Custom Plastic Injection Molding Services

Receive custom injection molded plastic parts and prototypes with lead times as fast as five business days. We offer professional design-for-manufacturability support. Choose from a wide selection of materials and surface finishes.

Send Your 3D CAD File to Start A New Injection Molding Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

Injection Molding Explain

Injection molding remains the most efficient and economical solution for producing plastic parts in high volumes. The process involves injecting molten plastic into a precision-crafted mold, where it cools and solidifies before being ejected. This cycle repeats rapidly, enabling mass production while spreading the cost of the mold over thousands of units—bringing the per-part cost down significantly. The use of a single mold ensures exceptional consistency in part quality, while also offering unmatched flexibility in materials, colors, finishes, and surface textures compared to CNC machining or 3D printing.

Our custom injection molding service focuses on delivering rapid prototypes and scalable production parts. We prioritize customer needs by matching each project with the most suitable mold manufacturer in our trusted network, ensuring the best results without compromising design intent. Every quote includes expert DFM guidance, and dedicated project managers oversee your order from start to finish. Our team has in-depth experience across all major industries, including specialized expertise in medical-grade injection molding and silicone rubber components.

Custom Plastic Injection Molding Capabilities at Our Factory

| Service | Details |

|---|---|

Lead Time | Lead times as fast as 5 business days, with rapid quote turnaround and expert design-for-manufacturing (DFM) analysis included.Starts at 5 business days, including fast quote responses with design-for-manufacturing (DFM) feedback |

Materials | Wide selection of plastics available, including custom material sourcing and color matching—see the full list of supported materials below. |

Machines Available | Support for single, multi-cavity, and family mold setups; capable of both automated side actions and hand-loaded core inserts. |

Inspection and Certification Options | Includes FAI and PPAP. ISO 9001. |

Tool Ownership | Molds remain customer-owned with full maintenance provided throughout the production lifecycle. |

Mold Cavity Tolerances | ±0.005" accuracy during mold machining, plus an added ±0.002" per inch to account for material shrinkage during molding. |

Part to Part Repeatability | +/- 0.004" or less |

Critical Feature Tolerances | Requests for tighter tolerances are available and may lead to higher tooling costs due to extra sampling and refinement. Our team machines all critical features to a steel-safe state for added precision and flexibility. |

Available Mold Types | We offer both steel and aluminum tooling options, with production mold classes ranging from Class 105 for prototyping to Class 101 for high-volume manufacturing. Our facility commonly produces Class 104, 103, and 102 molds to meet a wide range of production needs. |

This table depicts the general tolerances for Xometry’s plastic injection molding service and accounts for adequate draft, radii, and coring for manufacturability. Learn more about our injection molding manufacturing standards.

Need Fast Delivery on Custom Molds and Parts?

Quick Turn Injection Molding

Receive quotes in as little as 24 hours and get high-quality, domestically produced plastic parts in just 5 business days with our rapid injection molding service.

Sochain Injection Molding Mold Classes

Injection mold tooling is categorized from Class 105 for prototypes to Class 101 for high-volume production. These standardized classifications help align expectations between customers and manufacturers regarding tool durability and production capabilities.

Fewer than 500 shots. Designed solely for prototyping. This mold is built with cost-efficiency in mind to produce a limited number of sample parts. Often referred to as Class V tooling.

Example: a short-run pilot build of 100 units for functional evaluation.

Up to 100,000 shots. Suitable for low-volume production. Best used with non-abrasive resins and limited part complexity. Offers a cost-effective solution for moderate production needs. Commonly referred to as Class IV tooling.

Example: Aluminum or MUD base molds, SPI B-3 surface finish, manual inserts, and small batch repeats.

Up to 500,000 shots. Ideal for medium-volume production. This mold type is widely used for general manufacturing needs and falls within a standard pricing range. Often referred to as Class III tooling.

Example: Aluminum or steel molds, integrated slides or lifters, suitable for recurring production runs of 1,000–5,000 parts.

Designed for medium to high-volume production, this tooling is well-suited for abrasive materials and applications demanding tight tolerances. It offers excellent durability and falls into a higher pricing tier. Also known as Class II molds.

Example: Hardened steel mold with SPI A-2 surface finish, fully automated slide systems, and regular production scheduling.

Exceeding 1,000,000 cycles, these molds are built for ultra-high-volume production. As the most expensive class, they utilize premium materials and advanced construction techniques. Class 101 molds are also referred to as Class I tools.

Example: High-cavity steel molds integrated with fully automated systems and continuous, lights-out manufacturing operations for large-scale part output.

.

Additional Molding Solutions Offered by Our Factory

Insert Molding Service

Create Durable, High-Performance Prototypes and End-Use Components Using Our Insert Molding Capabilities

Overmolding Service

Reliable Manufacturing Solution for Pilot Builds, Small-Batch Production, and Interim Tooling Needs

Medical Injection Molding Service

Premium Injection Molding Services with ISO 13485 Certified Medical Production.

China Injection Molding Service

Top-quality injection molded parts manufactured in China. Simplify your China molding projects with our fully managed service

Liquid Silicone Rubber Molding

Produce custom silicone prototypes and functional production parts in as fast as 15 days, with various durometers and medical or industrial-grade LSR materials. Availability may vary.

Large Part Injection Molding Service

Receive custom plastic injection molded prototypes and production parts in just 10 business days. Our team offers professional DFM analysis. A wide selection of materials and surface finishes is ready for your needs.

Precision Custom Plastic Injection Molding Solutions

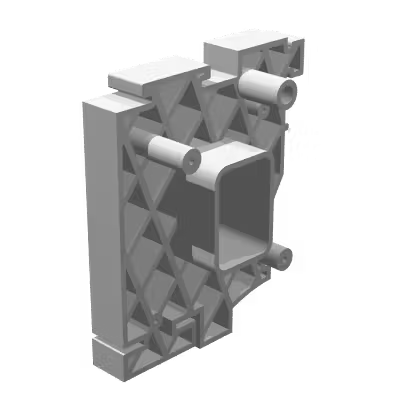

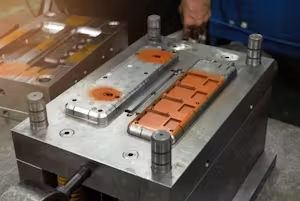

The plastic injection molding process at our facility involves using a precision injection molding machine, high-grade raw plastic material, and a custom-machined mold. The plastic resin is first melted, then injected into a steel or aluminum mold cavity, where it cools and takes the shape of the final part.

At our factory, we begin by carefully evaluating your injection molding request to align your specifications, timeline, and budget. Using your 3D CAD files, we CNC machine a durable, high-performance mold. After initial molding, we provide T1 samples for review and refinement. Once approved, we move into full-scale production. We manufacture a wide range of components, from small precision medical parts to large-scale automotive and aerospace applications.

Rigid Plastic Materials:

Sure! Here's a rewritten version that mirrors the structure and intent of the original, while highlighting your factory's strengths in material capabilities:

Our factory supports a comprehensive portfolio of thermoplastics, engineered for prototyping and volume production across industries. We work with high-performance materials such as ABS, ASA, and CA, commonly used in durable consumer goods and transparent applications. For chemical resistance and outdoor durability, we offer HDPE, LDPE, PVC, and PET, all widely applied in packaging, containers, and structural components.

We handle advanced engineering resins including LCP, PPS, PEEK, and PEI for aerospace, electronics, and high-heat applications. Our facilities are equipped for processing tough blends like PC-ABS, PC-PBT, and PE-PP, ensuring rigidity, impact resistance, and electrical insulation in demanding environments.

For precision molding, we support materials like POM (Delrin), PA 6/6, PBT, and PARA, ideal for gears, housings, and automotive connectors. Flexible and abrasion-resistant options such as TPU, TPO, and PLA are also available for soft-touch components or sustainable product lines.

From standard commercial plastics to high-end specialty polymers, we offer custom sourcing, color matching, and material certification to meet stringent technical requirements for your molded parts.

Elastomer and Rubber Molded Materials:

Manufacturing elastomeric parts at our facility can be achieved through injection molding, transfer molding, or compression molding, depending on your part’s geometry, required material, and expected production volume. Our experienced team is available to help determine the most suitable process based on your specific application and design requirements.

EPDM (ethylene propylene diene monomer rubber)

A high-performance elastomer known for excellent heat resistance, chemical stability, and moisture sealing. Widely used for automotive weather seals, O-rings, gaskets, and electrical insulation.

PEBA (polyether block amide)

A soft, flexible elastomer commonly used in medical tubing, catheters, and cushioning applications. Known for its UV resistance and long-lasting elasticity.

PVC (polyvinyl chloride – Shore A)

A flexible, flame-retardant elastomer used in outdoor applications, safety mats, and protective films. Soft PVC is typically plasticized to enhance its rubber-like feel and resilience.

TPE (thermoplastic elastomer)

A class of versatile materials combining rubber-like behavior with thermoplastic processability. Ideal for grips, seals, and overmolded components across industries.

TPU (thermoplastic polyurethane – Shore A)

Offers high durability and abrasion resistance. Common in flexible tires, sports gear, seals, and wheels, TPU can be engineered with either flexible or rigid properties.

TPV (thermoplastic vulcanizate – Santoprene)

An advanced elastomer that combines temperature tolerance, compression recovery, and elasticity, widely used for automotive seals, grommets, and appliance parts.

LSR (liquid silicone rubber)

Highly flexible and biocompatible, LSR is ideal for medical devices, food-grade products, and high-temperature automotive components. Our factory supports dedicated tooling and processes for LSR molding.

We offer custom elastomer molding services, including online quoting for plastic injection, silicone rubber, and compression molding. If your preferred material isn’t listed in our stock, simply select “Other” on your quote form, and our engineering team will perform a detailed review based on your tolerances, inspection standards, and volume needs.

Custom Injection Mold Finishes

Finish is determined by our mold engineers based on part geometry and draft requirements. Generally, we apply an SPI B-2 or similar finish. Non-cosmetic internal surfaces are usually left as-machined.

We offer a full spectrum of Society of Plastics Industry (SPI) surface finishes, ranging from Grade 3 diamond high gloss to 320-grit low polish. Available options include: SPI A-1, SPI A-2, SPI A-3, SPI B-1, SPI B-2, SPI B-3, SPI C-1, SPI C-2, SPI C-3, SPI D-1, SPI D-2, and SPI D-3.

We provide a variety of textured surface finishes including matte, swirls, lines, and custom patterns. Our standard texture options include MoldTech MT11010, MT11020, and MT11030. Additional texture finishes are available upon request to meet specific design needs.

The VDI 3400 surface finish standard—commonly referred to as the VDI texture—is based on specifications from the Association of German Engineers (VDI). At our facility, this finish is typically achieved through EDM processing, offering a range of fine to coarse matte textures suitable for various industrial applications.

No additional polishing or surface treatments applied. The part will retain visible machining marks from the tooling process.

We are capable of integrating a wide range of standard inserts in both metric and UNF thread sizes.

Apply 2D graphics directly onto 3D components. All designs will be evaluated before production.

Add custom markings such as serial numbers, brand logos, or text directly onto your components.

Our facility is equipped to handle assembly and labeling of molded components. Contact our team to discuss your specific project requirements.

Custom Injection Molding Design Recommendations

| Feature | Tip |

| Undercuts | Minimize undercuts to simplify tooling and lower costs by incorporating pass-through core features during mold design. |

| Wall Thickness | Ensure uniform wall thickness to avoid sink marks and voids. Consistent, thinner walls also help shorten cycle times and lower manufacturing costs. |

| Drafts | Design components with at least a 0.5° draft angle, and consider up to 5° for surfaces requiring medium texture finishes. |

| Ribs/Gussets | Rib features should be designed at 40–60% of the surrounding wall thickness and must include appropriate draft for easy ejection. |

| Bosses | Boss features should maintain a depth of approximately 30% of the adjacent wall thickness and include a 30% edge relief. For added strength, they should be connected to ribs or sidewalls. |

Benefits and Cases of Our Professional Plastic Injection Molding Solutions

Cost-effective molds enable quick-turn injection molding, delivering parts in as little as 10 business days while keeping prices highly competitive.

Custom injection molding is a powerful solution for both low-volume runs of 250 units and full-scale production exceeding 1,000,000 parts. Compared to CNC machining or 3D printing in the same material, injection molded components typically offer superior performance. With the right resin selection, parts can achieve diverse mechanical properties and chemical resistance. Our precision CNC-machined molds are built to tight tolerances and can reliably produce thousands of consistent, highly detailed parts.

Our capabilities include ISO 9001, REACH, RoHS compliance, high-precision applications.

Injection Molding FAQs

Our injection molding services support a diverse array of industries, including automotive, healthcare, industrial equipment, consumer electronics, home appliances, telecommunications, and more.

In our manufacturing process, components are formed within precision molds, then ejected as complete, ready-to-use parts. In contrast, additive manufacturing like 3D printing builds parts layer by layer using techniques such as extrusion or laser fusion.

Once the order is confirmed, our process begins with a thorough review of the statement of work by a senior manufacturing engineer. A dedicated project coordinator is appointed, and the best-fit production partner is selected. A detailed DFM/PEG report is prepared and shared for customer approval. After approval, we proceed with tooling and mold fabrication. T1 samples are then manufactured and sent for validation. Once approved, full-scale production of the remaining parts is carried out.

At our facility, customers retain full ownership of their injection mold tools. Once a production run is completed, the tool is securely stored on-site for future use. Should you wish to have the tool shipped to your location, we can arrange this upon request—shipping and packaging fees will apply. Our engineering team is also available to assist with compatibility checks if you're uncertain about your in-house equipment requirements.

Absolutely, we can run multiple colors within the same order! When processing different colors, a purging fee will be applied to account for material and machine preparation between color changes.

To prepare an accurate quote, we typically need your 3D CAD files (STEP, IGES, etc.), material requirements, desired surface finish, expected volume, and any specific quality or tolerance criteria.

We support a wide range of thermoplastics such as ABS, PP, PC, PA (nylon) and other engineering plastics suitable for durable, high-precision components.

Yes. Our injection molding services accommodate prototype samples up to full production volumes, with scalable processes to meet different batch sizes.

Sochain Plastic Injection Molding Case Studies

CNC Machinist Expertise at Sochain Precision: Delivering High-Accuracy CNC Machining Solutions

What Is Galvanization? Process, Types, Benefits, and Industrial Applications

What Is Computer-Aided Manufacturing (CAM)?

Start Manufacturing Your Custom Parts Now!

Understanding Your Goals, Delivering Your Solutions – We’re Committed to Making CNC Machining Simple and Stress-Free!