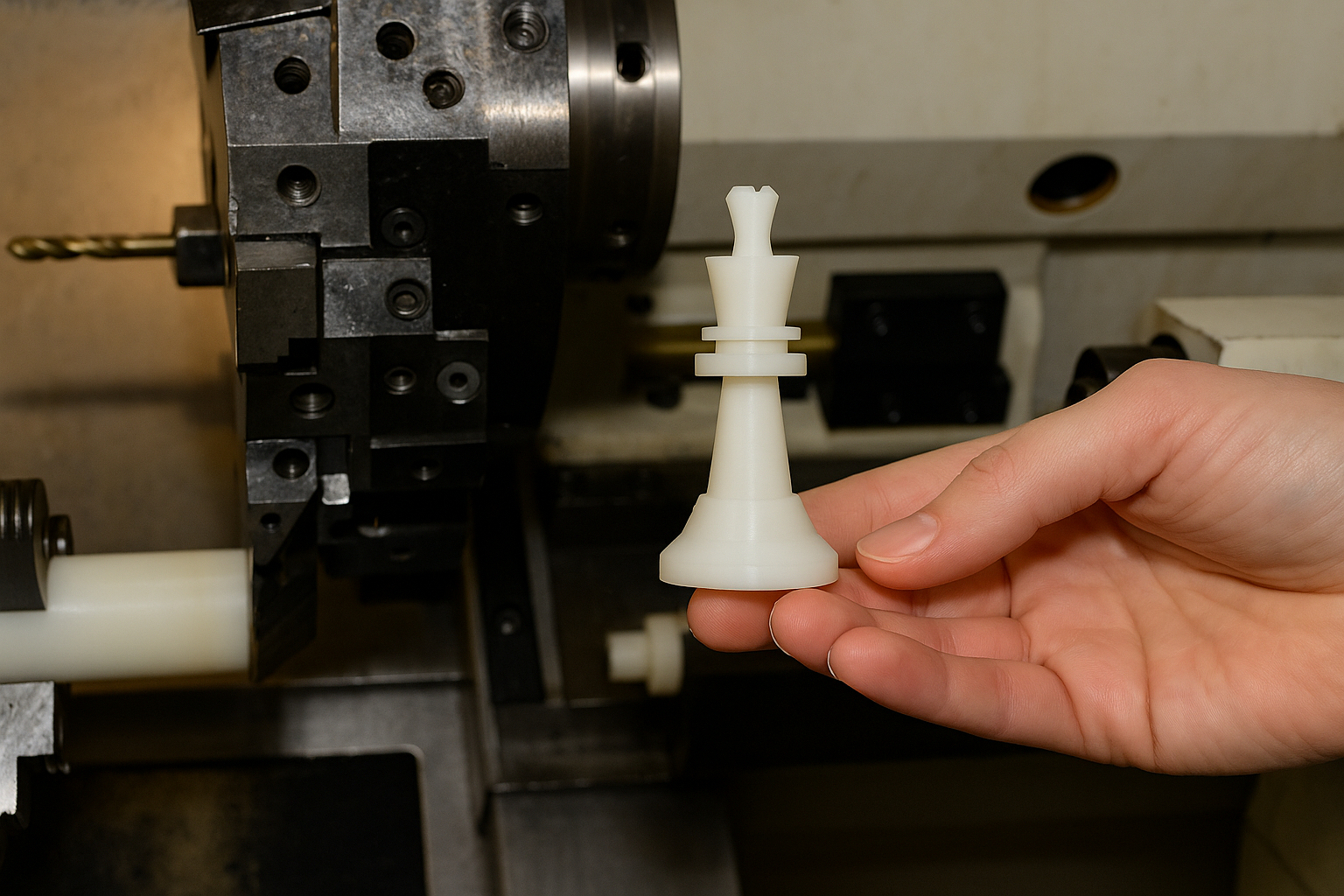

Plastic CNC Turning

Plastic turning is a machining technique where the plastic workpiece rotates while a fixed cutting tool carefully removes excess material to form the part according to the specified design.

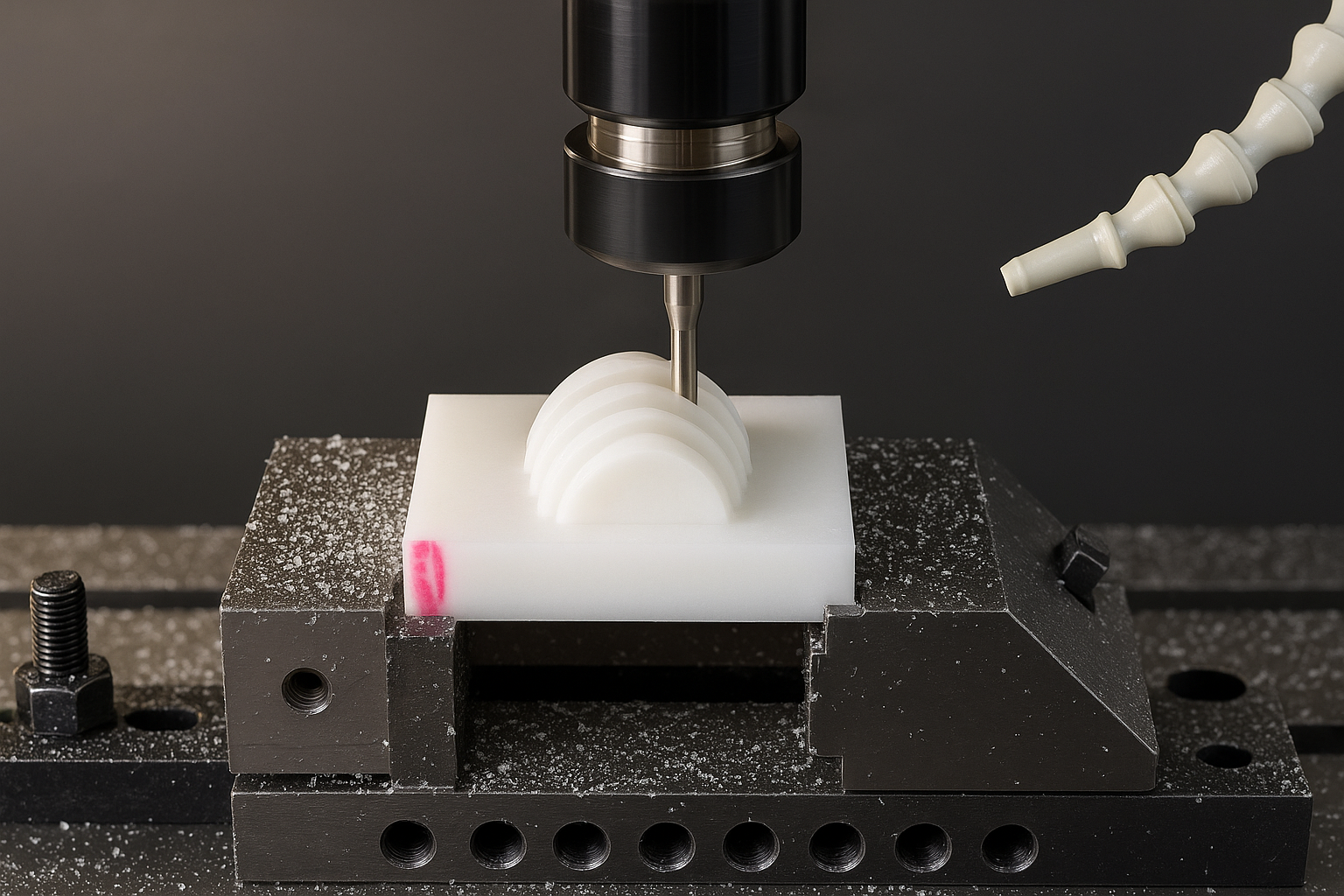

Plastic CNC Milling

Plastic milling is a machining process where the plastic is secured to a table, and a rotating spindle holds the cutting tool, which removes material from various angles to shape the part accurately.

Benefits of CNC Plastic Machining

There are many reasons why manufacturers prefer CNC plastic machining over other plastic fabrication methods. Below are some key benefits of choosing CNC machining for plastic parts.

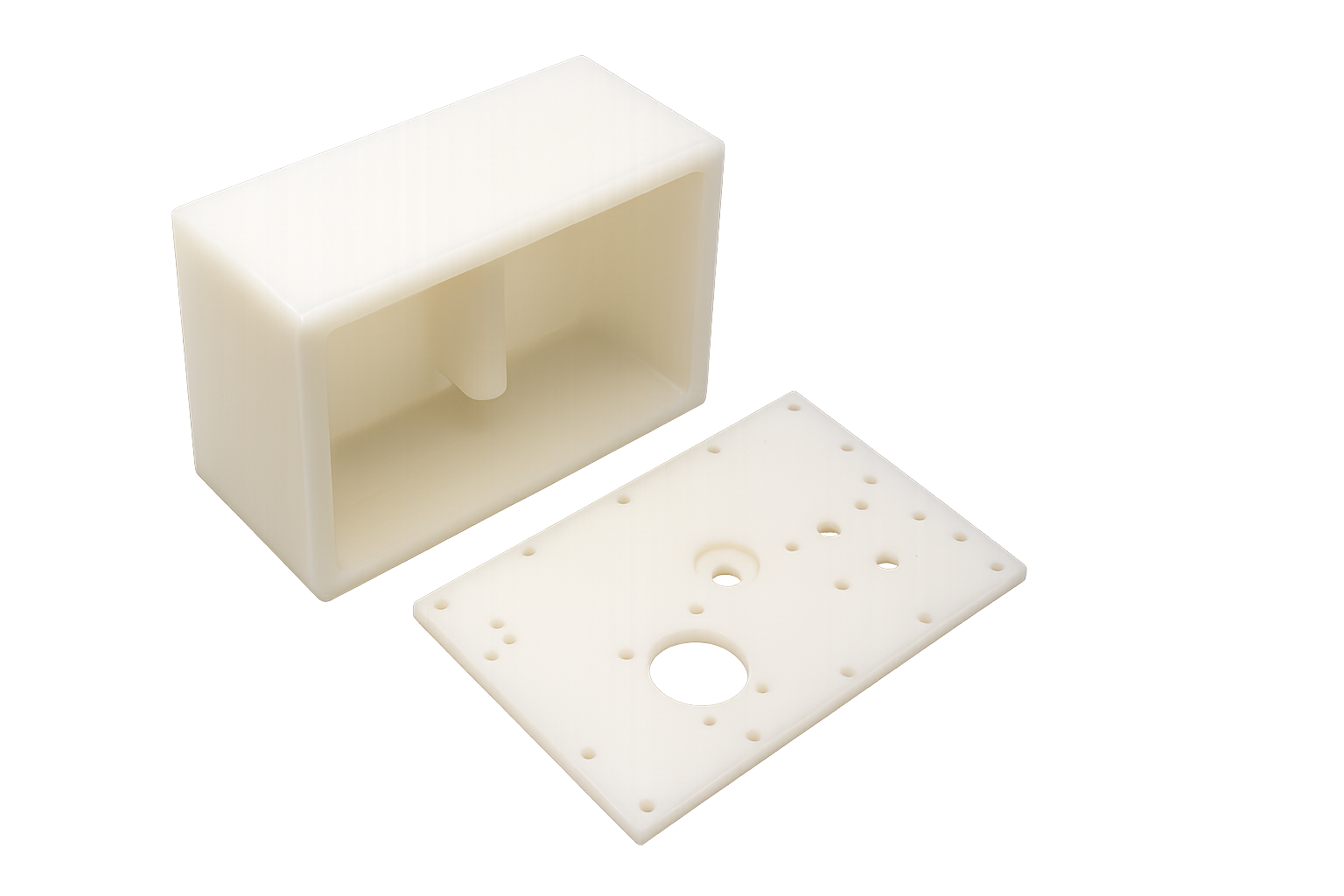

No Mold Required

A major benefit of plastic CNC machining is that it allows parts to be produced without the need for molds, making it perfect for prototyping and low-volume runs. Unlike injection molding, it eliminates the high cost and lead time of metal tooling, resulting in faster turnaround and lower overall expenses.

Greater Dimensional Accuracy

Plastic CNC machining is a great choice for producing parts that demand tight tolerances, delivering higher accuracy and repeatability than injection molding or 3D printing. This makes it especially suitable for precision-focused industries where exact measurements are critical.

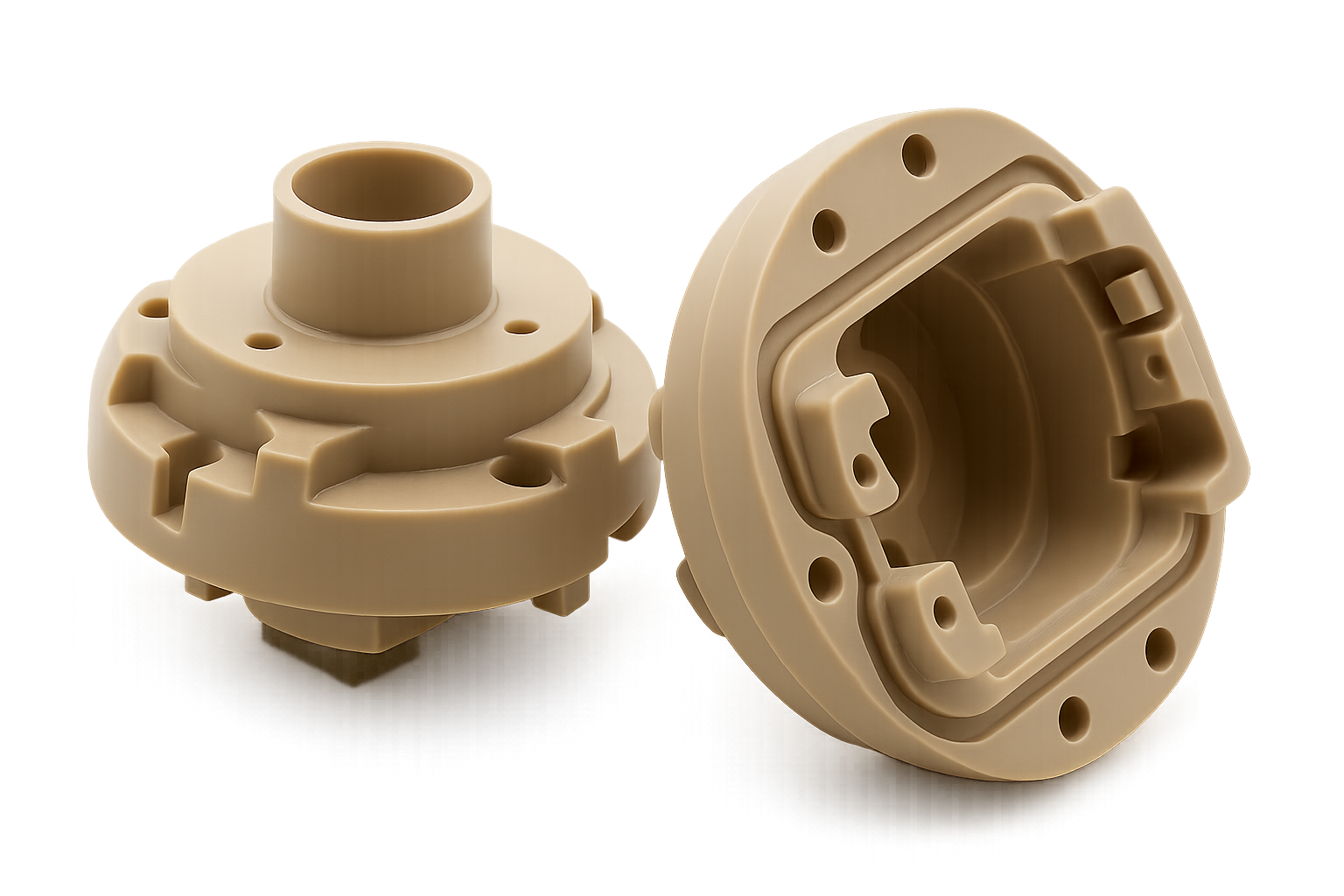

Broader Selection of Machinable Plastics

The outstanding structural characteristics of engineering-grade plastics—such as excellent electrical insulation and a strong strength-to-weight ratio—make them perfect for CNC machining. This allows machinists to work with a broader selection of plastic materials, including commonly used options like HDPE, ABS, Nylon, Acrylic, Delrin, PEEK, and more.

When Should You Choose CNC Machining Over 3D Printing?

For Producing Large Plastic Components

3D printing large plastic parts can be time-consuming, often requiring several hours. In contrast, producing large components with a CNC mill can be done in just minutes.

Material Selection

When designing a part using materials like PVC, POM, PEI, or PEEK, 3D printing isn’t a viable method. Instead, these materials are readily available in block or rod form and are ideal for CNC machining.

Precision Requirements

CNC machining is the preferred method for producing highly accurate parts with complex features, offering precision tolerances as tight as ±0.005mm, whereas 3D printing typically achieves only ±0.1 to 0.5mm.

Complex Part Geometry

When components demand fine details that 3D printing can’t deliver, CNC machining becomes the ideal solution. Features like delicate optical textures can reach radii as small as R 0.05 mm, a level of precision that is challenging for 3D printing to match.

Uses of CNC Machined Plastic Components Across Industries

Medical Devices

CNC machining is widely used to produce high-precision plastic components for the medical field, including parts for drug dispensers, surgical tool handles, and various medical device elements. A broad selection of medical-grade materials is suitable for CNC machining.

Food and Beverage Industry Parts

CNC-machined plastic components are perfect for applications in the food and beverage sector, including the production of seals, nozzles, and valves. These parts are commonly used in food processing and packaging equipment.

Semiconductor Parts

The semiconductor sector depends on plastic CNC machining to manufacture highly accurate components from advanced engineering plastics. These complex parts demand ultra-tight tolerances and excellent surface finishes, which are achievable thanks to the precision of CNC machining.

Automotive and Aerospace Parts

Plastic CNC machining is an excellent method for producing high-performance plastic parts used in the aerospace and automotive sectors. This is because it allows for the precise fabrication of plastics that comply with the stringent standards and specifications required in these industries.

Plastic CNC Machining Services

Need a reliable solution for producing plastic components with tight tolerances and excellent surface finishes?

Sochain Precision delivers advanced CNC machining services with assured quality and quick turnaround times. Backed by over 50 dedicated plastic milling and turning machines, we consistently produce high-precision parts at competitive pricing.

With our capabilities, you can easily place orders for simple or complex prototypes, as well as small to high-volume CNC production runs using a wide range of plastic materials.

Frequently Asked Questions

Plastic CNC machining involves using computer-controlled machines to precisely cut and shape plastic materials into the required design. This method offers exceptional accuracy, making it ideal for creating parts with detailed features and complex geometries.

The price of plastic CNC machining varies based on several factors, such as the type of material and the skill level of the machining service provider or CNC shop. In some cases, the cost can start as low as $10 per hour.

Top plastics for CNC machining include Acetal, PEEK, and PVC, thanks to their excellent machinability and strong dimensional stability.

Also, these different plastics are readily available at a low cost and have the potential to resist chipping and melting. They are also impact-resistant and have high impact strength.