Galvanization is widely used and cost-effective corrosion protection methods in manufacturing. From large-scale infrastructure and automotive production to CNC-machined components and sheet metal parts, galvanization plays a critical role in extending service life, reducing maintenance costs, and improving long-term reliability.

As global demand for durable steel components continues to grow, understanding how galvanization works—and which method is best for your application—has become essential for engineers, designers, and procurement teams alike.

This guide provides a comprehensive, engineering-level explanation of galvanization, covering its principles, processes, methods, advantages, limitations, and real-world applications, while helping you make informed material and surface-treatment decisions.

What Is Galvanization?

Galvanization is a surface treatment process that applies a protective zinc coating to steel or iron to prevent corrosion. Zinc serves two critical functions:

Barrier Protection – It physically isolates the base metal from moisture, oxygen, and corrosive chemicals.

Sacrificial Protection – Zinc corrodes preferentially, protecting the steel even if the coating is damaged.

Unlike paint or organic coatings, galvanization forms a metallurgical bond with the base metal, making it significantly more durable and long-lasting under mechanical stress and outdoor exposure.

Although steel is the most commonly galvanized material, iron and certain iron-based alloys can also be treated using zinc-based processes.

A Brief History of Galvanization

The concept of galvanization dates back to the 18th century and is named after Luigi Galvani, whose work on electrochemical reactions laid the foundation for understanding galvanic corrosion.

Key historical milestones include:

1836: Stanislas Sorel patents the modern hot-dip galvanizing process in France

1837: William Crawford patents the process in the UK

Mid-19th century: Rapid adoption in roofing, infrastructure, and industrial manufacturing

By 1850, zinc consumption for galvanization exceeded 10,000 tons annually, marking the beginning of large-scale industrial use. Today, galvanization remains a cornerstone technology across construction, automotive, energy, and manufacturing sectors.

How Does Galvanization Work?

At its core, galvanization relies on electrochemical principles. When steel is coated with zinc, the zinc acts as an anode, while the steel becomes the cathode.

When exposed to moisture or electrolytes:

Zinc oxidizes first

Steel remains protected

A stable zinc carbonate patina forms over time, further slowing corrosion

This means galvanized steel continues to resist rust even when scratched or cut, a key advantage over paint-based coatings.

Chemical Principles Behind Galvanization

Galvanization exploits galvanic corrosion, where two dissimilar metals are electrically connected in a corrosive environment.

Zinc has a lower electrode potential than iron

Zinc sacrifices itself to protect steel

Corrosion products form a dense, insoluble protective layer

This self-healing behavior is what makes galvanization especially valuable in outdoor, marine, and industrial environments.

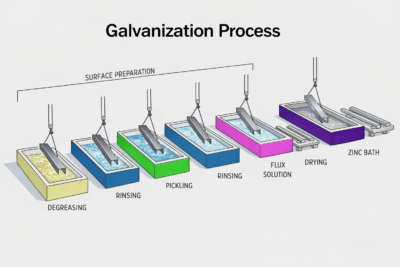

Steps of the Galvanization Process

A high-quality galvanized coating depends on precise process control across multiple stages:

Degreasing & Cleaning – Removes oils, dirt, and organic contaminants

Pickling – Acid bath removes rust and mill scale

Rinsing – Prevents acid carryover

Fluxing – Prevents oxidation and improves zinc adhesion

Zinc Coating – Metal is coated using the selected galvanization method

Cooling or Quenching – Solidifies the coating

Inspection & Testing – Thickness, adhesion, and uniformity verification

Proper surface preparation is non-negotiable—galvanizing over rust or contamination is ineffective.

Benefits of Galvanization

Galvanization offers a unique balance of performance, cost efficiency, and durability:

Exceptional corrosion resistance

Long service life (25–50+ years in many environments)

Lower lifecycle cost than stainless steel

Minimal maintenance

Excellent impact and abrasion resistance

Full coverage on edges and internal surfaces

Environmentally sustainable and recyclable

For many applications, galvanized steel delivers the best return on investment when long-term durability matters.

How Galvanization Prevents Rust

Galvanization protects steel through:

Barrier protection – blocks corrosive agents

Sacrificial action – zinc corrodes first

Patina formation – zinc carbonate slows further oxidation

Even damaged coatings continue to protect exposed steel—an advantage unmatched by most surface finishes.

Types of Galvanization Methods

Different applications require different galvanization approaches.

Hot-Dip Galvanizing

Steel is immersed in molten zinc (~450 °C), forming a thick, metallurgically bonded coating.

Pros

Thick, durable coating

Cost-effective for large parts

Excellent outdoor performance

Cons

Variable thickness

Not ideal for tight tolerances

Pre-Galvanizing (Mill Galvanizing)

Continuous sheet or coil processing before fabrication.

Best for: Sheet metal, framing, tubing

Limitation: Cut edges require secondary protection

Electrogalvanizing

Zinc applied via electrochemical deposition.

Pros

Smooth, uniform appearance

Precise thickness control

Cons

Thinner coating

Lower corrosion resistance than hot-dip

Sherardizing / Thermal Diffusion Galvanizing

Zinc diffuses into steel at elevated temperatures using zinc powder.

Ideal for

Fasteners

Threads

Complex geometries

Galvannealing

Hot-dip galvanizing followed by annealing to form a zinc-iron alloy.

Advantages

Superior paint adhesion

Excellent weldability

Common in: Automotive manufacturing

Mechanical Plating

Cold process using tumbling and impact bonding.

Best for

Small, heat-sensitive parts

Uniform coating on intricate shapes

Continuous Galvanizing

High-speed zinc coating of steel strips or wires in production lines.

Advantages

High throughput

Consistent quality

Tools and Equipment Used in Galvanization

Zinc baths and kettles

Pickling and flux tanks

Conveyors and cranes

Thickness gauges

Temperature sensors

Ventilation and fume extraction

PPE and safety systems

Key Galvanization Parameters

Critical process variables include:

Zinc bath temperature

Immersion time

Zinc purity

Steel chemistry

Flux concentration

Withdrawal speed

Cooling rate

Environmental conditions

Process control directly determines coating quality and lifespan.

Materials Suitable for Galvanization

Carbon steel

Structural steel

Iron and iron-based alloys

Special consideration is required for high-strength steels due to hydrogen embrittlement risks.

Common Applications of Galvanization

Galvanized materials are used across nearly every major industry:

Construction and structural steel

Infrastructure and utilities

Automotive body panels

Agricultural equipment

Plumbing systems

Industrial machinery

Marine and coastal installations

Electronics and appliances

Galvanization integrates seamlessly with CNC machining, sheet metal fabrication, and welding workflows.

Disadvantages and Limitations

Despite its advantages, galvanization has limitations:

Hydrogen embrittlement risks

Aesthetic constraints

White rust formation

Thickness variation

Post-processing exposure

Understanding these helps ensure correct method selection.

How Long Does Galvanization Take?

Preparation: Several hours

Zinc immersion: Seconds to minutes

Cooling & inspection: Additional time

Continuous lines operate far faster than batch processing.

How Long Does Galvanized Steel Last?

Typical service life:

25–50 years in most environments

50–75 years in rural conditions

Shorter lifespan in marine or industrial settings

Thickness, environment, and maintenance strongly influence longevity.

Galvanized Steel vs Stainless Steel

| Factor | Galvanized Steel | Stainless Steel |

| Cost | Lower | Higher |

| Corrosion Resistance | Moderate–High | Very High |

| Maintenance | Low | Very Low |

| Applications | Structural, outdoor | Medical, marine |

Galvanized steel is often the smarter choice when cost and durability must be balanced.

How to Identify Galvanized Steel

Visible zinc spangle

Gray or matte finish over time

White corrosion products instead of red rust

Reduced spark intensity when ground

Chemical & Physical Properties of Galvanized Steel

Strong atmospheric corrosion resistance

Retains base metal strength

Magnetic

Suitable for moderate thermal exposure

Conclusion

Galvanization remains one of the most reliable and economical methods for protecting steel against corrosion. By selecting the correct galvanization process, manufacturers can dramatically extend product life, reduce maintenance costs, and improve long-term performance.

Whether you are designing structural components, sourcing CNC-machined parts, or selecting surface treatments for industrial equipment, galvanization offers a proven solution that balances performance and cost.

FAQs

- Can galvanized steel rust over time?

Yes, but far slower than untreated steel. Zinc protection significantly delays corrosion. - Can galvanized steel be painted?

Yes, with proper surface preparation and compatible primers. - Is galvanized steel weldable?

Yes, but zinc fumes require ventilation, and post-weld protection is recommended. - Can you galvanize rusty steel?

No. Rust must be completely removed before galvanization. - Is galvanization environmentally friendly?

Yes. Zinc is recyclable, and galvanized steel has a long service life.

Looking for Galvanized or Corrosion-Resistant Metal Parts?

If you need custom CNC machining, sheet metal fabrication, or surface treatment solutions, our engineering team can help you select the optimal material and galvanization method for your application.

Contact us today for a fast technical consultation and quotation.