Edge treatments play a critical role in modern manufacturing. Whether in CNC machining, metal fabrication, woodworking, or additive manufacturing, the way an edge is finished can directly affect safety, assembly, structural integrity, cost, and aesthetics. Among the most common edge treatments are bevels and chamfers.

Although these two terms are often used interchangeably, bevels and chamfers serve different geometric, mechanical, and functional purposes. Understanding their differences is essential for designers, engineers, and manufacturers aiming to optimize performance and control production costs.

This article provides an in-depth explanation of what bevels and chamfers are, how they differ, where they are applied, and how to choose the right option for your part design.

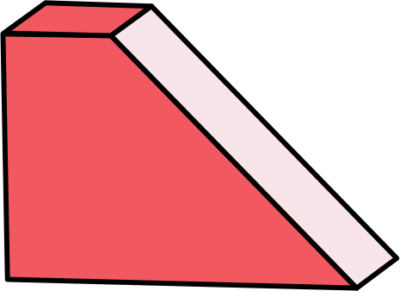

What Is a Bevel?

A bevel is an edge that is cut at an angle other than 90 degrees relative to the surface of the part. Unlike chamfers, bevels offer flexibility in angle selection, allowing designers to specify custom angles based on functional or structural requirements.

Bevels are commonly produced using milling, grinding, or cutting operations and are widely used where load transition, welding preparation, or visual enhancement is required.

Key Characteristics of Bevels

Sloped edge with variable angles (e.g., 30°, 45°, 60°)

Can extend along long edges or surfaces

Often used to increase contact area or improve joint strength

Suitable for both functional and decorative purposes

Common Applications of Bevels

Structural steel and welded joints

Sheet metal fabrication

Decorative furniture and glass edges

Picture frames and architectural elements

Types of Bevels in Machining

Simple Bevel – A single angled cut on one edge

Double Bevel – Angled cuts on both sides of the edge

Compound Bevel – Bevels cut at multiple angles, often for complex assemblies

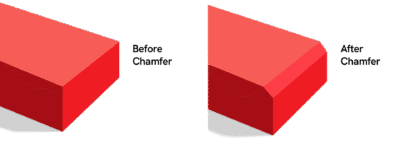

What Is a Chamfer?

A chamfer is a flat, angled surface created by cutting away the sharp corner between two perpendicular faces. Chamfers are most commonly cut at a 45-degree angle, although other angles may be used when required by design.

Chamfering is one of the most widely applied edge treatments in machining because it improves safety, assembly ease, and part quality.

Purpose of Chamfering

Removes sharp edges and burrs

Facilitates part insertion and alignment

Prevents damage during assembly

Improves surface finish and appearance

Types of Chamfers

Inner Chamfer

Located on the inside edge of holes or cavities

Helps guide shafts, fasteners, or bearings during insertion

Outer Chamfer

Applied to external edges

Reduces sharp corners and improves handling safety

Chamfer Configurations

Single chamfer

Double chamfer

Triple chamfer

When combined, inner and outer chamfers create smooth transitions that improve both functionality and aesthetics.

Functions of Chamfering

Chamfering serves multiple mechanical and practical purposes:

Safety: Eliminates sharp edges that can cause injury

Assembly Guidance: Helps align mating parts

Burr Removal: Cleans up machining residues

Stress Reduction: Minimizes stress concentration at edges

Heat Treatment Preparation: Chamfers are often required before heat treatment to prevent cracking and deformation

In many engineering drawings, chamfers are specified not for appearance but as a mandatory requirement for proper installation and long-term reliability.

Importance of Chamfers in Agricultural Machined Parts

Agricultural machinery operates under heavy loads, vibration, dirt, and environmental exposure. Chamfers play a crucial role in:

Reducing stress concentrations on shafts and housings

Preventing crack initiation

Improving assembly efficiency in field conditions

Poorly maintained or worn chamfers can lead to:

Difficult assembly

Increased mechanical stress

Reduced equipment lifespan

Routine inspection and maintenance of chamfered edges are therefore essential in agricultural equipment.

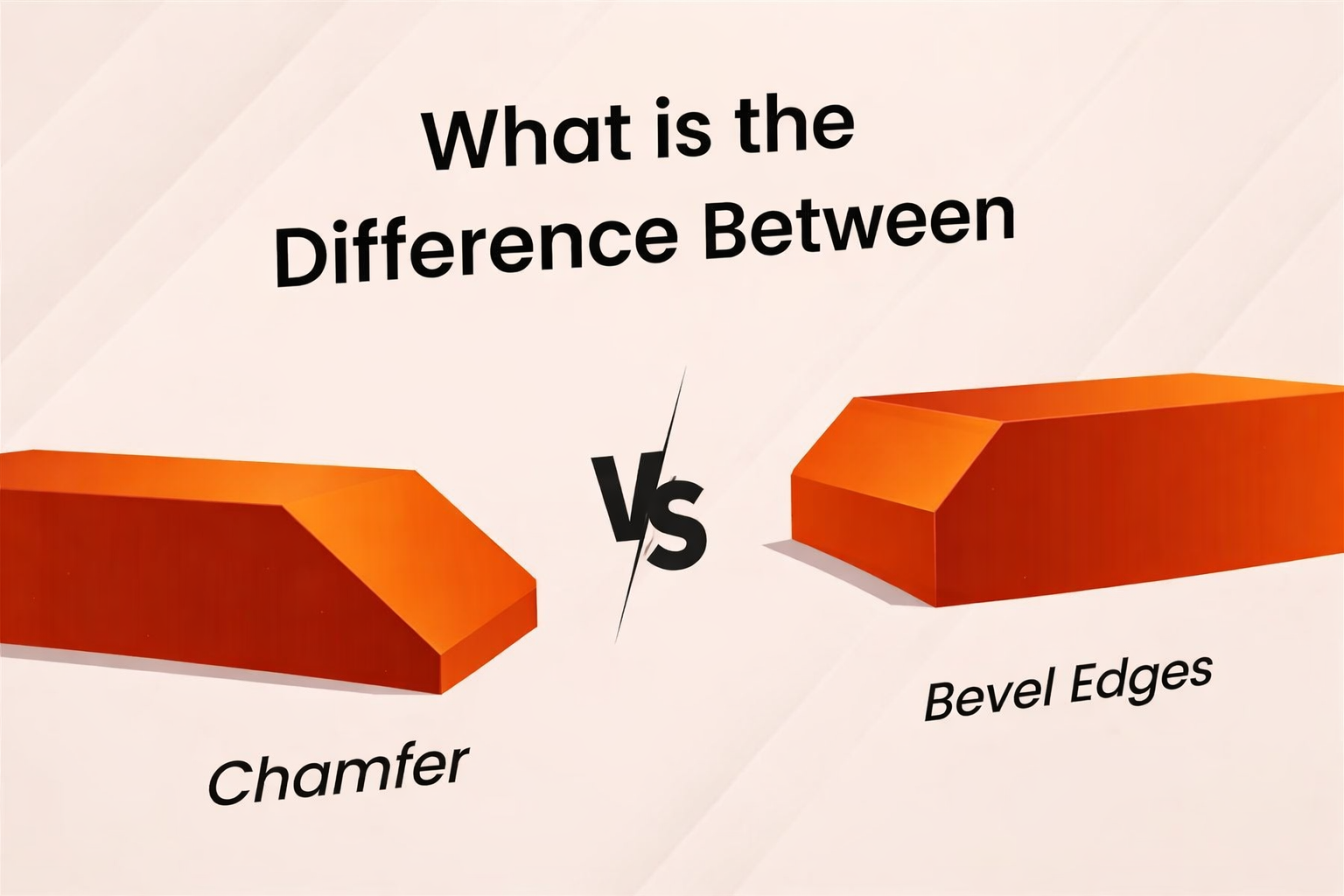

Bevel vs. Chamfer: Key Differences Explained

In mechanical design and manufacturing, bevels and chamfers are both edge treatments used to remove sharp corners. While they may appear similar at first glance, they serve different functional, structural, and manufacturing purposes. Understanding the distinction is critical for proper design intent, cost control, and part performance.

Core Difference Between Bevel and Chamfer

The primary difference lies in purpose and scale:

A chamfer is typically a small, functional edge break, most commonly at 45°, used to improve assembly, reduce burrs, and eliminate sharp edges.

A bevel is generally a larger, angled surface, often with non-45° angles, designed for structural engagement, load transfer, or welding preparation.

In short:

Chamfers support assembly and safety, while bevels support strength and structural function.

Design Intent: Functional vs. Structural

From a design perspective:

Chamfers are applied when:

Parts must align or insert smoothly

Sharp edges pose handling or safety risks

Dimensional accuracy at the edge is important

Bevels are applied when:

Edges must engage under load

Weld penetration or joint strength is required

Parts must interface at an angle

Misusing one in place of the other can lead to assembly issues, excessive machining cost, or reduced mechanical performance.

Machining and Cost Implications

Manufacturing impact is another major differentiator:

Chamfers

Easy to machine

Short cycle time

Minimal tool wear

Tight tolerances achievable

Bevels

Longer tool engagement

Often require angular control or multi-axis machining

Higher cycle time and inspection effort

As a result, chamfers are preferred in high-volume production, while bevels are reserved for function-critical features.

Tolerances and Inspection

Chamfers usually allow simple linear inspection and can hold tight tolerances.

Bevels often require angular measurement, increasing inspection complexity.

Designers should specify bevel tolerances only when functionally necessary, as over-specification increases cost without added value.

Application Comparison

| Aspect | Chamfer | Bevel |

| Typical Angle | 45° | 30°–60° (or custom) |

| Primary Purpose | Assembly & safety | Strength & structural function |

| Size | Small | Larger |

| Machining Cost | Low | Higher |

| Common Uses | Lead-ins, edge breaks | Welding, load-bearing joints |

Choosing the Right Edge Treatment

Use a chamfer when you need:

Smooth assembly

Reduced burrs

Lower cost and faster production

Use a bevel when you need:

Improved weld quality

Load distribution

Structural reliability

Practical Example: Helical Grooving on Slip Rings

In helical grooving on slip rings, chamfers are applied along groove edges to:

Reduce brush wear

Maintain smooth electrical contact

Improve operational stability

Typical Specifications:

Chamfer angle: 45°

Tolerance: ±0.005 mm

Surface finish: Ra 0.4 µm

Materials: Copper or brass

In some designs, a bevel may be used on one side while a chamfer is applied on the opposite edge to balance functionality and wear resistance.

Visual Comparison of Chamfer vs. Bevel

Chamfer Characteristics

Consistent angle

Flat transition surface

Common in safety and functional applications

Bevel Characteristics

Variable angles

Sloped transition

Common in welding and decorative designs

Applications of Chamfer and Bevel

Chamfer Applications

CNC machining (shafts, gears, engine parts)

Automotive and aerospace components

Furniture edges and cabinetry

Dental implants and medical devices

Bevel Applications

Structural steel (I-beams, H-beams)

Decorative glass and furniture

Sheet metal and fabrication work

Architectural and construction components

Cost Considerations of Adding Bevels and Chamfers

While bevels and chamfers improve usability and appearance, they also increase machining time and cost. Each additional edge treatment requires:

Extra machine operations

Tool wear

Inspection and quality control

If a chamfer or bevel does not serve a clear functional purpose, it may be unnecessary.

Factors Affecting Chamfer and Bevel Cost

Part Complexity – Complex geometries increase machining time

Material Hardness – Harder materials raise tool wear and cost

Tolerance Requirements – Tighter tolerances increase inspection effort

Machining Method – Milling, turning, and grinding vary in cost

Production Volume – Higher volumes reduce per-part cost

Cost-Reduction Strategies

Use countersinks instead of decorative chamfers

Apply chamfers only where functionally required

Allow larger tolerances where possible

Use general drawing notes such as “Remove all sharp edges”

Avoid modeling non-critical chamfers in CAD files

Smart design-for-manufacturing (DFM) decisions can significantly reduce cost without sacrificing performance.

Choosing Between Chamfer and Bevel

Choose a chamfer when:

Assembly guidance is required

Stress concentration must be reduced

Safety is a priority

Choose a bevel when:

Welding strength is required

Aesthetic appearance matters

Large angled surfaces are needed

The decision should balance function, cost, manufacturability, and appearance.

Selecting the Right Machining Partner

An experienced machining partner can:

Recommend optimal edge treatments

Balance cost and performance

Ensure compliance with industry standards

Choosing a supplier with strong engineering expertise ensures better design outcomes and reduced production risk.

Conclusion

Bevels and chamfers may seem like small design features, but they have a significant impact on performance, safety, and manufacturing cost. By understanding their differences and applications, engineers and designers can make informed decisions that improve part quality and efficiency.

Consulting a professional machining company early in the design phase allows for optimized edge treatments, reduced costs, and improved product reliability. Contact Sochain Precision for more information.

FAQs

1. When should a chamfer be specified instead of a fillet?

A chamfer should be specified when precise edge control, ease of assembly, or clearance for mating parts is required. Chamfers are easier to machine than fillets, allow tighter dimensional control, and are preferred for press fits, bearing installation, and shaft insertion. Fillets, while excellent for stress reduction, require additional tooling and machining time.

2. How do chamfers and bevels affect stress concentration?

Chamfers reduce stress concentration by removing sharp 90-degree corners, distributing loads more evenly across an edge. Bevels can further reduce stress by increasing load transfer area, especially in welded joints. However, excessively large bevels may introduce stress risers if not properly designed.

3. What tolerances are typically achievable for chamfers and bevels in CNC machining?

Chamfers: Tight tolerances of ±0.005 mm are achievable on precision CNC equipment.

Bevels: Generally allow looser tolerances (±0.010 mm or greater) due to larger surface area and angular variation.

Tolerance selection should be driven by functional requirements rather than aesthetics.

4. How should chamfers and bevels be dimensioned on engineering drawings?

Chamfers are commonly specified using:

Angle × length format (e.g., C1 × 45°)

Two linear dimensions

Bevels are typically defined by:

Angle and depth

Reference surfaces for angular control

Clear and unambiguous dimensioning reduces machining errors and inspection time.

5. Do chamfers and bevels impact tool wear and machining time?

Yes. Chamfers are generally fast and low-impact on tool wear, especially when cut with standard chamfer tools. Bevels often require longer tool engagement, multi-axis machining, or tool repositioning, increasing cycle time and tool wear—particularly in hardened materials.

6. Are chamfers required before heat treatment?

In many cases, yes. Chamfers help relieve stress and prevent crack initiation during heat treatment processes such as quenching. Sharp edges are more prone to cracking and deformation under thermal stress, making chamfering a recommended or mandatory pre-treatment step.

7. How do bevels improve weld quality?

Bevels create a larger weld groove, allowing better penetration and fusion of filler material. This results in:

Stronger joints

Reduced risk of incomplete fusion

Improved fatigue resistance

Common welding bevel angles range from 30° to 60°, depending on material thickness and welding method.

8. When is it acceptable to replace modeled chamfers with a general note?

If chamfers are non-critical to part function, designers can remove them from the 3D CAD model and instead add a note such as “Break all sharp edges”. This approach reduces programming time, simplifies machining, and lowers cost without compromising safety.

9. How do material properties influence chamfer and bevel design?

Harder materials (e.g., tool steel, stainless steel) increase tool wear and machining cost. In such cases:

Smaller chamfers are preferred

Larger bevels should be avoided unless functionally required

Softer materials (e.g., aluminum, brass) allow greater flexibility in edge design with lower cost impact.

10. Can chamfers and bevels affect dimensional inspection?

Yes. Tighter chamfer tolerances require additional inspection steps, often using optical measurement or CMM equipment. Bevels may require angular inspection, which increases inspection complexity. Designers should balance tolerance tightness with actual functional necessity.

11. How do chamfers improve assembly automation?

Chamfers act as lead-in features, guiding parts into position during automated assembly. This reduces:

Misalignment

Part jamming

Cycle time

For robotic or high-speed assembly lines, chamfers are often essential.

12. What is the most cost-effective edge treatment for high-volume production?

For high-volume parts, simple chamfers with generous tolerances offer the best balance of safety, functionality, and cost. Decorative bevels or compound edge treatments should be avoided unless they serve a critical mechanical or structural purpose.