Sheet Metal Fabrication Services

Instant quotes for precision sheet metal components | Fast lead times for both prototypes and production runs | Free standard delivery | Global prototype pricing includes all duties

Start A New Sheet Metal Fabrication Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

Sheet Metal Fabrication with Sochain

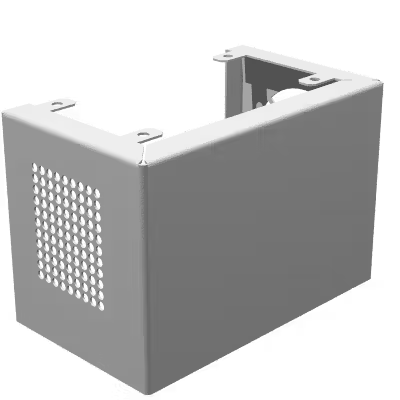

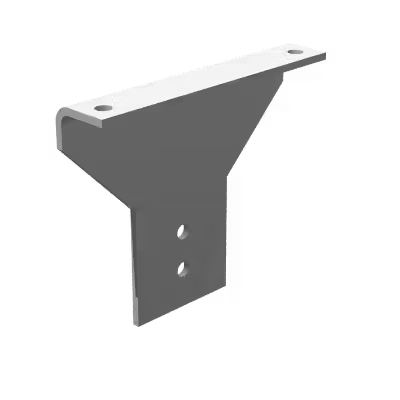

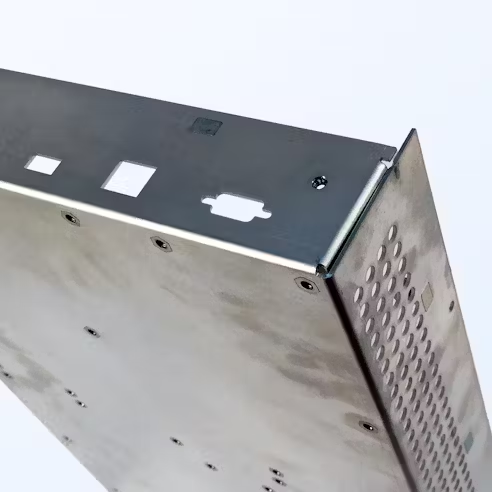

Sheet metal fabrication is a versatile subtractive manufacturing process used to produce durable, high-precision parts from flat metal sheets. It’s widely preferred for components like housings, enclosures, brackets, and structural frames.

Our factory offers rapid and reliable sheet metal fabrication services, transforming your 3D CAD models or technical drawings into functional parts. We work with a wide selection of metals—including aluminum, stainless steel, mild steel, and copper—and provide additional services such as welding, surface treatments, and PEM insert installation. We deliver anything from quick-turn prototypes to large-scale production orders. We offer competitive pricing on small batches and greater cost efficiency on volume runs, with shipping and basic tariffs included in prototype quotes.

Sheet Metal Services Available at Sochain

Laser and Sheet Cutting Services

Instant quotes for laser cutting and waterjet cutting services | No order minimums | Fast turnaround with delivery in just a few days | Free standard shipping for both domestic and international orders | Global prototype pricing includes applicable tariffs.

Custom Online Laser Cutting Service

Premium laser-cut components delivered within days | Complimentary standard shipping for both U.S. and global orders | Global prototype pricing covers all applicable tariffs.

Online Waterjet Cutting Service

Affordable waterjet-cut parts delivered quickly | Free standard shipping for domestic and international orders | Global prototype pricing includes all tariff charges.

Metal Stamping Services

Precision Metal Stamping Solutions From Small Batches To High-Volume Production.

Sochain Sheet Metal Fabrication Capabilities

| Feature | Description |

|---|---|

|

Blank Size |

Our capabilities support sheet sizes up to 5’ x 10’ (1.52 m x 3.05 m), with options for larger part dimensions available upon request. |

|

Standard Lead Time |

6 business days |

|

Sheet Thickness |

Typical material thickness ranges from 0.024” to 0.250”, with support for custom gauges—thicker or thinner—available based on your project requirements. |

|

Tight Tolerances |

Our system supports instant quotes for tolerances down to +/- 0.005". For even tighter tolerances, manual review and approval are available. |

|

Braking (Hydraulic) |

14′ length |

|

Braking (Magnetic) |

Delivers 6 tons of uniform clamping force along the full beam length, with a minimum reverse bend capacity of 5/8". |

|

Punching |

Capable of producing holes up to 2″ in diameter, with larger sizes available upon request. |

|

Welding |

Seamless welded joints, custom weldments, and complete assembly solutions provided in-house. |

Sheet Metal Forming Explain

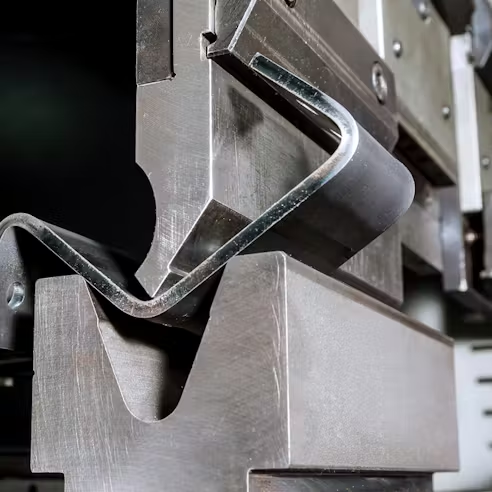

Flat sheet stock is sourced and cut before being shaped into its final form through multiple precision steps. In our typical sheet metal workflow, we begin with blanking—using laser cutting, punching, or waterjet cutting to create detailed internal features and outer profiles.

After blanking, the material is transferred to a press brake station—either manual or CNC-controlled—where die inserts apply precise bends to form the sheet into its required three-dimensional shape. Our forming capabilities support everything from basic brackets to complex geometries requiring custom tooling. Once tooling is set, we offer cost-efficient production for both small batches and large-volume runs, making our sheet metal services ideal for any scale of manufacturing.

How Sochain Sheet Metal Fabrication Works

We make sheet metal fabrication effortless. Simply upload your bent sheet metal drawings to our online quoting platform to get started. Our system quickly generates accurate pricing and lead times—even for complex configurations with tight tolerances down to +/- 0.005", along with options for inserts, welding, and custom finishes. Once your order is placed, we match it with the most suitable partner from our trusted manufacturing network. In just a few days, your custom-fabricated parts will arrive at your doorstep.

With our precise manufacturing capabilities, wide material selection, and robust post-processing services, we support applications across diverse industries, including aerospace, automotive, medical, industrial equipment, consumer products, and more.

Sheet Metal Materials Available at Sochain

Aluminum 1100-H14

Aluminum 5052-H32

Aluminum 6061

Copper 101

Copper C110

Copper C110, H02

Copper 260 (Brass)

Bronze 220

Bronze 510

Stainless steel 301

Stainless steel 304

Stainless Steel 304 #4 brushed

Stainless Steel 304, #8 mirror polish

Stainless steel 316/316L

Stainless Steel 316, #4 brushed

Steel 1018 (Low Carbon)

Steel 1045 (Hot Rolled)

Steel A569/ASTM A1011 (Hot Rolled)

AZ55 Galvalume

A653 Galvanized

1095 Spring Steel

Steel A36

Steel A36, pickled and oiled

Steel A366/1008

Inconel 625

Nickel Alloy 200

Nickel Alloy 400

Titanium (Grade 2)

Titanium 6AI-4V (Grade 5)

Standard Sheet Thicknesses

Available Sheet Metal Finishes

We offer a wide range of material finishes. If your desired material and finish combination isn't listed, simply select “Other” from the finish options and submit your quote with the required specifications, tolerances, inspection criteria, and quantities. Our engineering team will review your submission and provide expert feedback.

Browse our finishing gallery to explore examples of the standard finishes we provide.

Available Sheet Metal Finishes

Only essential post-processing is performed to ensure part functionality and dimensional accuracy.

The surface of the component is finished with a uniform, non-glossy matte texture for a clean and professional look.

Type II (MIL-A-8625/MIL-PRF-8625, Type II) provides a durable, corrosion-resistant coating, ideal for aluminum components. We offer a variety of anodized color options such as clear, black, red, and gold. For enhanced wear resistance, Type III (MIL-A-8625, Type III, Class 1/2 "hardcoat") delivers a thicker, more protective anodized layer while maintaining excellent corrosion resistance.

This sheet metal treatment offers excellent corrosion protection while maintaining good electrical conductivity. It serves well as a paint base and typically results in a gold or yellowish surface. The coating adds minimal thickness—around 0.00001” to 0.00004”. Our chem film finish meets MIL-DTL-5541, TYPE I/II standards.

This is a sheet metal finishing technique where electrostatically applied powder is cured in an oven to form a tough, corrosion- and wear-resistant coating. It offers superior durability compared to traditional liquid painting. A broad selection of colors is available to achieve the desired visual effect. Explore our range of finishes in our powder coating gallery.

A precision sheet metal finishing process that applies a uniform electroless nickel coating to enhance resistance against corrosion, wear, and oxidation—even on complex geometries. This treatment results in a brighter appearance and typically starts at a thickness of 0.0001", conforming to MIL-C-26074 standards.

Gold plating ensures outstanding resistance to corrosion and tarnishing while offering superior solderability. Our standard process follows MIL-G-45204 and ASTM B488 specifications, CLASS 00, 0, or 1, with plating thickness ranging from 0.00002" to 0.00005".

Silver plating provides excellent electrical conductivity and solderability, making it ideal for electronic applications. While prone to tarnishing, it conforms to AMS QQ-S-365D standards with a typical thickness ranging from 0.00002” to 0.0003”.

Sheet Metal Design Guidelines

| Feature | Description (MT = Material Thickness) |

|---|---|

Minimum Bend | 1X MT |

Minimum Hole to Edge Distance | 2X MT |

Minimum Hole to Hole Distance | 6X MT |

Minimum Bend Edge to Hole Distance | 6X MT |

Minimum Feature to Countersink Distance | 8X MT |

Minimum Countersink Depth | 0.6X MT |

Relief Cuts | 1X MT |

Corner Fillets | 0.5X MT |

Cases and Benefits of Our Sheet Metal Fabrication Services

Rapid Tooling

Our facility can efficiently process sheet metal into precise 2D profiles and form them from a wide selection of durable materials, making it ideal for fast and flexible prototyping or tooling applications.

Rapid Prototyping

Offering lead times as short as 6 days, no minimum quantity requirements, and cost-effective pricing per part, our sheet metal service is an excellent choice for rapid prototyping.

End-Use Production

As production volumes increase, per-unit pricing drops considerably. When paired with durable materials and fast turnaround times, our sheet metal fabrication process stands out as a reliable production solution.

Ready to Request a Custom Sheet Metal Quote?

Complimentary delivery provided for all domestic sheet metal fabrication orders.

Why Chosse Sochain Sheet Metal Fabrication Services?

Wide Material Selection

Select from a vast range of material types, surface treatments, precision tolerances, part labeling, and quality certifications to meet your custom sheet metal fabrication needs.

Seamless Ordering

Receive your custom parts directly at your doorstep—no need to worry about vendor sourcing, order coordination, freight handling, or delivery logistics.

Reliable Supplier Network

We hold certifications in ISO 9001:2015. Our supplier network is carefully vetted, with only the most qualified manufacturers passing our strict onboarding standards.

FAQs

We provide laser cutting, punching, bending, forming, welding, stamping, and assembly to produce precise sheet metal components.

We work with a variety of sheet metals including steel, stainless steel, aluminum, brass, and copper alloys to meet structural and functional requirements.

Our equipment supports a broad range of thicknesses, from thin gauge sheet metal to thicker plate materials, depending on the design and application.

Yes. We can produce both prototype samples and low-volume or full production batches based on your project needs.

Yes. In addition to fabrication, we offer welding, hardware insertion, sub-assembly, and finishing services to deliver ready-to-use parts.

We offer finishing options including powder coating, painting, anodizing, plating, deburring, and passivation to enhance appearance and corrosion resistance.

We use precision forming equipment, controlled bending processes, and in-process inspection to ensure flatness, bend accuracy, and dimensional repeatability.

Yes. Our engineering team can review your design and recommend DFM improvements, cost-saving suggestions, and better fabrication strategies before production.

Sochain Plastic Injection Molding Case Studies

CNC Machinist Expertise at Sochain Precision: Delivering High-Accuracy CNC Machining Solutions

What Is Galvanization? Process, Types, Benefits, and Industrial Applications

What Is Computer-Aided Manufacturing (CAM)?

Begin Production of Your Custom Components Today!

Focusing on Your Needs, Providing Precise Results – We’re Dedicated to Making Custom Manufacturing Efficient and Hassle-Free!